Method for manufacturing imitating jade tap and its product and mould

A production method and faucet technology, which are applied to sliding valves, valve details, multi-way valves, etc., can solve the problems of affecting the water outlet flow of the faucet, easily broken and damaged, and difficult to dismantle the mold, and achieve diversified appearance and color, low cost, and production. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] The technological process of the manufacturing method of this imitation jade faucet is as follows:

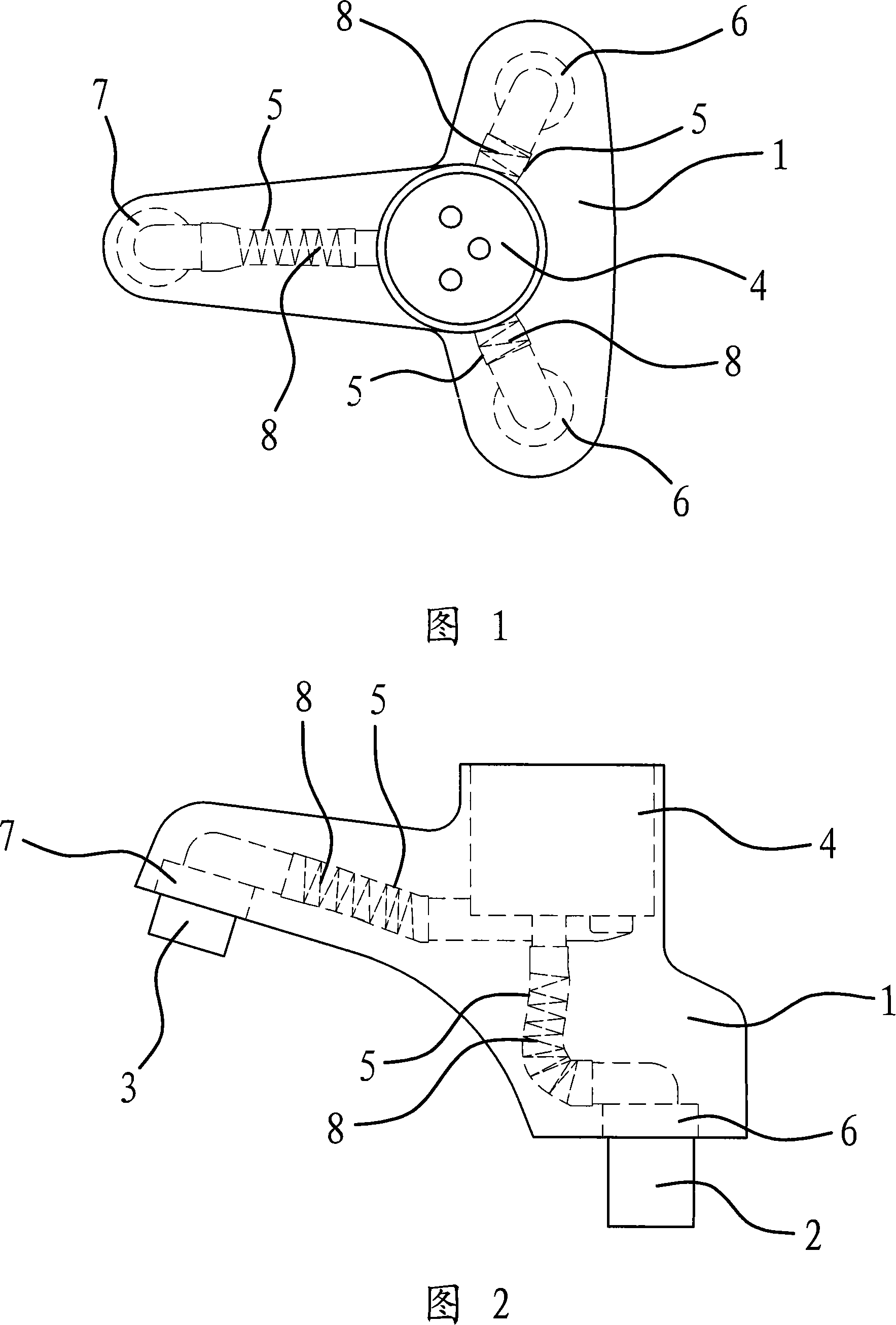

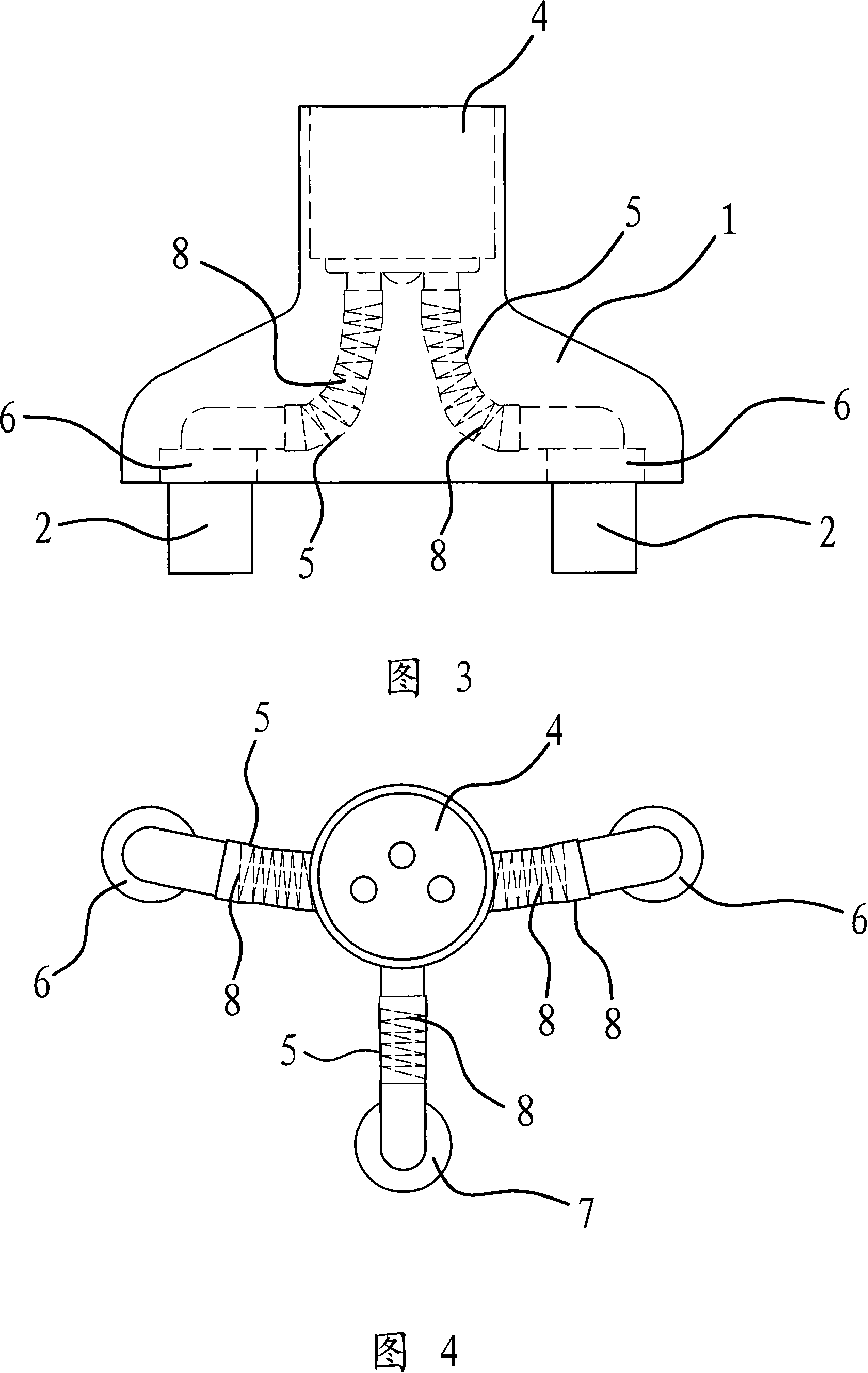

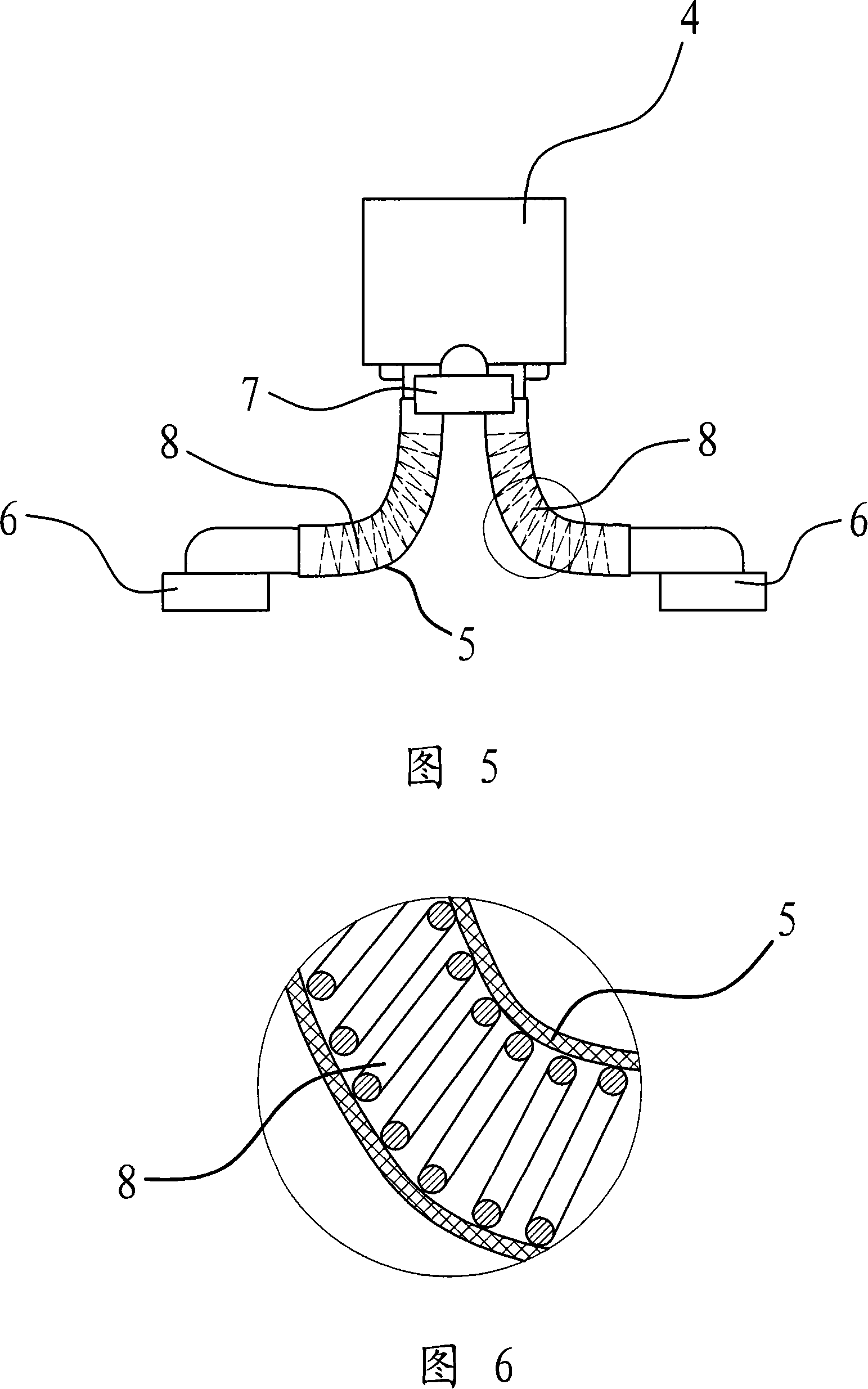

[0066] A. Parts production: parts of imitation jade faucet, including connecting pipe 5, spring 8, valve core seat 4, water inlet seat 6, water outlet seat 7, water inlet pipe 2, water outlet pipe 3, valve cover, pressure cap, valve Core, handle. Among them, the spring 8, the water inlet pipe 2, the water outlet pipe 3, the valve cover, the pressure cap, the valve core, the connecting pipe 5, and the handle are ordinary parts, which can be made by general processing technology, or can be directly purchased in the market:

[0067] Use wood to make the same model as valve core seat 4, water inlet seat 6, and water outlet seat 7, make a wooden frame with wood, and install the above-made models of valve core seat 4, water inlet seat 6, and water outlet seat 7 on the wood. On the wooden board of the frame, the feeding trough is made of wooden strips, and the various models a...

Embodiment 2

[0073] In the present embodiment, the prepared imitation jade material according to Example 2 in Table 1 is melted and injected into the mold, and the curing time is 5 minutes.

Embodiment 3

[0075] In this embodiment, the prepared imitation jade material according to Example 3 in Table 1 is melted and injected into the mold, and the curing time is 20 minutes.

[0076] Table 1: the composition of the imitation jade material that the present invention adopts (by weight)

[0077]

[0078] Wherein the resin described in Example 1 is unsaturated polyester resin agate S-793C; the filler is aluminum hydroxide; the accelerator is cobalt naphthenate; the pigment is a general organic colorant ; Described catalyst is methyl ethyl ketone peroxide.

[0079] The resin described in Example 2 is unsaturated polyester resin 196; the filler is glass powder; the accelerator is cobalt naphthenate; the pigment is a commercially available organic colorant; the The catalyst is methyl ethyl ketone peroxide.

[0080] The resin described in Example 3 is unsaturated polyester resin agate S-793C; the filler is aluminum hydroxide and glass powder, and the weight ratio of the two is 5:5; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com