Defoaming method for the foam well drilling

A foam and defoaming technology, applied in drilling composition, foam dispersion/prevention, chemical instruments and methods, etc., can solve problems such as non-recyclable, non-recyclable foam, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

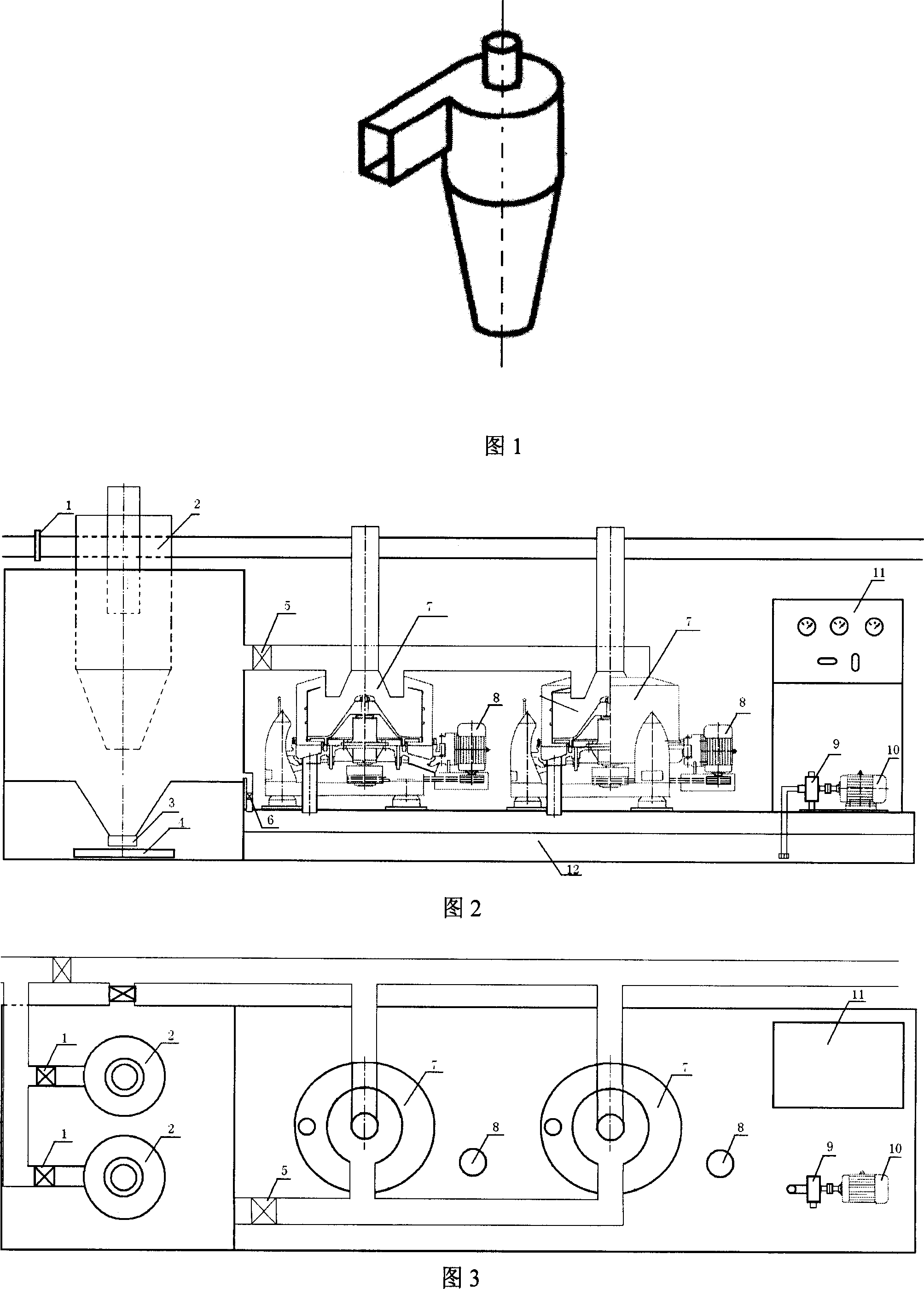

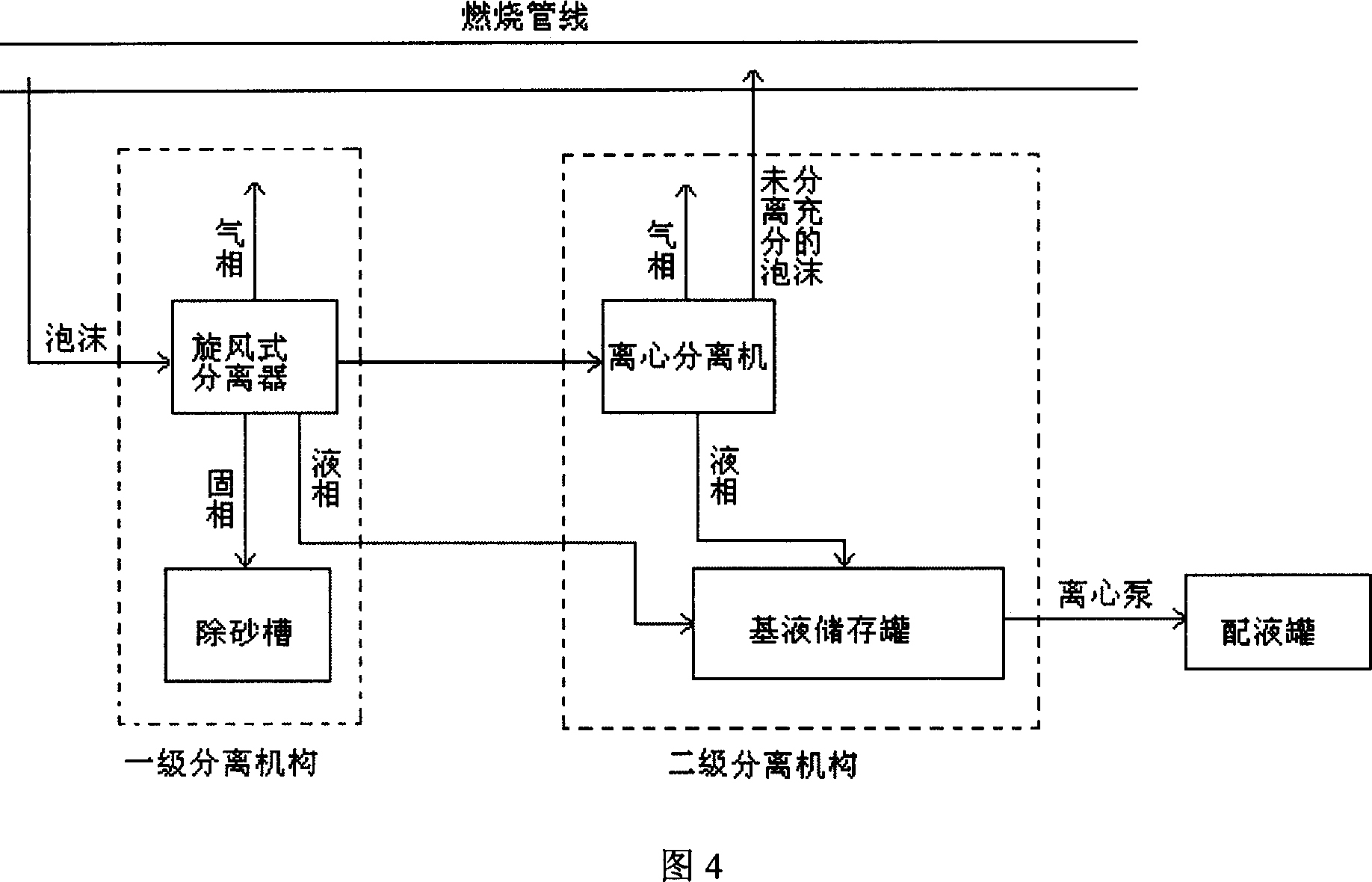

[0014] As shown in Figure 1, Figure 2, Figure 3 and Figure 4, (a) the foam circulated in the wellbore enters the primary separation mechanism through the throttle valve 1 at the inlet of the cyclone separator 2 in Figure 1, and first passes through the cyclone Type separator 2 performs one-stage defoaming. Under the action of centrifugal force, the solid phase particles carried in the foam move toward the outer wall, and at the same time, the gas phase and liquid phase in the foam are separated, and the solid phase particles gradually settle to the cyclone separation under the action of gravity. The combustion outlet 3 at the lower part of the device 2, and finally settle in the sand removal tank 4, the gas phase is discharged from the exhaust port on the top of the cyclone separator, and the separated base liquid enters the base liquid storage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com