Method of preparing meat chocolate

A meat food and chocolate technology, which is applied in the field of meat food chocolate preparation, can solve the problem of single eating form of chocolate and few chocolates, etc., and achieve the effects of good visual effect of appearance, improvement of edible grade, and good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

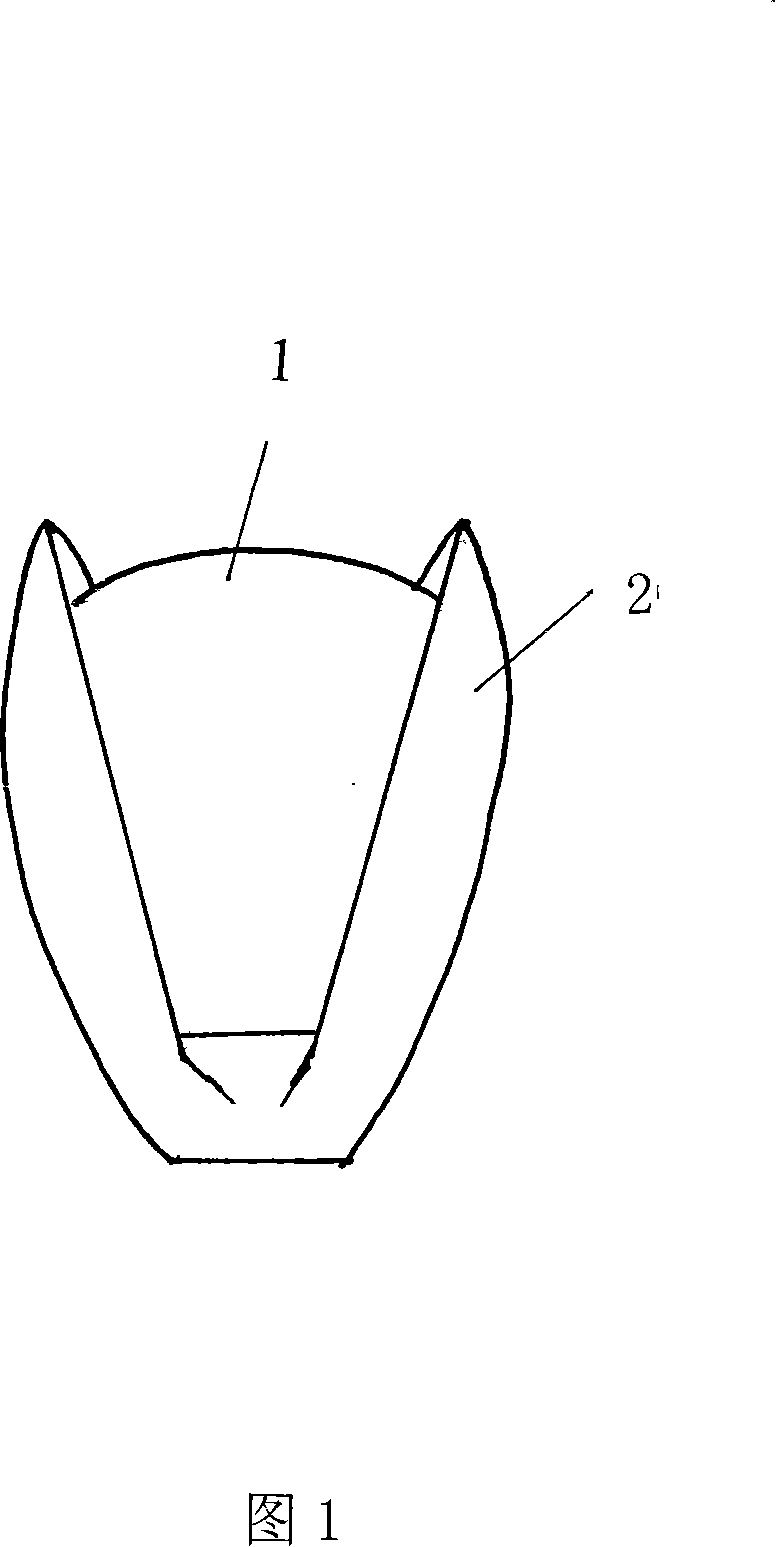

Image

Examples

example 1

[0014] Remove the shells from the shrimp, crush the shrimp meat into minced meat, and make shrimp balls. After boiling in water to shape, drain the water, air shower, place in a stainless steel plate, and freeze quickly at -40°C until the center temperature is lower than -20°C. ℃, and then placed in a Virtis-12L (imported from the United States) vacuum drying chamber, first vacuum dehydration at -28 ℃ to a water content of 30%, and then vacuum dehydration at -15 ℃ for 10 hours, then heat up to 15 ℃ for vacuum dehydration 5 Hours, dehydrate to 2% water content;

[0015] 2) After melting the chocolate block at 45°C, pour it into a PE plastic sheet model with a thickness of 0.01mm, and mold the chocolate after cooling;

[0016] 3) Dip a little chocolate syrup on the bottom of the dehydrated shrimp balls, and then take two pieces of molding chocolate to inlay on both sides, the lower part is combined with the chocolate paste on the bottom of the shrimp balls, and the upper part is...

example 2

[0018] 1) Skim the beef cubes, age them, and place them on a stainless steel plate. The size of the beef cubes depends on your needs. Quickly freeze at -28°C until the center temperature is lower than -18°C, then place it in a vacuum drying chamber, first vacuum dehydrate at -28°C to a water content of 30%, then vacuum dehydrate at -15°C for 10 hours and then heat up to Vacuum dehydration at 15°C for 5 hours, until the water content is below 3%;

[0019] 2) After melting the chocolate block at 45°C, pour it into a PE plastic sheet model with a thickness of 0.01mm, and mold the chocolate after cooling;

[0020] 3) Dip a little chocolate pulp on the bottom of the dehydrated beef cubes, and then take two pieces of shaped chocolate to inlay on both sides. The lower part is combined with the chocolate pulp on the bottom of the beef cubes, and the upper part is opened at a certain angle to make the dehydrated beef light yellow and fragrant. The grains are exposed, combined with cho...

example 3

[0022] 1) Soak sea cucumbers in 3% salt water for 5-10 hours, grill them in microwave until they are ripe, rinse them with water to remove the salt, drain them and air-drain them to remove the surface moisture, place them in a stainless steel plate, and freeze them quickly at -28°C until the center temperature is lower than - After 20°C, put it in a vacuum drying chamber, vacuum dehydrate to a moisture content of 20%, then vacuum dehydrate at -15°C for 10 hours, and vacuum dehydrate at 15°C for 5 hours to reach a moisture content of 3%.

[0023] 2) Take the shape of dehydrated and dried sea cucumber to make a copper plate model, take a PE plastic plate with a thickness of 0.01mm and make it into a sea cucumber-shaped PE mold sheet, take a candy-free chocolate block and melt it at 45°C, and pour it on the PE plastic sheet model After cooling, it becomes sea cucumber-shaped chocolate.

[0024] 3) Dip a little chocolate syrup on the bottom of the dehydrated sea cucumber, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com