Sensor for self-testing self-oscillation of resonant-type tiny cantilever beam

A micro-cantilever beam and self-excited oscillation technology, which is applied to the related MEMS micro-cantilever beam self-excited oscillation self-detection resonant frequency, MEMS micro-cantilever beam sensor field, can solve the problem of increasing system loss, increasing process flow, increasing sensor difficulty and Cost and other issues, to achieve the effect of excellent performance and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

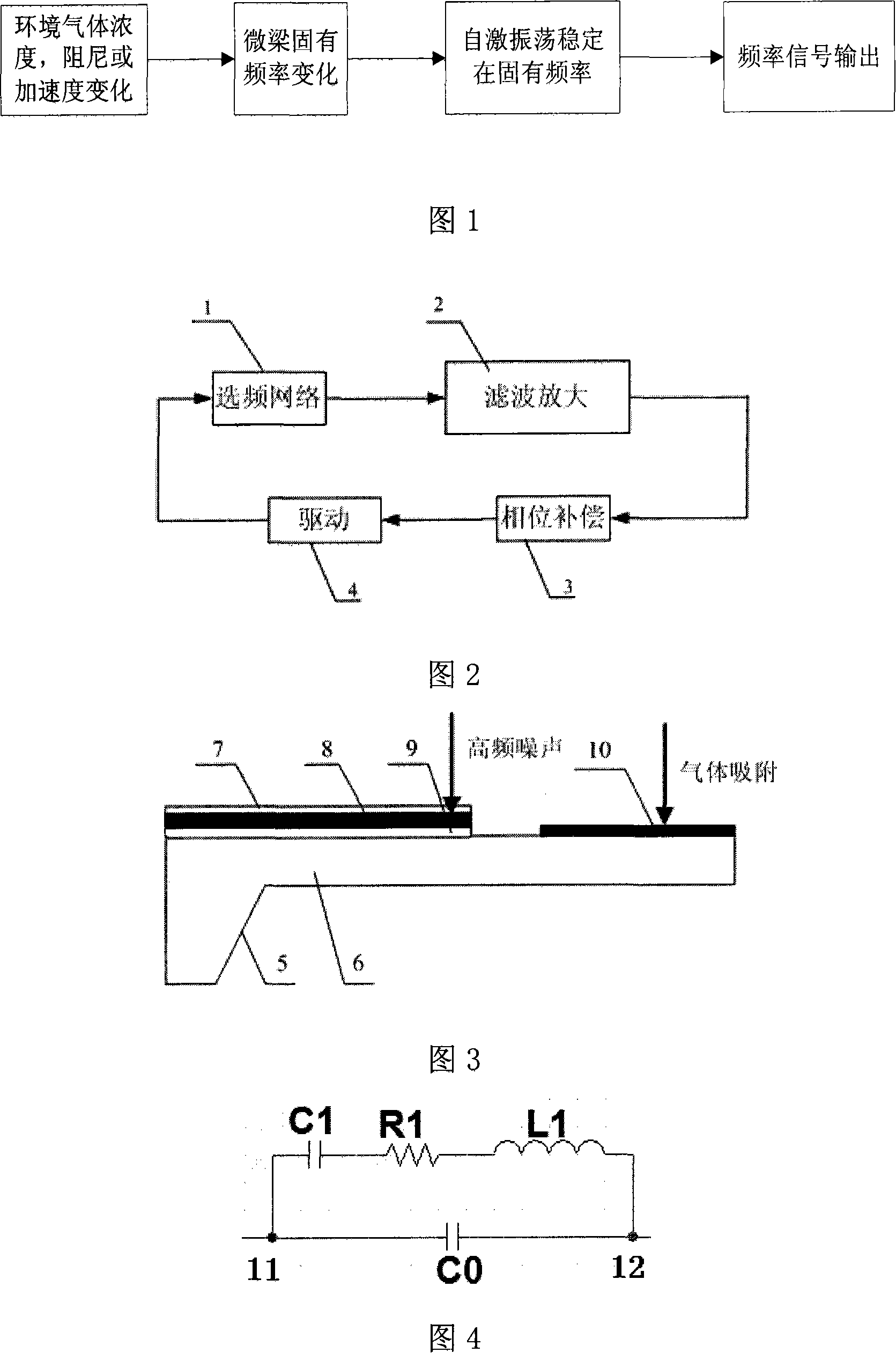

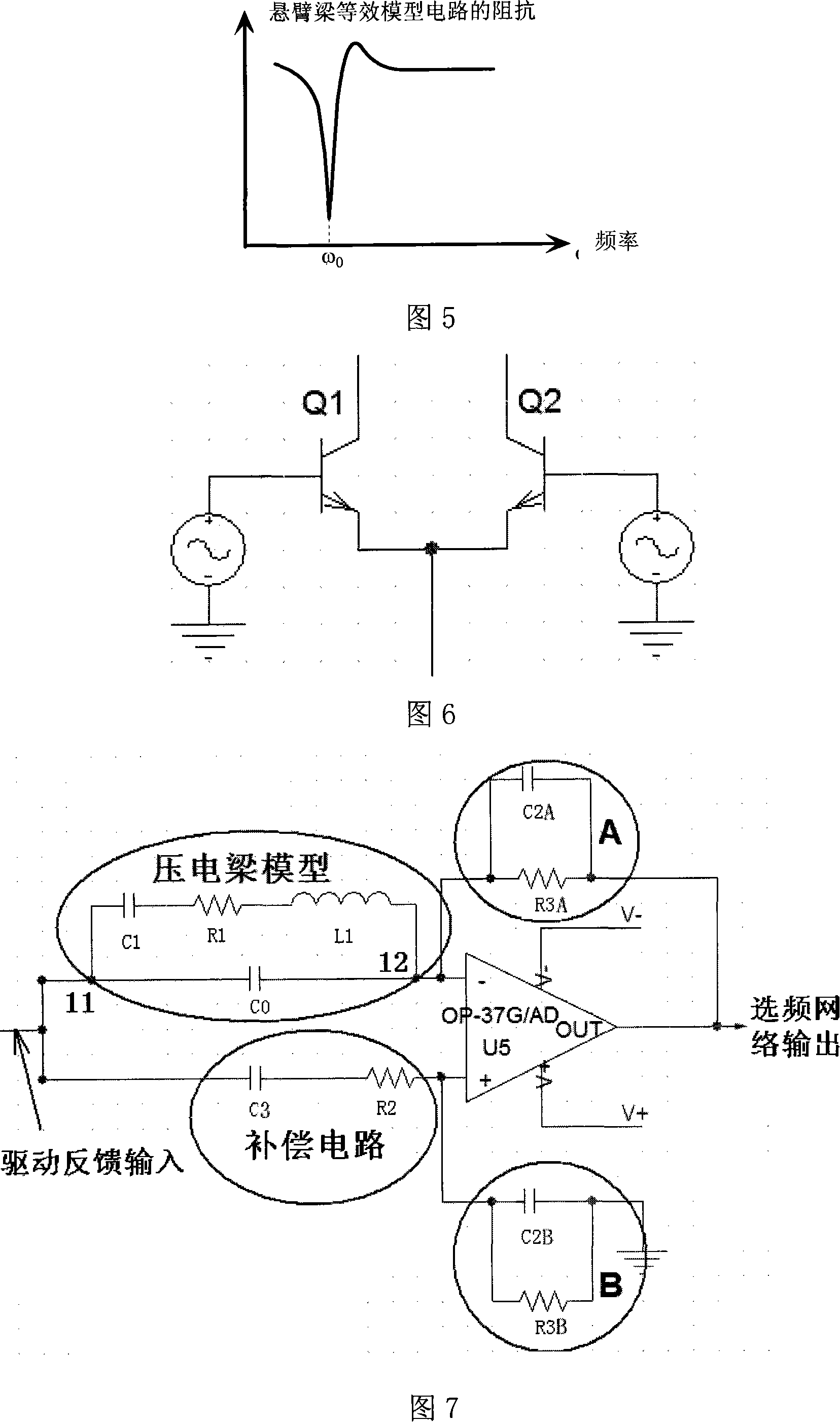

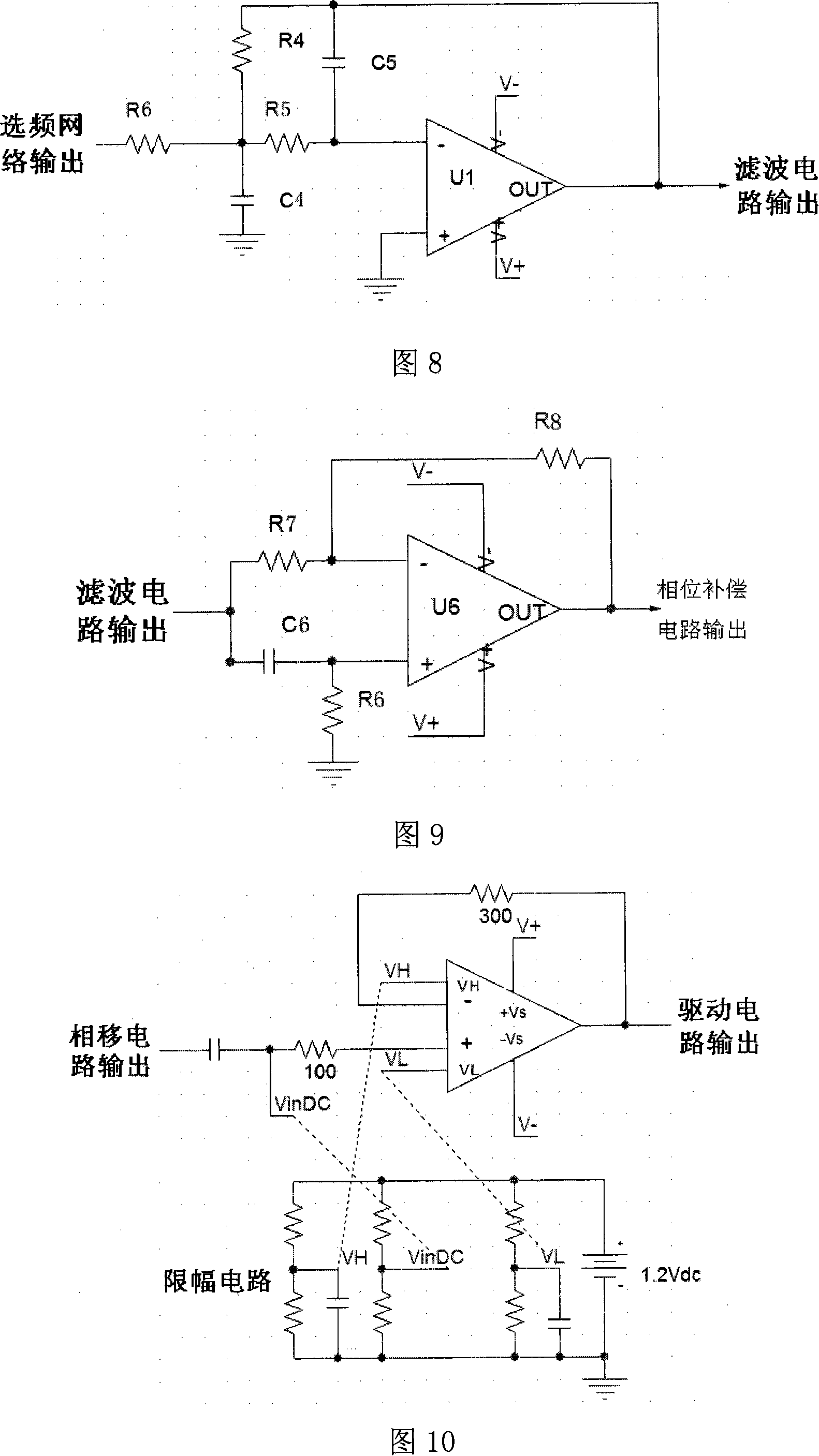

[0032] A resonant MEMS micro-cantilever beam self-excited oscillation self-detection sensor is composed of a MEMS resonant structure and a corresponding closed-loop self-excited oscillation circuit. The MEMS resonant structure is a micro cantilever beam with only one set of self-excited oscillation self-detection structure. The micro-cantilever beam is a sensitive structure for the sensor to perceive changes in the external environment, and its function is to convert measured physical or chemical quantities in the environment, such as gas molecules, environmental damping, acceleration, etc., into frequency variations. The closed-loop self-excited oscillation circuit is characterized by comprising: a differential mode compensation network, a filter circuit, an amplifier circuit, a phase shift circuit and a drive limiter circuit.

[0033]When the closed-loop self-excited oscillating circuit is working, there will be some noise signals in the environment after the entire system i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com