Optical fiber temp/moisture sensor and manufacturing method and metering installation thereof

A technology of humidity sensor and optical fiber temperature, which is applied in the field of sensors, can solve the problems affecting the performance stability of humidity sensors, insufficient light intensity, and large binding loss, etc., which is beneficial to industrial applications, improves accuracy and sensitivity, and reduces the inter-individual difference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

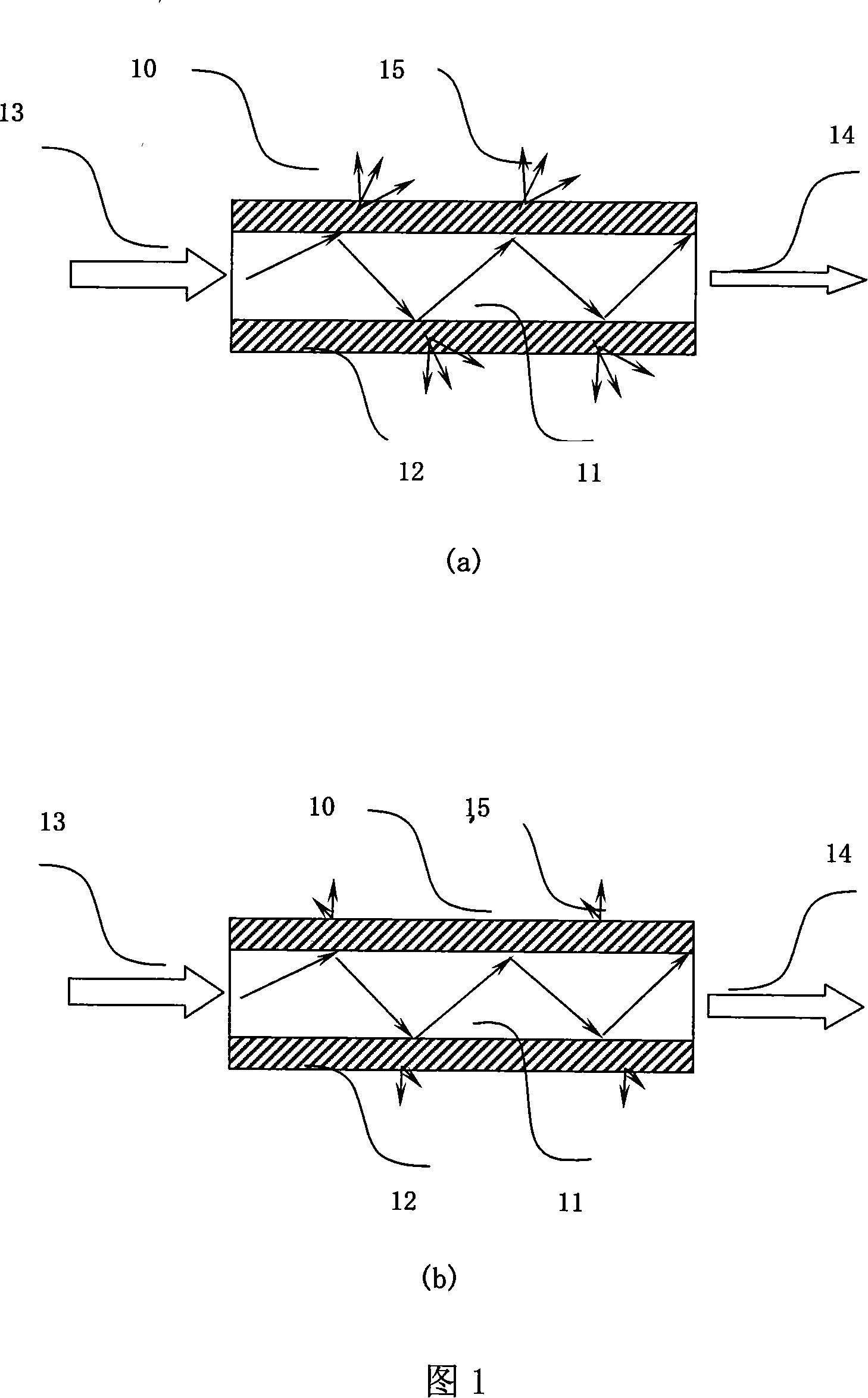

Method used

Image

Examples

Embodiment 1

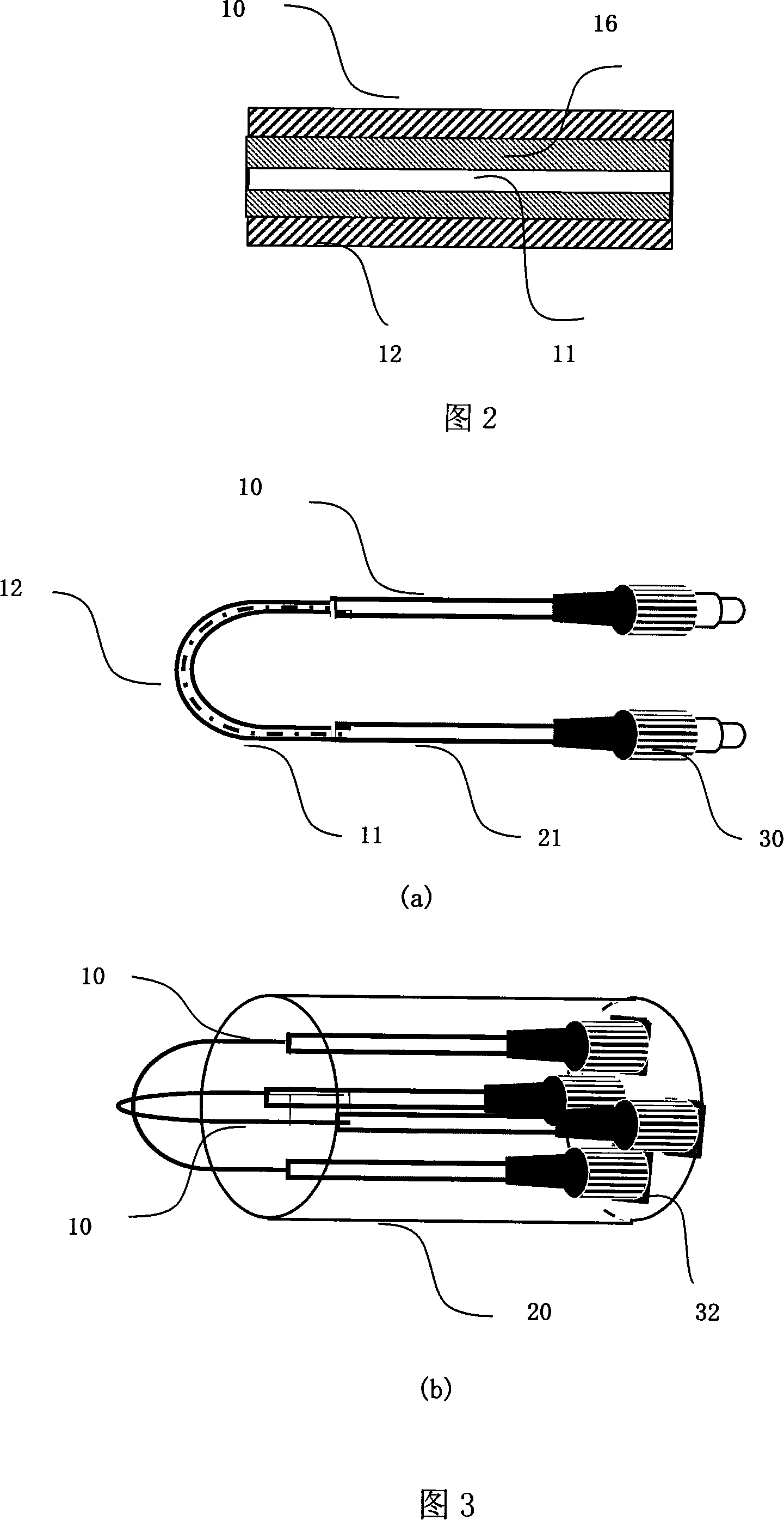

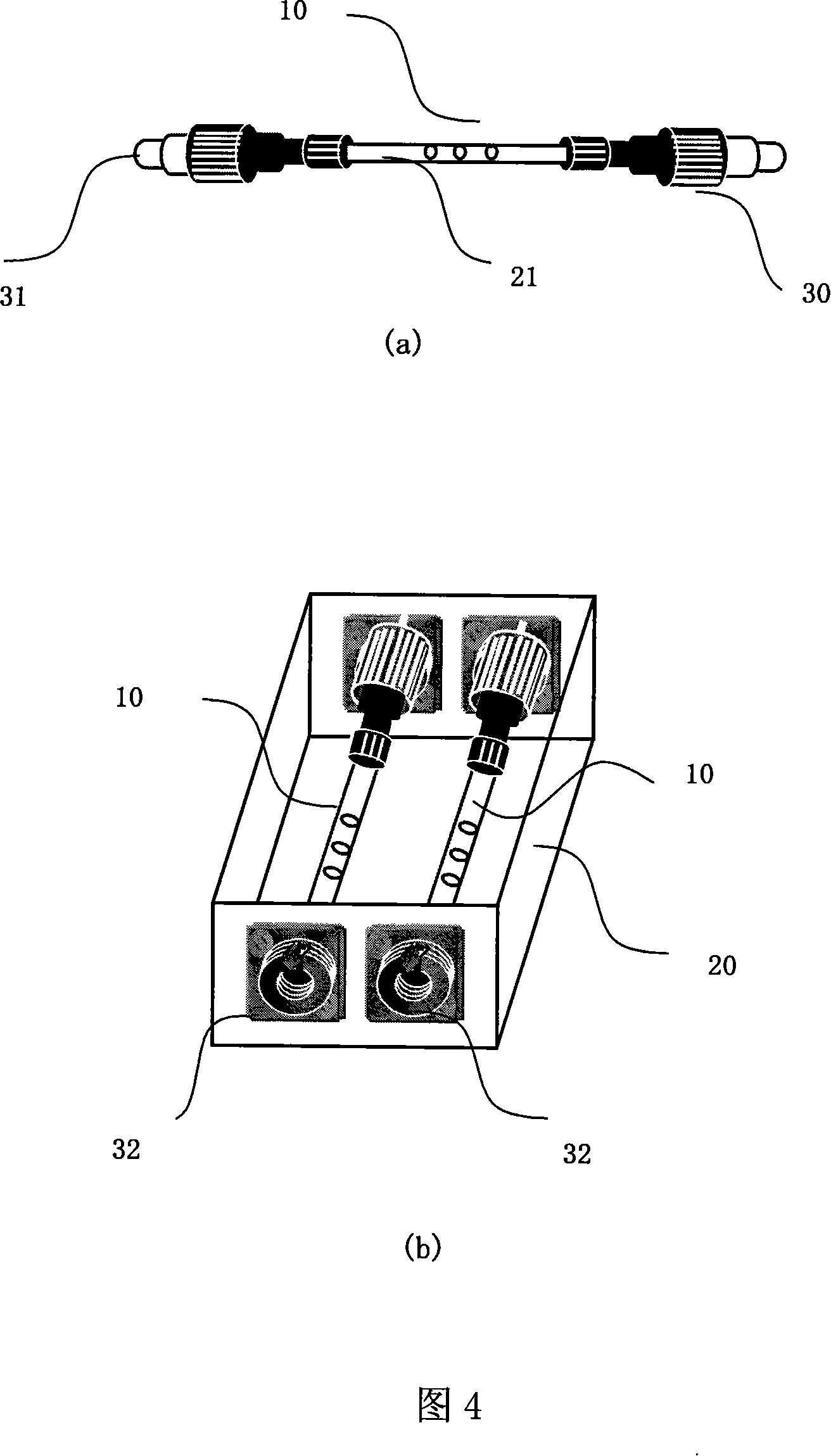

[0127] Cut a glass optical fiber with a core diameter of 200 μm (n=1.46, the diameter including the high polymer reflective layer is 230 μm) into a length of 30 cm, start from a position 2 cm away from one end, and dip the optical fiber in chloroform for 5 minutes , Peel off the high polymer reflective layer about 5cm. Then, heat the solution of polyvinylidene fluoride (PVDF, Tm=175°C, n=1.42) dissolved in cyclohexanone to 100°C and let it cool to 45°C. on the fiber core 11, and kept at room temperature for 10 hours. Afterwards, it is moved into a drying oven, and after heat treatment at 180° C. for 30 minutes in vacuum, a layer of transparent induction cladding layer 12 is formed on the surface of the glass fiber core 11 . Then use an adhesive to bond the two ends of the optical fiber to the ceramic ferrule 31, assemble the FC plug 30, and fully grind the end face of the optical fiber to make a temperature sensor.

[0128] The structure of the sensor testing system is (see ...

Embodiment 2

[0133] Dissolve 10 parts of PVDF and 1 part of polymethylphenylsilane (PMPS, Mw=30000, Tg=230°C, Tm=280°C, n=1.68) in cyclohexanone to prepare a 5% mixed solution, according to The procedure of Example 1 was applied to the same glass core used in Example 1. It was heat-treated at 220° C. for 30 minutes in vacuum. In this mixing ratio, PMPS is reduced to 1.55 under the specified heat treatment conditions, and the refractive index of the sensing cladding layer is 1.43, and an optical fiber temperature sensor is made.

[0134] According to the method of Example 1, after FC plugs are assembled at its two ends, it is placed in a constant temperature and humidity tank 50. Under the conditions of Example 1, the temperature response characteristics of the sensor are evaluated. It can be found that compared with Example 1, It has better temperature response characteristics.

[0135] The O-Si-O bond is formed between the PMPS of the sensor and the glass fiber core, which is integrated...

Embodiment 3

[0137] A PMMA optical fiber with a diameter of 250 μm was cut to a length of 10 cm, dipped in DMSO, and the reflective layer was stripped off. Dissolve 11 parts of PVDF and 2 parts of polymethylphenylsilane (PMPS, Tg=230°C, n=1.68) in cyclohexanone to prepare a 5% mixed solution, and coat it on PMMA according to the method of Example 1 on the fiber core. After vacuum-drying it at 80° C. for 12 minutes, an optical fiber temperature sensor is produced.

[0138] The FC plug 30 is connected to the two ends of the optical fiber temperature sensor with a ceramic ferrule 31, and the end faces are fully ground. This sensor is fixed in the protective box 20 (referring to Fig. 4 (b)), and in the constant temperature and humidity tank 50, the temperature response characteristic of the sensor is evaluated according to the conditions of Example 1, and the result shows that it has the same characteristics as the sensor of Example 1. Equivalent response characteristics.

[0139] In additi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com