Magnesium-base layer-shaped composite material and its composite casting preparation method

A composite material and composite casting technology, applied in metal layered products, chemical instruments and methods, metal material coating technology, etc., can solve the problems of poor comprehensive mechanical properties, corrosion damage of magnesium alloys, etc. Variety, the effect of excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

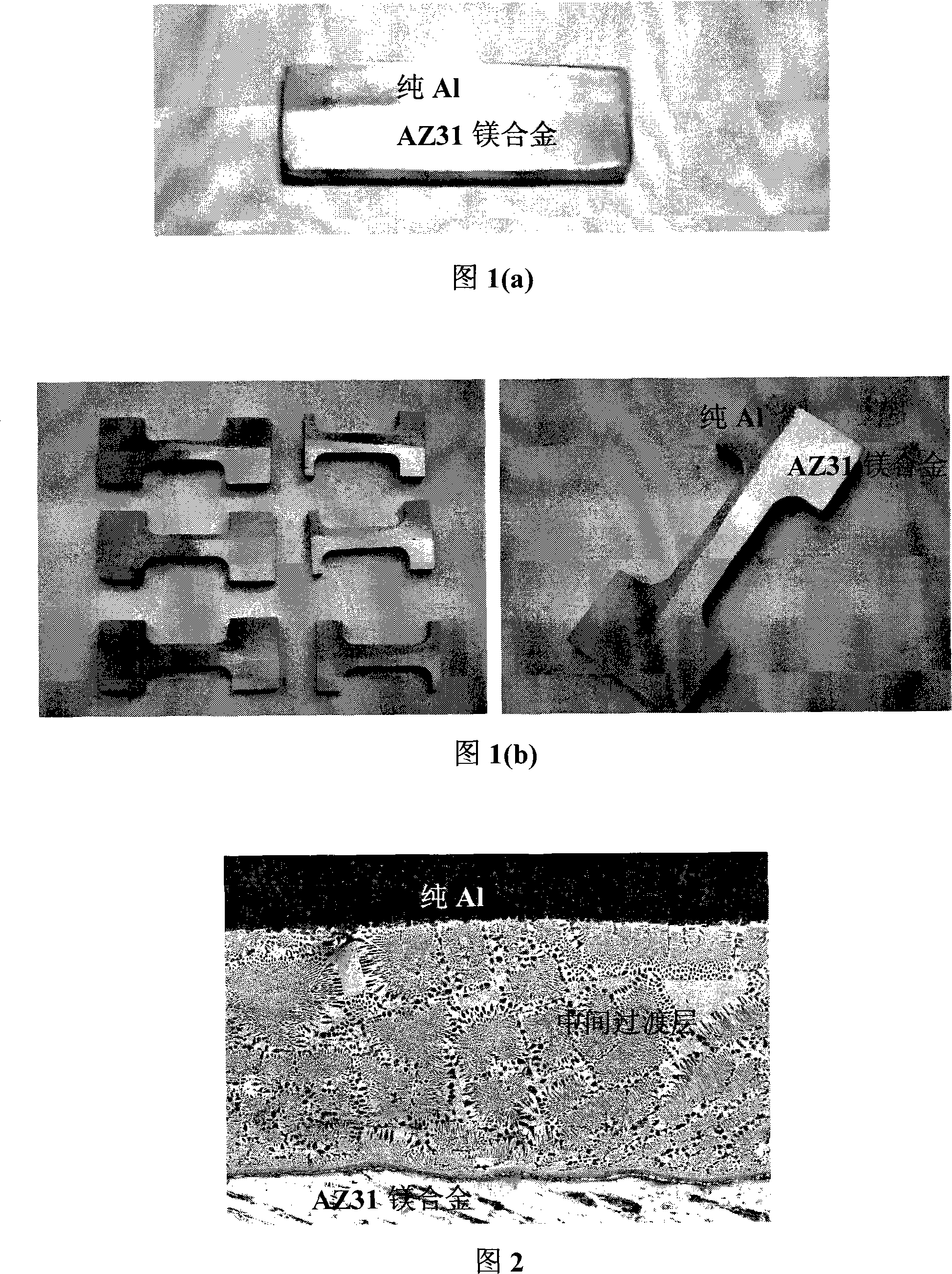

[0051] In this example 1, the design material: AZ31 magnesium alloy / pure aluminum layered composite material, the thickness of the AZ31 magnesium alloy layer is 18mm, the thickness of the pure aluminum layer is 12mm, and the interface contact area is 100×60mm 2 .

[0052] New material design principles: As a lightweight engineering material, magnesium alloys are weaker in strength and plasticity than aluminum alloys. In addition, most commercial magnesium alloys have poor corrosion resistance, while aluminum alloys naturally form a dense oxide film, which has excellent corrosion resistance and self-healing function. Therefore, magnesium / aluminum layered composites can greatly solve the corrosion problem of magnesium alloys. By preparing the magnesium / aluminum layered composite material, the advantages of the magnesium alloy and the aluminum alloy can be combined to meet the needs of more occasions and expand the application of the magnesium alloy.

[0053] Preparation techno...

Embodiment 2

[0065] The difference from Example 1 is:

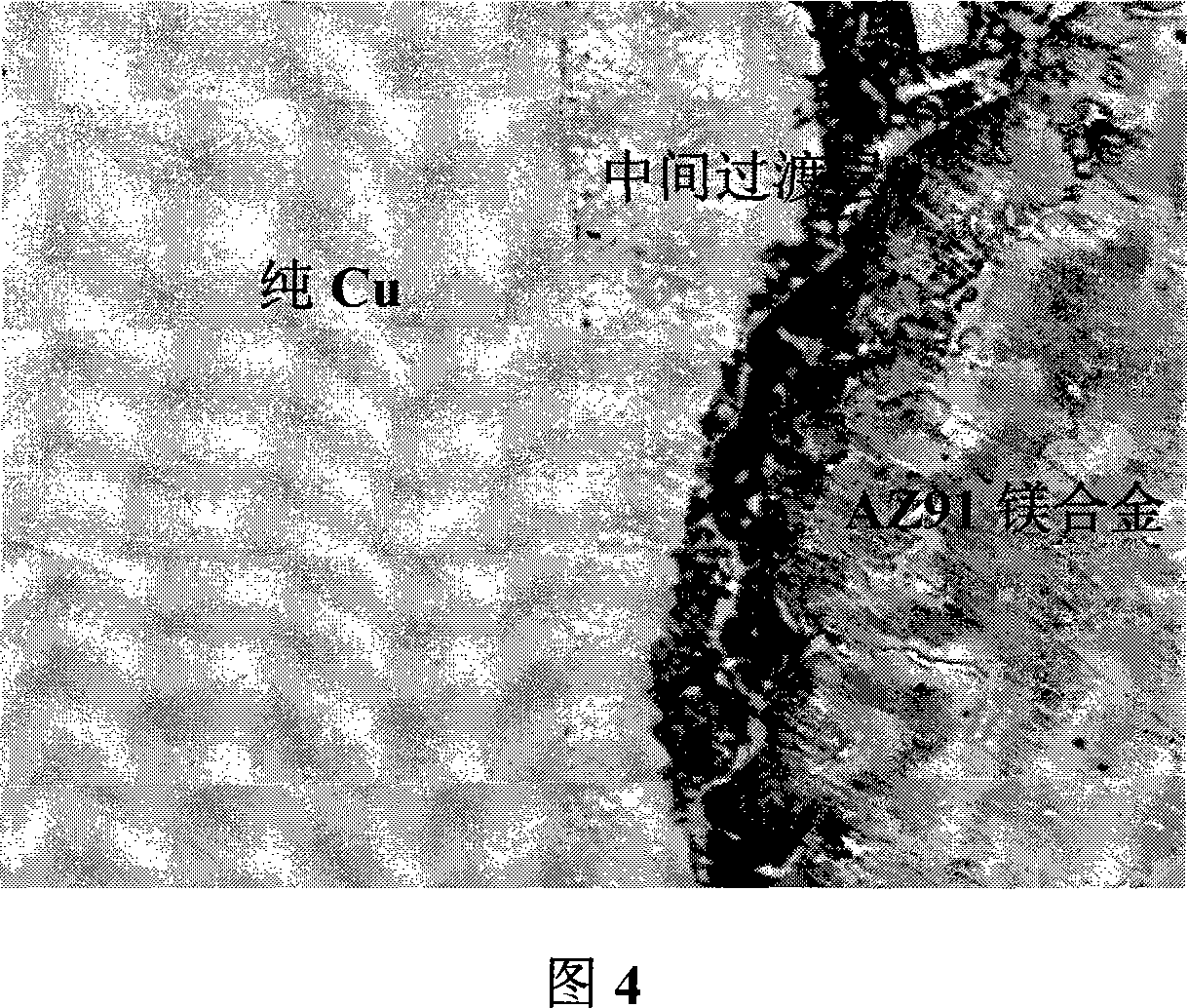

[0066] In Example 2, the design material is AZ91 magnesium alloy / pure Cu layered composite material, the thickness of the AZ91 magnesium alloy layer is 100mm, the thickness of the pure copper layer is 3mm, and the interface contact area is 80×60mm 2 .

[0067] New material design principle: Combining the light weight of magnesium alloy and the excellent electrical and thermal conductivity of copper.

[0068] Preparation technology: liquid / solid composite metal mold gravity casting, the specific operation steps are as follows:

[0069] I), alloy composition:

[0070] Alloy

Grade

Element content (nominal weight %)

Magnesium (Mg)

Aluminum (Al)

Zinc (Zn)

Manganese (Mn)

Copper (Cu)

AZ91

margin

9

1

0.3

0

Cu

0

0

0

0

100

[0071] II), the specific steps of liquid / solid composite casting:

[0072] 1) Pre-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com