Enrofloxacin gelatine microball and its preparation method

A technology of enrofloxacin and gelatin, which is applied in the directions of pharmaceutical formulations, medical preparations containing active ingredients, and bulk delivery, can solve the problems of reduced drug treatment effect, increased drug residues, toxic and side effects, etc., and achieves a round shape. , good dispersion, less adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

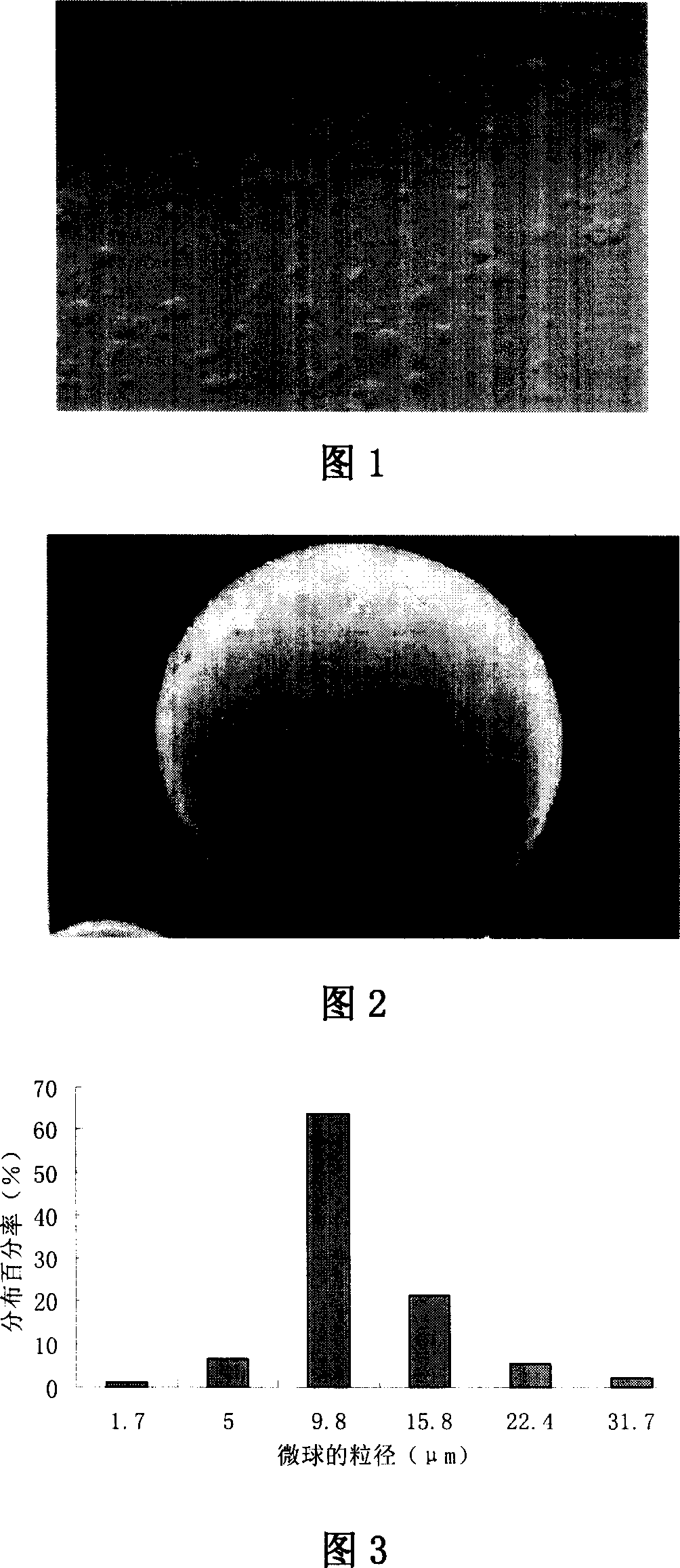

[0027] The preparation method of enrofloxacin gelatin microspheres proposed by the present invention, the specific steps are as follows: take gelatin and add double distilled water or phosphate buffer solution, completely swell in a warm water bath, then add enrofloxacin to mix and dissolve, and then drop Add it into a beaker containing Span 80 (or Span 60) and liquid paraffin, stir evenly in a water bath at the same temperature, continue to stir for a certain period of time until it becomes milky white, cool down rapidly in the ice bath to below 5°C and continue to emulsify, then add pentadiene The aldehyde continued to stir to cross-link and solidify, dehydrated and stirred with isopropanol, and filtered with suction. Then wash with a little isopropanol, wash off the glutaraldehyde, wash off the liquid paraffin on the surface of the microspheres with petroleum ether, and dry in vacuum to obtain a slightly yellowish microsphere powder with good roundness;

[0028] In this met...

Embodiment 1

[0034] Get 0.4g of gelatin, add 4mL of double-distilled aqueous solution (to make a gelatin solution with a weight volume concentration of 10%), swell completely in a warm water bath at 60°C, then add 0.2g of enrofloxacin, mix and dissolve (enrofloxacin in water The weight-volume concentration in the oil phase is 5%), and then added dropwise to the 100mL beaker filled with 0.6mL Span 80 and 30mL liquid paraffin (Span 80 is 2.0% in the oil phase by volume concentration). The medium electromagnetic stirring is even, the stirring speed is 1000r min -1 , stirred for 15 minutes until milky white, cooled rapidly in an ice bath to below 5°C, continued to stir and emulsify for 15 minutes, added 3 mL of glutaraldehyde in a thin stream, continued to stir for cross-linking and solidification for 30 minutes, dehydrated with 30 mL of isopropanol and stirred for 10 minutes, and suction filtered. Then wash with a little isopropanol to remove the glutaraldehyde, wash off the liquid paraffin o...

Embodiment 2

[0037] Take 0.4g of gelatin, add 0.9mol·L -1 pH 5.0 phosphate buffer solution 4mL (prepared 10wt% gelatin solution), swell completely in a warm water bath at 60°C, then add 0.4g enrofloxacin, mix and dissolve, then dropwise add 0.6mL Span 80 and 30mL In a 100mL beaker of liquid paraffin (Span 80 volume concentration 2.0%), electromagnetically stir evenly in a water bath at the same temperature, and the stirring speed is 700r min -1 , stirred for 15 minutes until milky white, cooled rapidly in an ice bath to below 5°C and continued to emulsify for 15 minutes, added 3 mL of glutaraldehyde in a thin stream and continued to stir for cross-linking and solidification for 30 minutes, dehydrated with 30 mL of isopropanol and stirred for 10 minutes, and filtered with suction. Then wash with a little isopropanol to wash away the glutaraldehyde, wash off the liquid paraffin on the surface of the microspheres with petroleum ether, and dry in vacuum overnight to obtain a yellowish microsp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com