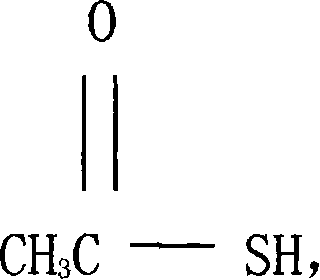

Method of manufacturing thioacetic acid

A technology of thioacetic acid and hydrogen sulfide, applied in the direction of organic chemistry, can solve the problems of low yield, low yield and content, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Sodium sulfide sodium sulfide is produced by using carbon and Glauber's salt;

[0027] First check the airtightness of all operating equipment to ensure that there are no leak points. Put 800 kilograms of industrial acetic anhydride into the 1000L glass-lined reaction tank, and after sealing it, start stirring. Pour two prepared liquids (1300 kg 50% sulfide lye and 2000 kg 30% hydrochloric acid) into the measuring cylinders of sulfide alkali and hydrochloric acid respectively, turn on the gas generator to stir, and put sulfide lye into the gas generator at the same time And hydrochloric acid liquid, at this time will react to generate hydrogen sulfide gas. Open the exhaust valve, pass into the reaction tank through 20 kg of calcium chloride-dried hydrogen sulfide gas, pay attention to keep the reaction temperature in the glass-lined reaction tank, and keep the liquid at 50 ° C, (because the low temperature will affect the reaction speed, the temperature If it is too h...

Embodiment 2

[0031] Sodium sulfide sodium sulfide is produced by using carbon and Glauber's salt;

[0032] First check the airtightness of all operating equipment to ensure that there are no leak points. Put 750 kilograms of industrial acetic anhydride into the 1000L glass-lined reaction tank, and after sealing it, start stirring. Pour two prepared liquids (1250 kg of 50% sulfide lye and 1950 kg of 30% hydrochloric acid) into the measuring cylinders of sulfide alkali and hydrochloric acid respectively, turn on the gas generator to stir, and put sulfide lye into the gas generator at the same time And hydrochloric acid liquid, at this time will react to generate hydrogen sulfide gas. Open the exhaust valve, pass into the reaction tank through 19 kg of calcium chloride-dried hydrogen sulfide gas, pay attention to keep the reaction temperature in the glass-lined reaction tank, and keep the liquid at 55 ° C, (because the low temperature will affect the reaction speed, the temperature If it is...

Embodiment 3

[0036] First check the airtightness of all operating equipment to ensure that there are no leak points. Put 850 kilograms of industrial acetic anhydride into the 1000L glass-lined reaction tank, and after sealing it, start stirring. Pour two prepared liquids (1350 kg 50% sulfide lye and 2050 kg 30% hydrochloric acid) into the measuring cylinders of sulfide alkali and hydrochloric acid respectively, turn on the gas generator to stir, and put sulfide lye into the gas generator at the same time And hydrochloric acid liquid, at this time will react to generate hydrogen sulfide gas. Open the exhaust valve, pass into the reaction tank through 21 kg of calcium chloride-dried hydrogen sulfide gas, pay attention to keep the reaction temperature in the glass-lined reaction tank, and keep the liquid at 60 ° C, (because the low temperature will affect the reaction speed, the temperature If it is too high, it will be difficult to ventilate, and a bumping accident will occur) After reactin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com