Process for improving the accuracy of manufacturing of precision boring head

A technology for manufacturing precision and boring heads, applied in boring heads, manufacturing tools, metal processing mechanical parts, etc., can solve problems such as difficulty in meeting precision requirements, low manufacturing precision of precision boring heads, and little consideration of errors. Overall manufacturing accuracy, satisfying the effect of boring processing and improving manufacturing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

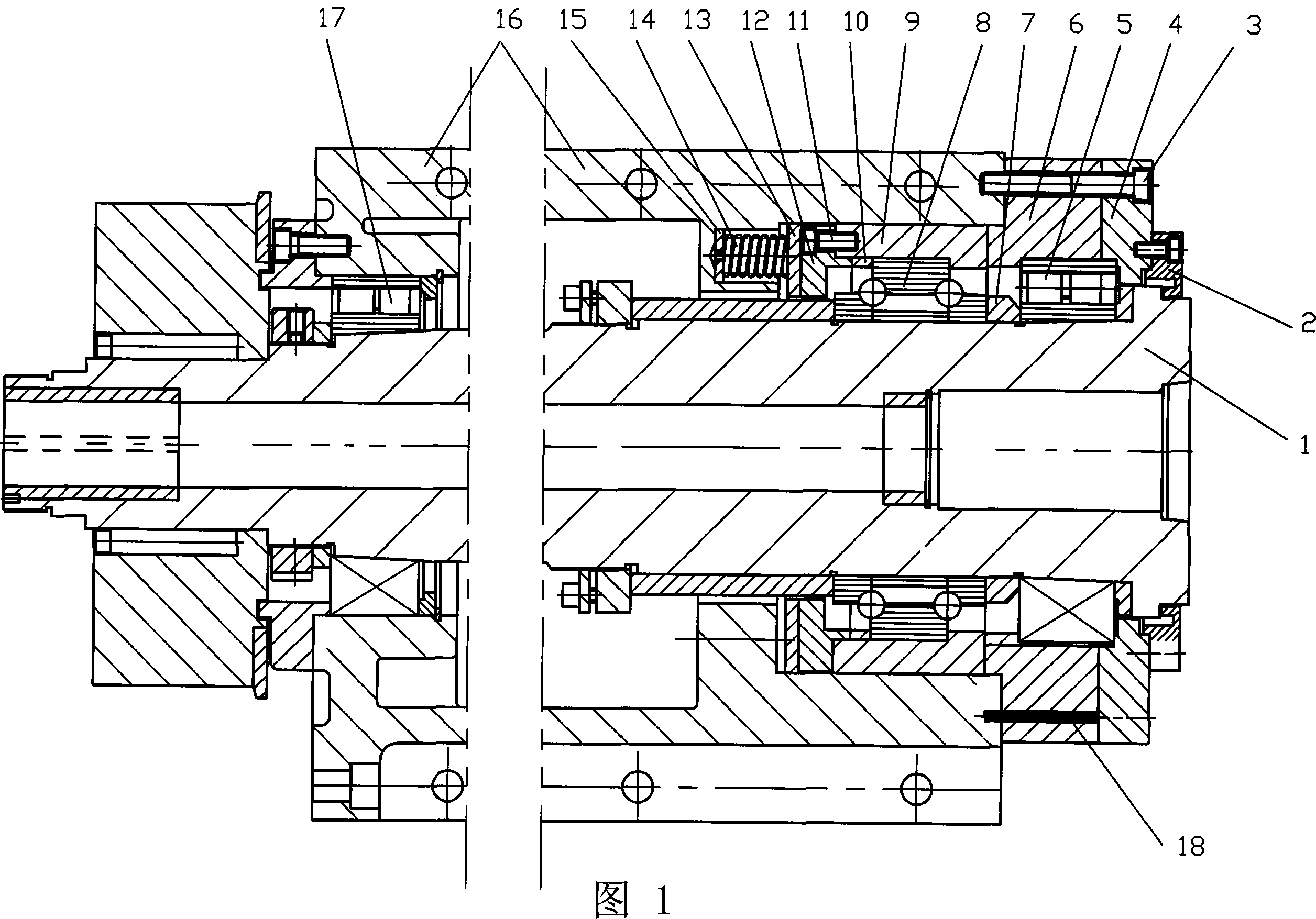

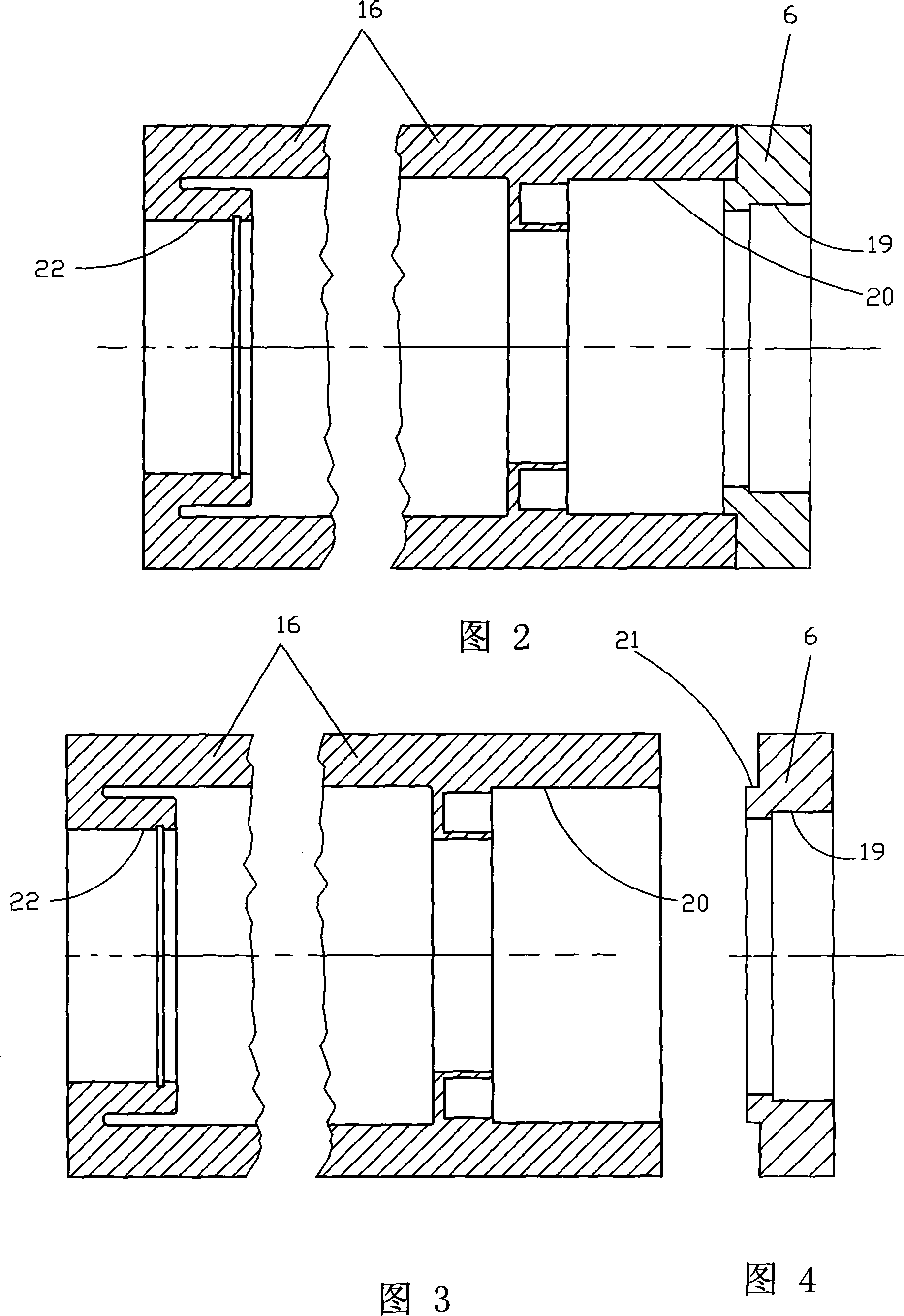

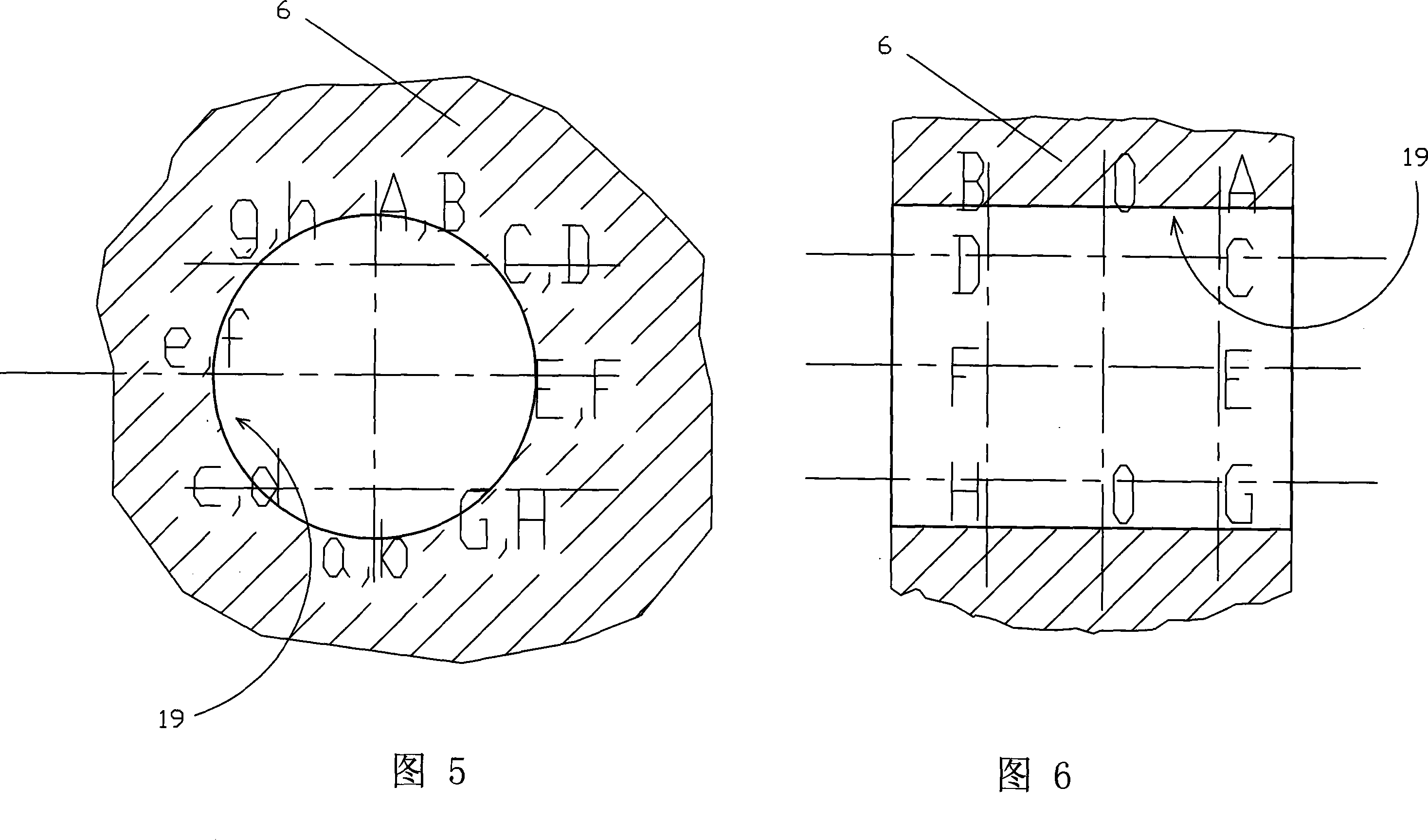

[0019] As shown in Figure 1: 16 is the main shaft housing, adopts casting process and machining molding. Front bearing sleeve 6 and gland 4 are fixed with bolt 3 at the right end of main shaft case 16, main shaft 1 is supported on main shaft case 16 with front bearing 5, intermediate bearing 8, rear bearing 17; The end cover 2 is connected; the intermediate bearing sleeve 9 is provided between the intermediate bearing 8 and the main shaft housing 16; the positioning ring 7 is set on the main shaft 1 between the front bearing 5 and the intermediate bearing 8; the bearing cover 12 is fixed by bolts 11 It is connected to the intermediate bearing sleeve 9 and is provided with a positioning ring 10 between the intermediate bearing 8 and the bearing cover 12; on the inner circumference of the main shaft housing 16, blind holes placed in the spring 14 are evenly distributed, and the washer 13 is located at the right end of the spring 14 Between the bearing cover 12, the left end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com