Bomb body structure capable of reducing shock wave drag of bomb body and method thereof

A technology of shock wave resistance and projectile body, which is applied in the direction of self-propelled projectiles, projectiles, offensive equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0108] Embodiment 1. Sleeve-shaped warhead and ammunition

[0109] Figure 2a shows a schematic structural view of a sleeve-shaped warhead, which is composed of a core body 1, a sleeve-shaped body 2 and several ribs 3. The shape of the wall surface of the fin 3 is helical along the central axis 16 of the projectile, and there is an inclination angle with the central axis 16 of the casing-shaped projectile that is the same as the direction of rotation of the rifling. Most of the currently used barrel weapons are rifled barrels. Since the rifling exerts a large force on the projectile to rotate it when the ammunition is fired, the structure of the projectile must be able to withstand such a large force. In order to withstand the powerful force of the rifling, the sleeve casing 2 and the ribs 3 must have sufficient strength. Figure 2b is a schematic diagram of the overall structure of an ammunition equipped with a sleeve-shaped warhead, and Figure 2e is a schematic diagram of the...

Embodiment 2

[0111] Embodiment 2. Sleeve-shaped ammunition integrated with shell and bullet

[0112] FIG. 3 a is a schematic structural view of a sleeve-shaped ammunition with an integrated casing, and FIG. 3 g is a schematic structural view of the front edge of the sleeve casing 2 shrinking inward. The overall structure of the sleeve-shaped ammunition integrated with shell and bullet is made up of sleeve-shaped warhead, bullet holder 4, propellant 5 and base 6 that primer is installed. Its sleeve-shaped warhead is formed as a whole by the core body 1, the sleeve housing 2 and several ribs 3 . The bullet holder 4 is located behind the bullet core body 1, and forms a sealed connection with the bullet core body 1 and the inner wall of the casing casing 2 but does not form a whole; 2 slides back inside and out from the rear of the sleeve housing 2. The structure of the base 6 is equivalent to that part of the bottom left after the cylinder portion in front of the common shell is cut off. T...

Embodiment 3

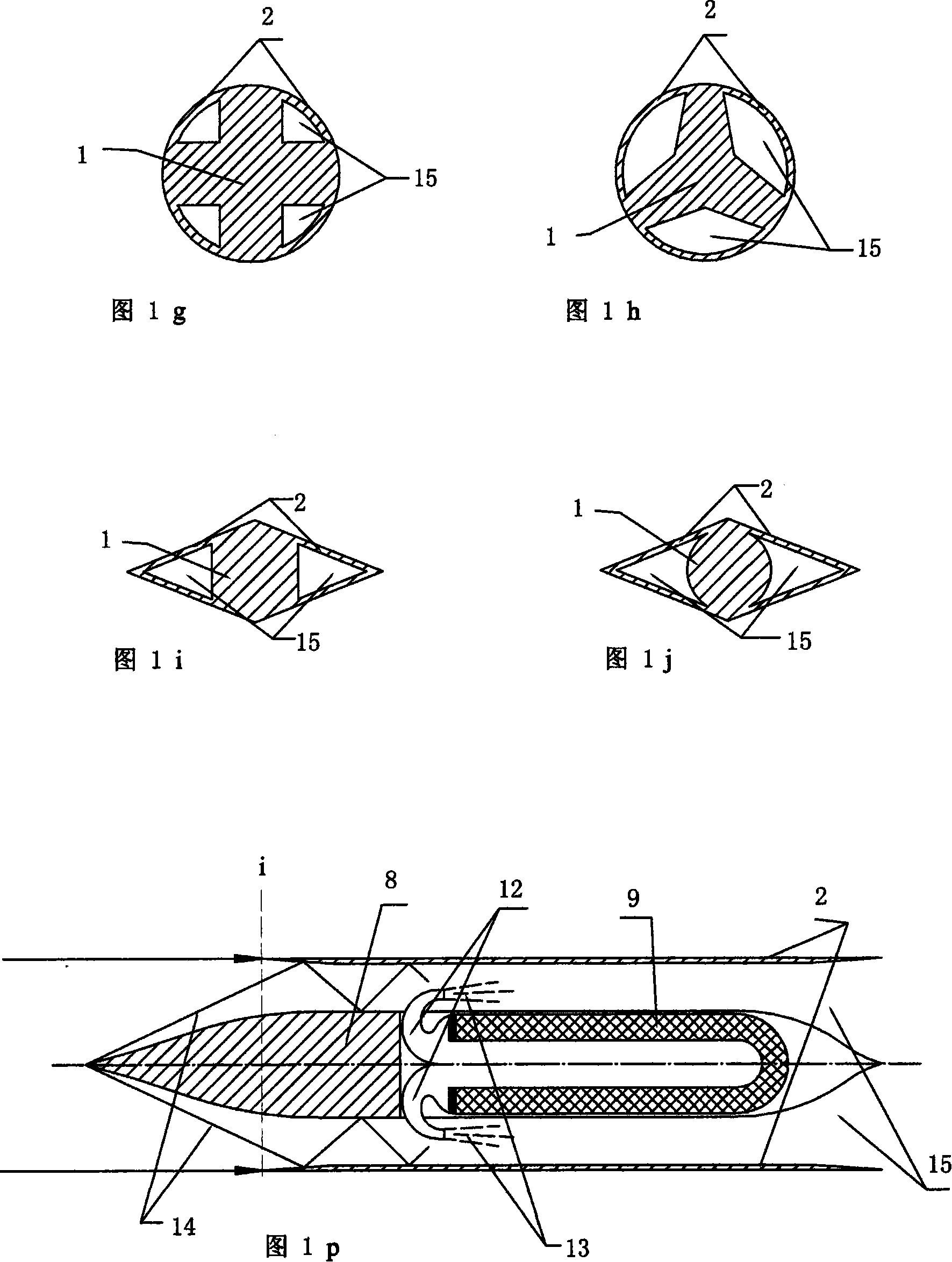

[0117]Example 3. Casing-shaped projectile

[0118] Figure 4a shows the structure of a sleeve-shaped projectile. The core body 1 is composed of a fuze 7 and a warhead 8. The whole bomb consists of a core body 1, a casing shell 2, several ribs 3 and a bullet holder 4. constitute. Figure 4b shows a range-extended sleeve-shaped projectile with a solid motor 9 added. The whole bullet is composed of a core body 1, a sleeve shell 2, several ribs 3, and a bullet holder 4. The core body 1 is composed of a fuze 7, warhead 8, solid motor 9 constitute. The wall surface of the rib 3 can be straight parallel to the central axis 16 of the projectile body, or can be helical with an inclination angle same as the direction of rotation of the rifling between the central axis 16 of the projectile.

[0119] For the positive significance that the sleeve-shaped projectile can produce in the application of large-caliber artillery ammunition, here is a comparison with the domestic PLZ45-155 mm howit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com