Refrigerator evaporator defrost method and defrosting device using the method

An evaporator and freezer technology, applied in the field of refrigeration devices, can solve the problems of refrigerated food soaking, water not draining and overflowing into the refrigerating room, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

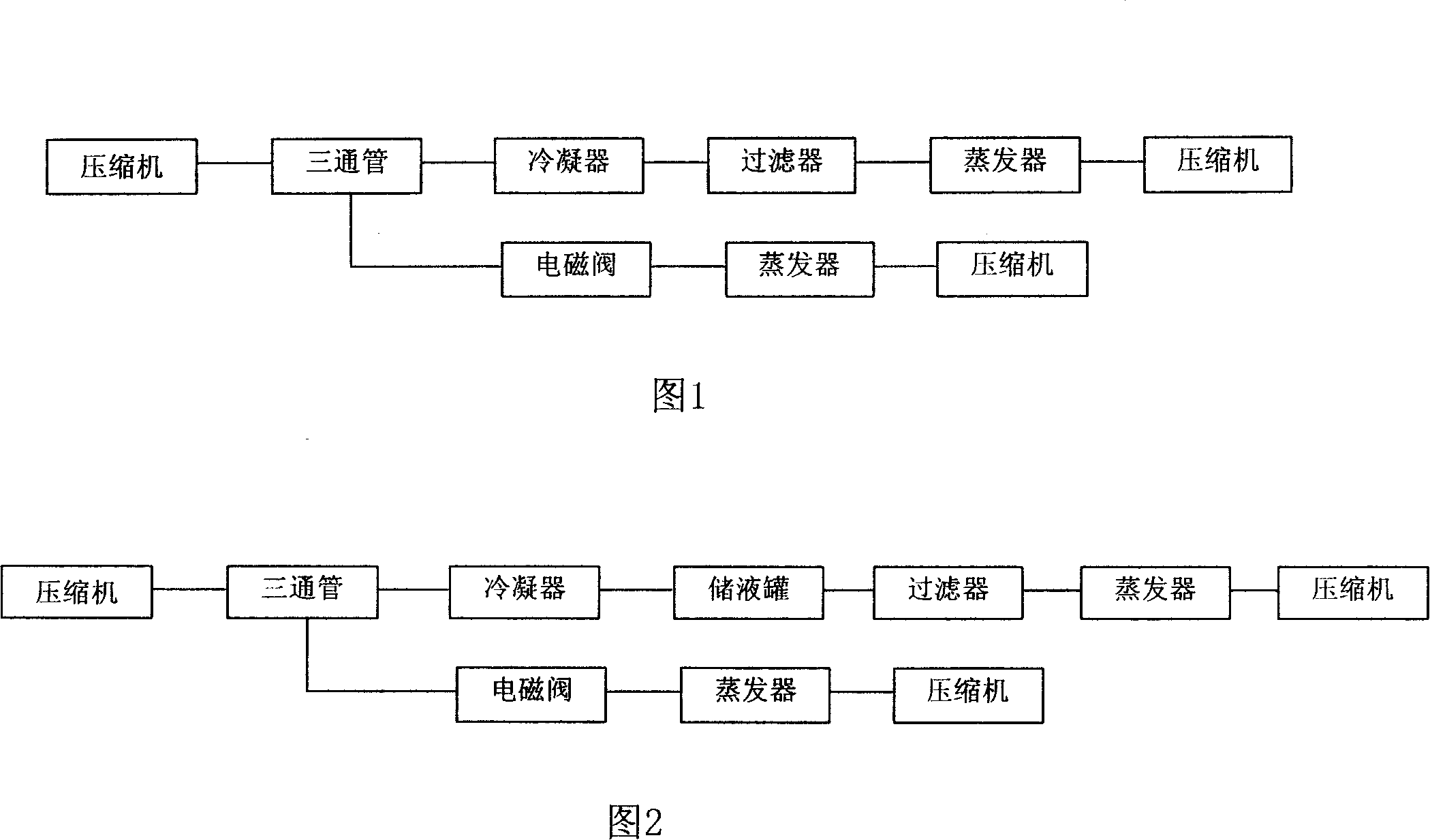

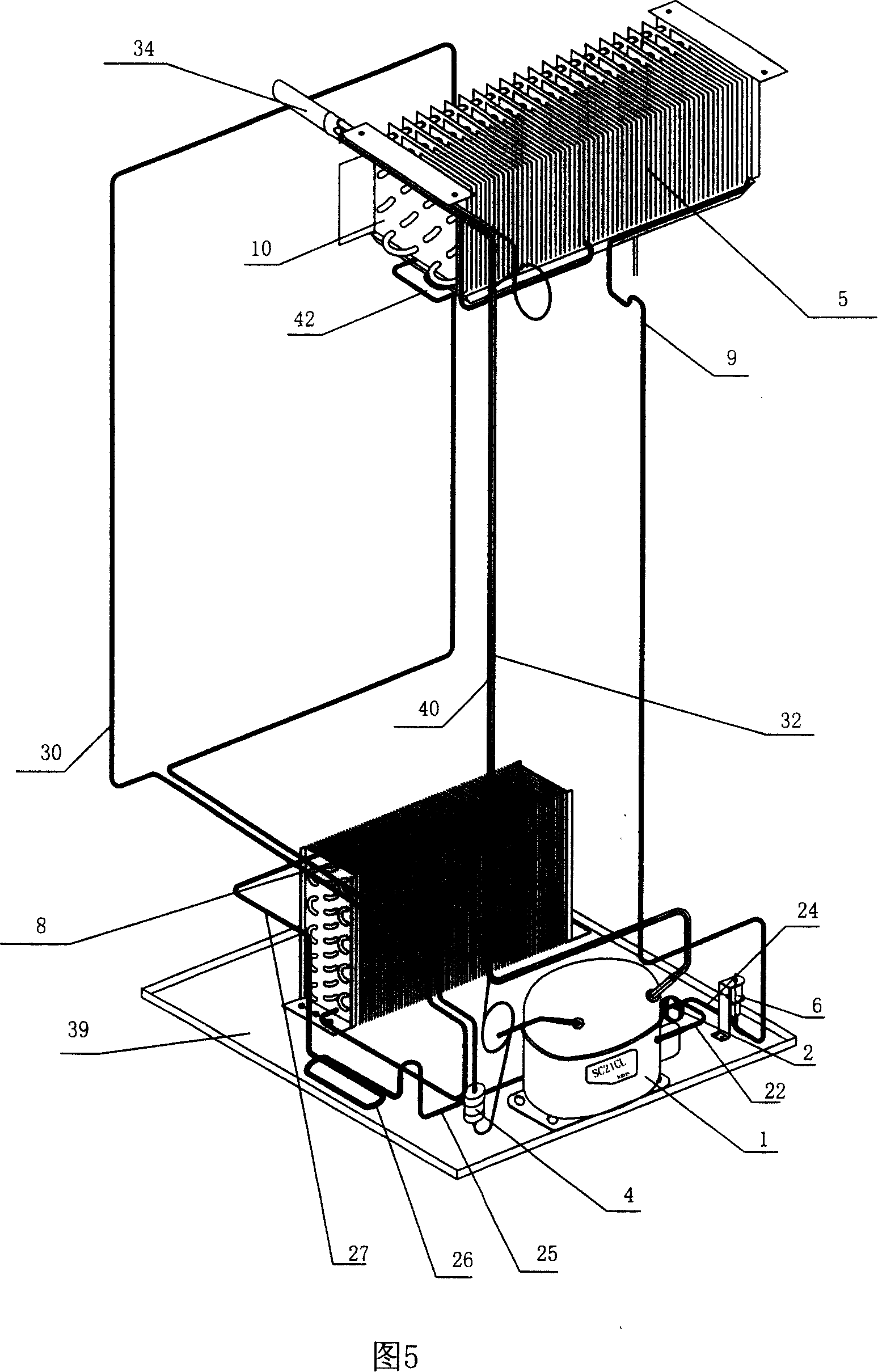

[0033] The invention provides a defrosting method and a defrosting device for an evaporator of a refrigerator, which uses a refrigeration device to defrost the evaporator.

[0034] The defrosting method is the same as the existing method of using the high-pressure and high-temperature refrigerant coming out of the compressor to directly enter the evaporator without going through the condenser to heat and defrost the evaporator. In order to solve the problem that the water cannot be drained due to the blockage of the drain pipe opening of the water pan by the frost formed, the present invention proposes that the high-pressure high-temperature refrigerant should be connected to the water pan and drained from the water pan before entering the evaporator. The tube is heated to melt the ice, the drainage channel is opened, and then the evaporator is defrosted.

[0035] The first method of heating the drain pipe of the water tray to melt the ice is to arrange the hot defrosting pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com