Method for reinforcing underground mine main chute

A technology for shafts and mines, which is applied in the field of strengthening the main shafts of underground mines where serious collapse occurs. It can solve the problems of large engineering volume, high investment, and the inability to fundamentally solve the long-term stability of the sliding system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

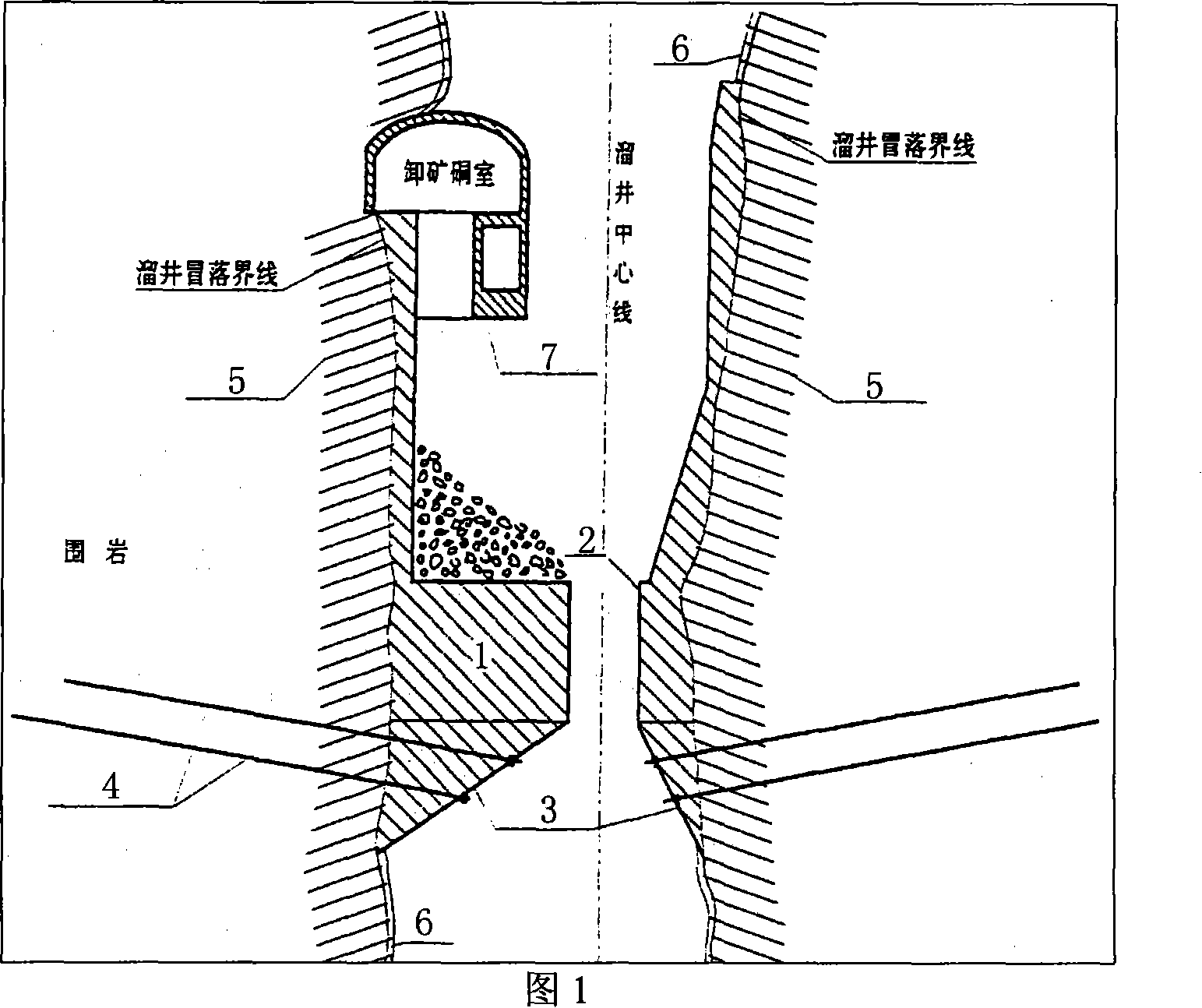

[0013] Two main shafts in an iron mine (1 # and 2 # The main chutes) are each 160m long and the horizontal distance is 24m. Among them, 2 # The main chute collapsed at -360m level, and the section of the chute changed from the originally designed 4.9m 2 , down to 100m 2 , the total amount of collapse reaches 5500m 3 , with 1 # The horizontal distance between the main shafts is only 15.6m.

[0014] 2 # The main chute is reinforced by the "support bucket method" structure, and the specific parameters are:

[0015] (1) The surrounding rock mass of the chute is reinforced with full-length bonded shear anchors and shotcrete. The anchor rod is made of ordinary rebar, and its geometric parameters are: length 1.8m, diameter 22mm, and shotcrete thickness 70mm.

[0016] (2) At the level of -388 meters, a reinforced concrete support column with a funnel mouth diameter of 3m and a height of 8.4m was constructed upwards, and reinforced concrete with a thickness of 300mm was poured...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com