Method for refining waste lubricating oil and device thereof

A waste lubricating oil and equipment technology, applied in the field of waste lubricating oil re-refining, can solve the problems of high energy consumption for lubricating oil regeneration, cracking of lubricating oil, high distillation temperature, etc., and achieve the effects of reducing energy consumption, reducing pollution and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

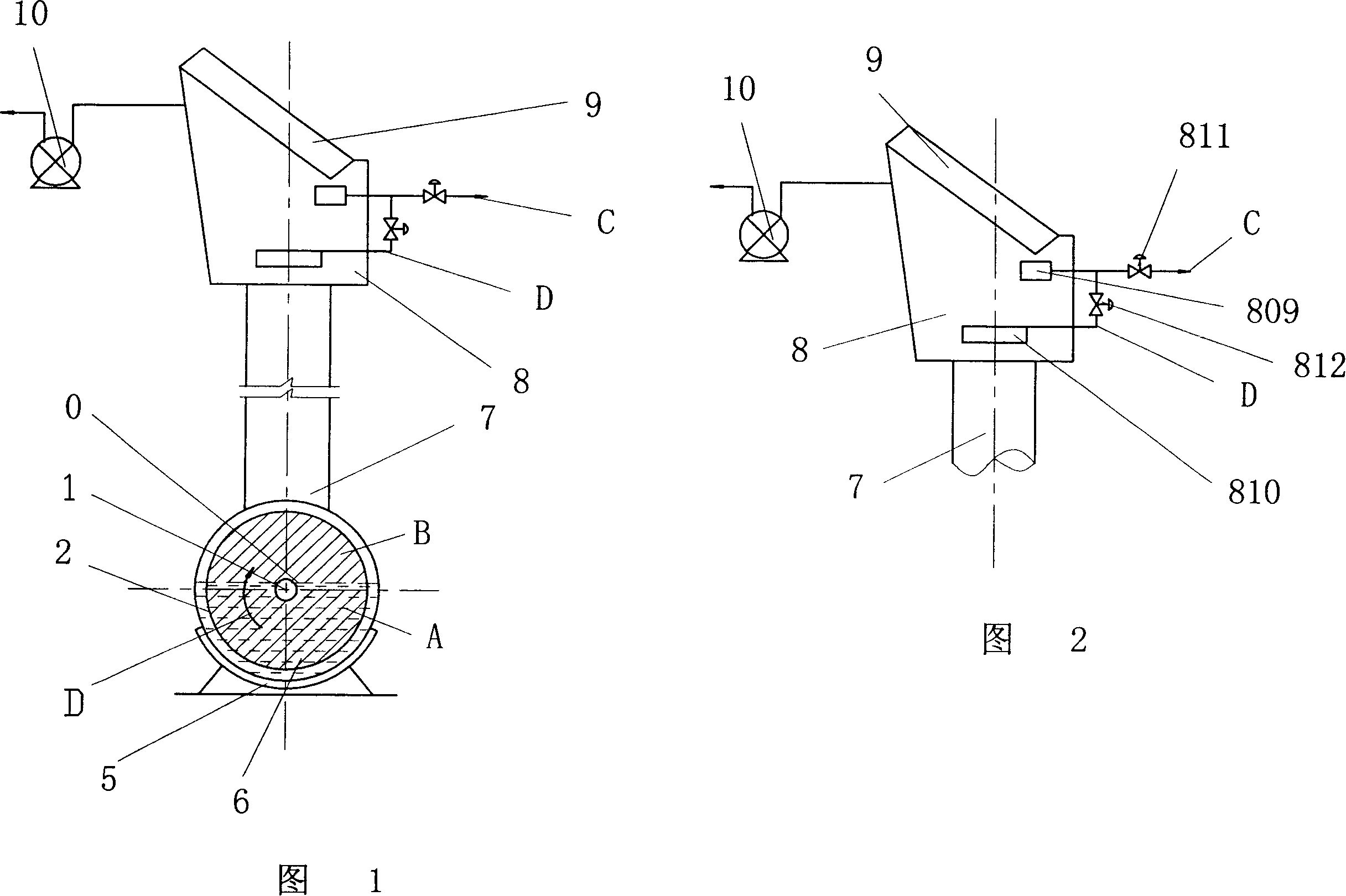

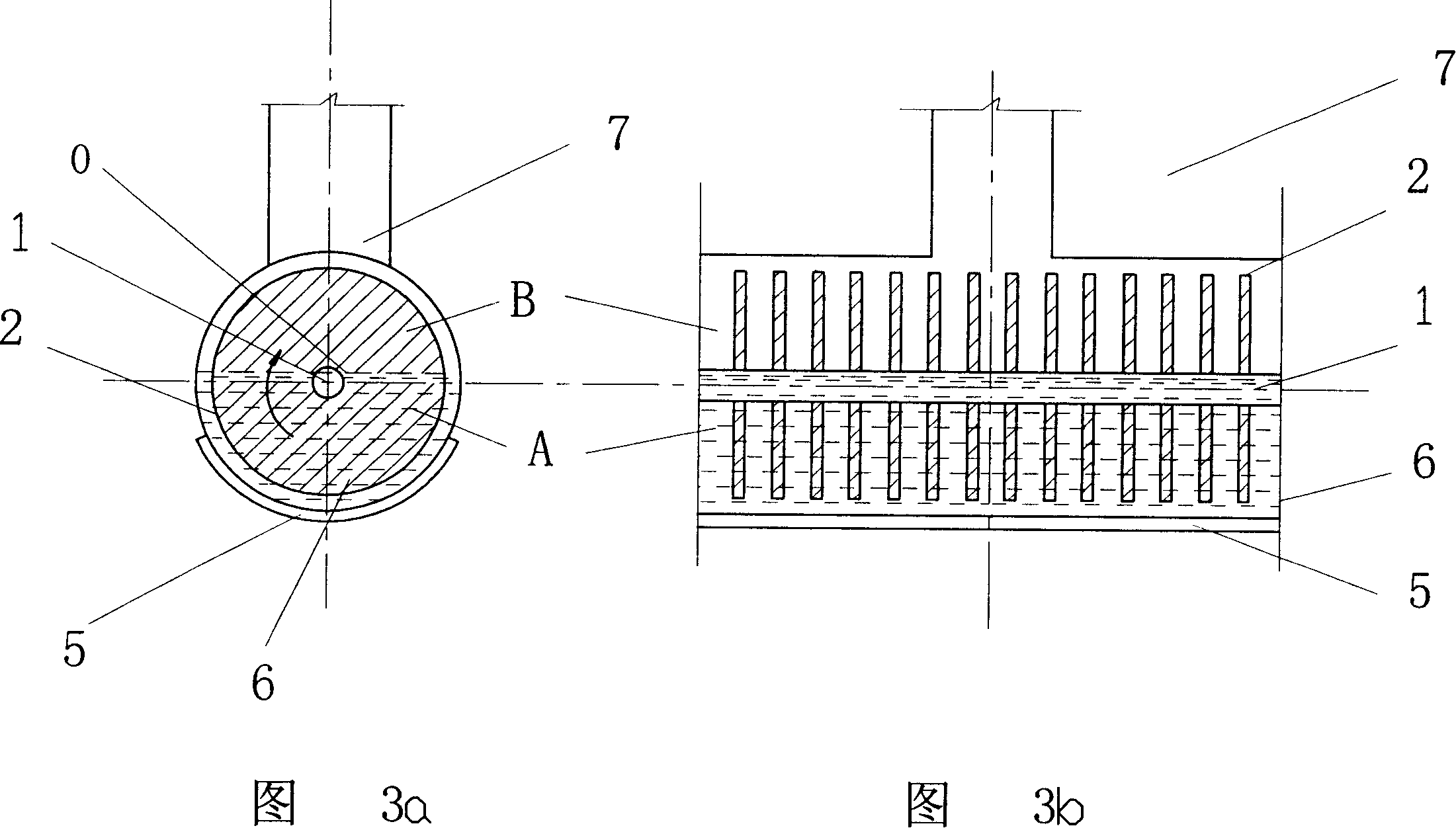

[0064] Embodiment 1: Waste diesel engine lubricating oil is refined again with the method of the present invention.

[0065] Put the black ink-like waste diesel engine lubricating oil into the impurity removal container with a glass pipe below for simple dehydration and impurity removal. Weigh 100Kg of waste diesel engine lubricating oil after de-impurity, join in the vacuum film-attached volatilization still shown in Figure 3 a and Figure 3 b of the volatilization rectification tower as shown in Figure 1 of the present invention, seal still mouth, pump Vacuum to 5-50Pa, start the driving device of the main shaft 1, and make the rotary vane 2 rotate at a speed of 90 rpm. Raise the temperature of the kettle to 170°C-220°C. The volatilized gas that produces lubricating oil flows to the tower section 7. The number of trays of the column packing is 18, and after the mass transfer and exchange of the packing, the volatile gas flows to the top condenser to condense. The temperatu...

Embodiment 2

[0069] Embodiment 2: Regeneration of waste vacuum pump oil.

[0070] Vacuum pump oil is also a kind of lubricating oil, and it is one of the special lubricating oils.

[0071] The following is an example of SV-6 waste mechanical vacuum pump oil regeneration:

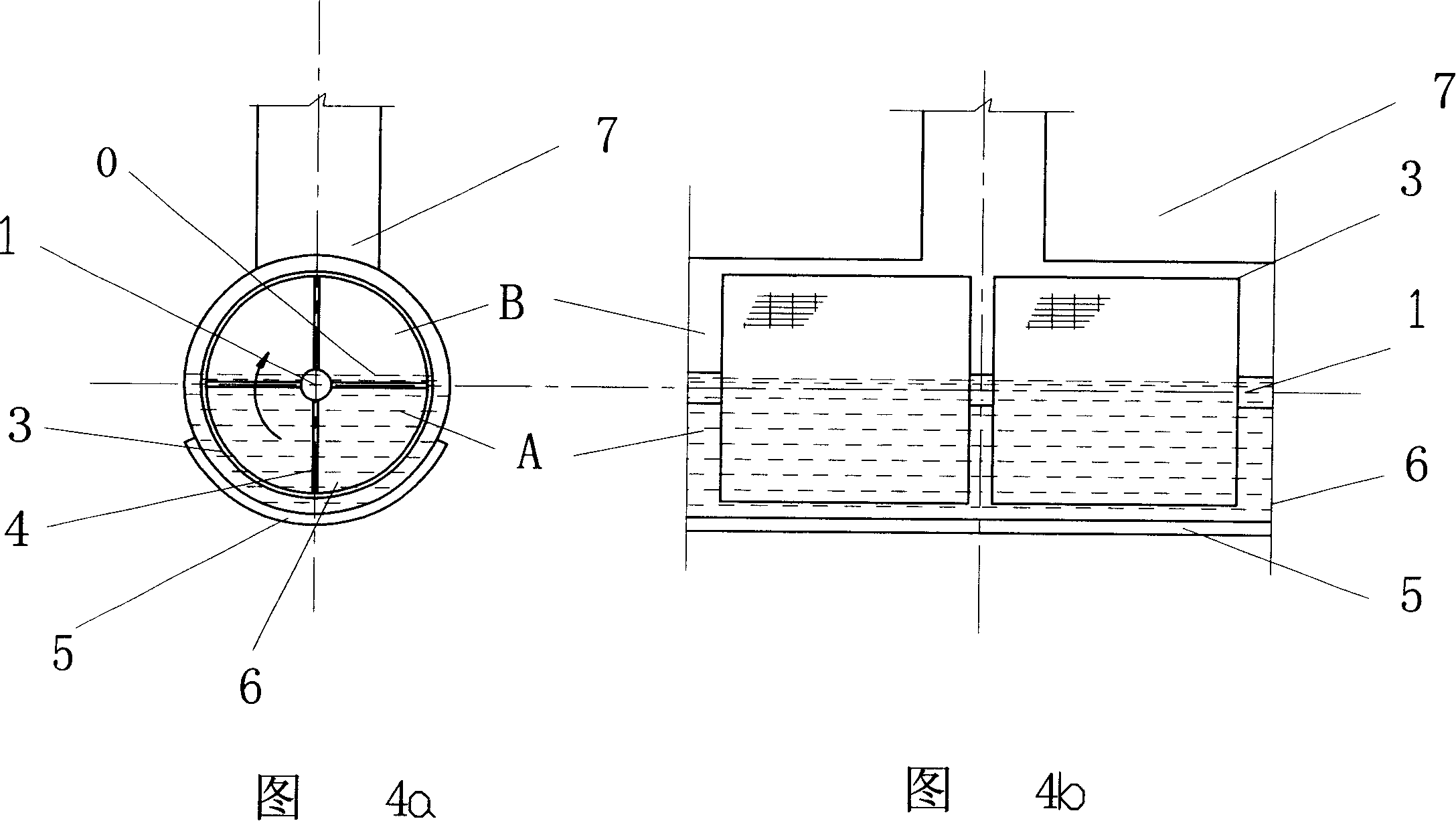

[0072] The waste SV-0-6 waste mechanical vacuum pump oil is dehydrated and de-impured in the same way as in Example 1. Weigh 100Kg and put it into the vacuum film-attached volatilization kettle shown in Figure 4a and Figure 4b of the tower shown in Figure 1, evacuate to 10-50Pa, start the driving device of the main shaft 1, and make the cage 3 rotate at a speed of 60 rpm. Raise the temperature of the kettle to 200°C-265°C. The volatilized gas that produces lubricating oil flows to the tower section 7. The number of trays of the column packing is 2, and after the mass transfer and exchange on the packing, the volatile gas flows to the top of the tower and is condensed by the top condenser. The temperature at the top ...

Embodiment 3

[0076] Embodiment 3: Refining of waste gasoline engine lubricating oil again

[0077] The jet black waste gasoline engine lubricating oil is dehydrated and removed with the same pretreatment method as in Example 1. Weigh 100kg of the waste gasoline engine oil after de-impurity, join in the tower still of the volatilization rectification tower as shown in Figure 1 of the present invention, seal the mouth of the still, evacuate to 50-95Pa, start the driving device of main shaft 1, Make rotary vane 2 rotate, and the rotating speed is 130 revs / min. Raise the temperature of the kettle to 170-200°C. The volatile steam that produces lubricating oil flows to tower section 7. The number of trays of the column packing is 16, and after the mass transfer and exchange of the packing, the volatile gas flows to the top condenser to condense. The temperature at the top of the tower is 70-110°C. The condensed fraction was partly refluxed (reflux ratio 0.9:1) and partly withdrawn. Produce ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com