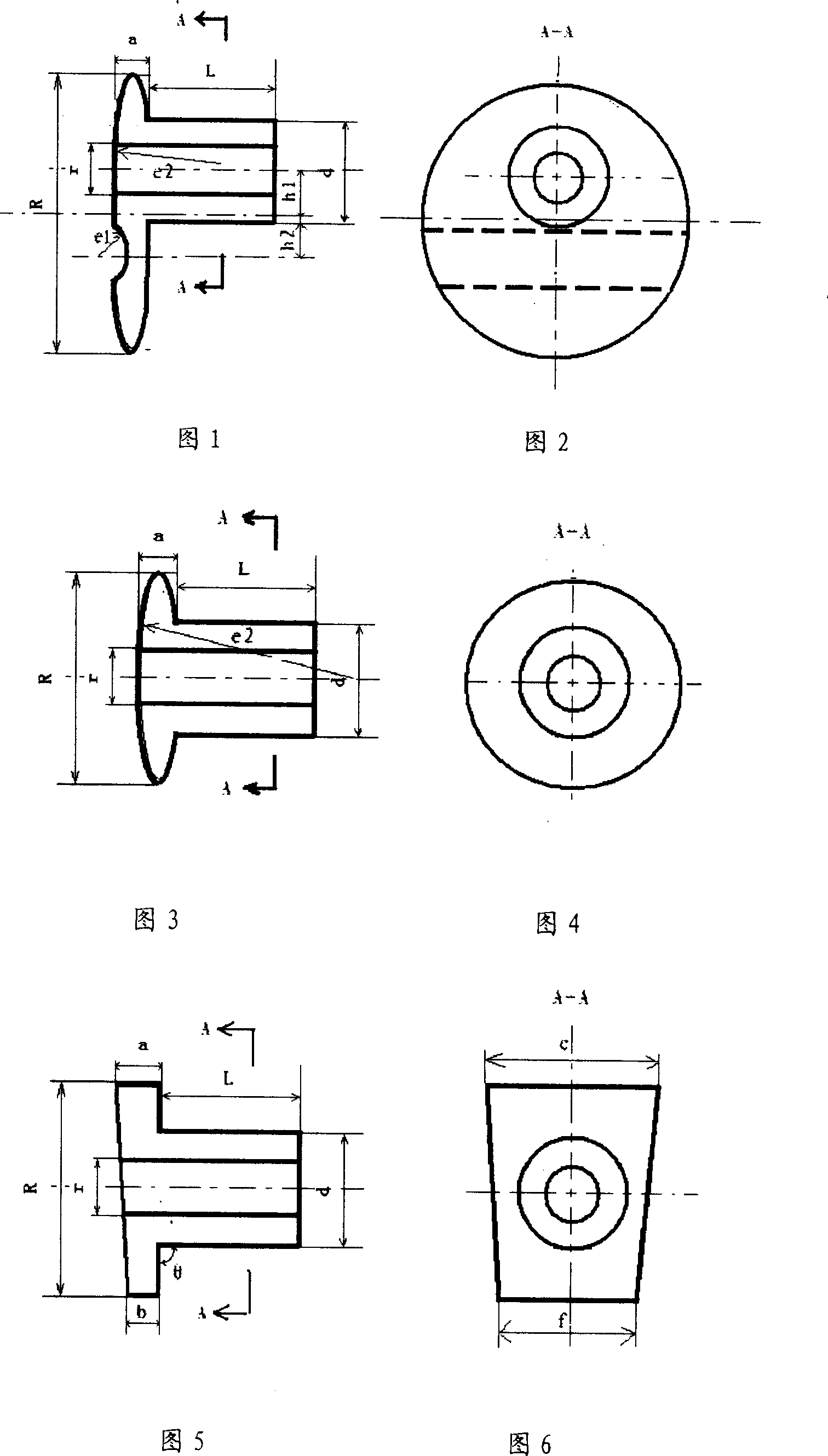

HAP/HDPE compound artificial ossicula auditus and method of preparing the same

An ossicle and artificial technology, applied in bone implants, medical science, prostheses, etc., can solve the problems of osteoconductive ossicle displacement and prolapse without osteoinductivity, and achieve good biological activity and no adverse effects. Reaction, coefficient of friction, impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] ①The analytically pure Ca(NO 3 ) 2 (or CaCl 2 ) and (NH 4 )H 2 PO 4 (or H 3 PO 4 ) were respectively dissolved in deionized water to form a solution, and mixed at a speed of 500-2000 rpm at a molar ratio of 5:3, and mixed with NaOH or NH 4 O) adjusting the pH value of the solution in the range of 7.4 to 12, stirring for 2 to 16 hours, and aging for 1 to 3 days. The obtained precipitate is filtered, and sintered at 300° C. to 900° C. for 5-10 hours to prepare HAP nanoparticles.

[0024] ②The prepared HAP nanoparticles and HDPE are directly mixed in a mechanical stirrer with a mass percentage ratio of HAP:HDPE=5:95 to obtain a HAP / HDPE mixed powder;

[0025] ③Put the HAP / HDPE composite powder directly into the mixer for mixing. The mixing temperature is 160-220°C, raise the temperature of the injection machine to 160-220°C, add the mixed HAP-HDPE composite powder into the barrel of the extruder, at 160-220°C, 30-60r / min Extrusion is carried out to make a predete...

Embodiment 2

[0027] ① The main raw materials used are metal Ca (analytical pure), absolute ethanol (analytical pure), phosphoric acid (chemical pure). Metal Ca was put into heated ethanol, nitrogen gas was passed, and stirring was continued for 4h. The reactant was quenched in an ice bath to obtain a Ca(OEt)2 solution. According to Ca / P=167, prepare phosphoethanol solution. Slowly add phosphoric acid ethanol solution dropwise to the Ca(OEt)2 solution at a temperature lower than 10°C, and the reaction will generate ACP. Its reaction formula is:

[0028] Ca+2EtOHN2Ca(OEt)2+H2↑10Ca(OEt)2+6H3PO4+2

[0029] H2OEtOH=Ca10(PO4)6(OH)2↓+20EtOH

[0030] After being fully reacted, it was decomposed with nitrogen gas and stirred for 24 hours. The solution containing the white gel was separated and the precipitate was lyophilized. After the ethanol is basically volatilized, it is dried in an oven at 100°C for 8 hours, ground, and sieved.

[0031] ②Mix HAP nanoparticles and HDPE with HAP mass perc...

Embodiment 3

[0034] ①The analytically pure Ca(NO 3 ) 2 (or CaCl 2 ) and (NH 4 )H 2 PO 4 (or H 3 PO 4 ) were respectively dissolved in deionized water to form a solution, and mixed at a speed of 500-2000 rpm at a molar ratio of 5:3, and mixed with NaOH or NH 4 OH adjusts the pH value of the solution in the range of 7.4-12, and after stirring for 0-16 hours, aging for 0-3 days. The obtained precipitate is then put into an autoclave, treated at 150-250° C. and at a speed of 0-300 rpm for 2-10 hours, and then washed, filtered and dried to obtain hydroxyapatite nanoparticles.

[0035] ② Dissolve HDPE in decahydronaphthalene solvent, then add HAP nanoparticles, make HAP nanoparticles and HDPE with mass percent ratio HAP:HDPE=20:80, fully stir the solution to disperse and mix the particles in the solution evenly, remove Solvent to make HAP / HDPE mixed powder.

[0036] ③The uniformly mixed powder is molded into a green body, sintered at 220°C, then cooled to room temperature, and then mach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole radius | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com