Hot dip coating zinc alloy in use for zinc plating narrow steel strip, method, and ingot mold of zinc alloy

A technology for hot-dip galvanizing and alloying, which is applied in the fields of hot-dip galvanizing alloy, hot-dip galvanizing method and zinc alloy ingot type, can solve the problems of temperature fluctuation of zinc bath, small production capacity, small equipment volume, etc. Fluidity, the effect of reducing the slag rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

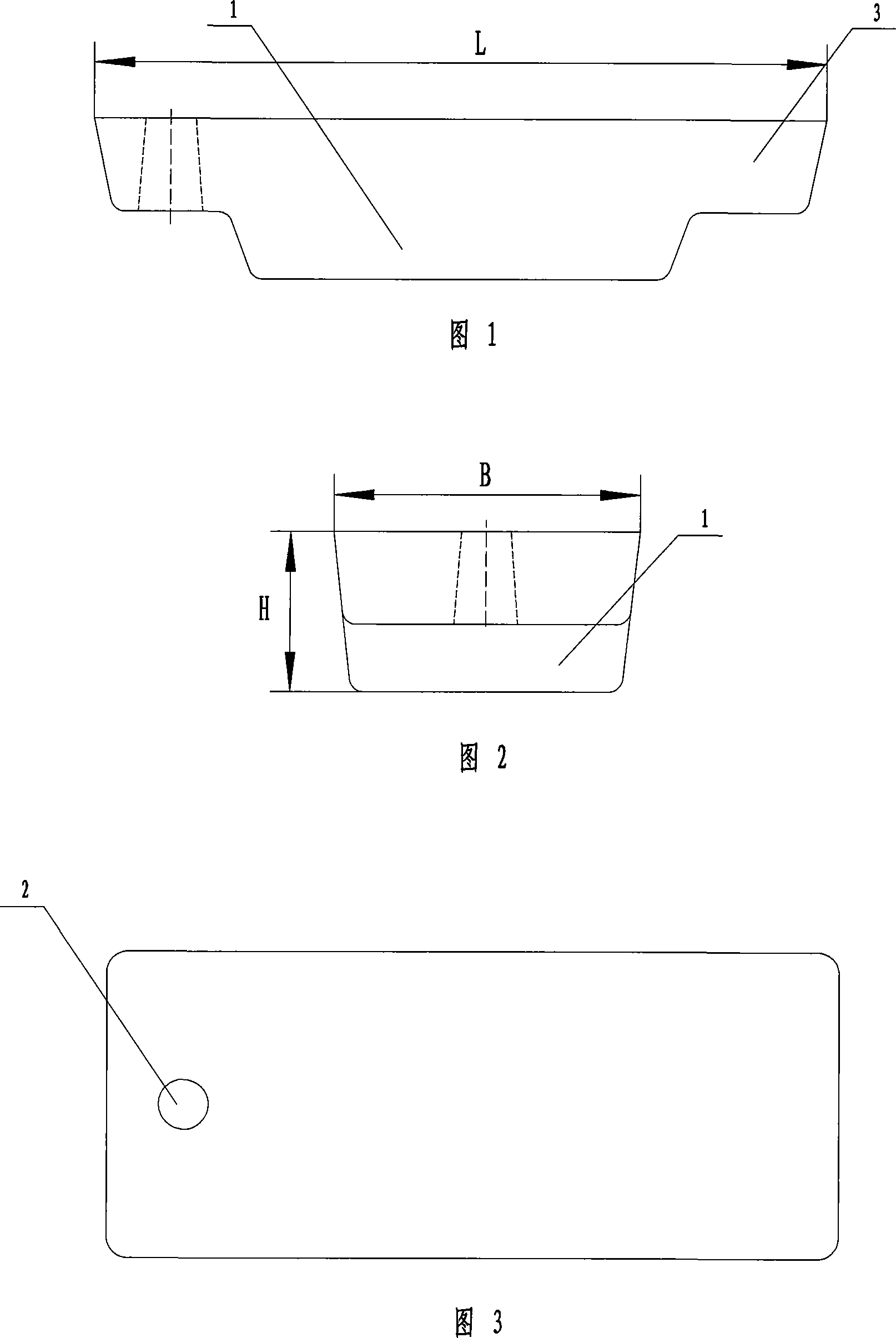

[0029] A hot-dip galvanized alloy for narrow strip galvanizing. The material of the narrow strip steel is Q195. The zinc alloy composition and its weight percentage are: 0.4% (wt) Al, 0.003% (wt) Pb, the rest is zinc and unavoidable of impurities. The shape of the ingot is a "T" shaped cuboid with two symmetrical ears. The bottom of the cuboid is flat. There are hoisting holes on the ears. The four sides are sloped to make the cuboid look big up and down. The weight of the ingot is 530kg. , the ingot length L is 1015mm, the width B is 430mm, and the height H is 230mm.

[0030] The above alloys are directly melted into a zinc bath, and the narrow strip steel made of Q195 is hot-dip galvanized to produce zinc-free plates.

Embodiment 2

[0032]A hot-dip galvanized alloy for narrow strip galvanizing. The material of the narrow strip steel is Q195. The zinc alloy composition and its weight percentage are: 0.5% (wt) Al, 0.003% (wt) Pb, the rest is zinc and unavoidable of impurities. The ingot shape is a "T"-shaped cuboid with two symmetrical ears. The bottom of the cuboid is flat, and the ears are provided with hoisting holes. The four sides are sloped to make the cuboid appear large up and down. The weight of the ingot is 430kg. , the ingot length L is 985mm, the width B is 410mm, and the height H is 210mm.

[0033] The above alloys are directly melted into a zinc bath, and the narrow strip steel made of Q195 is hot-dip galvanized to produce zinc-free plates.

Embodiment 3

[0035] A hot-dip galvanized alloy for narrow-band galvanizing, the zinc alloy composition and its weight percentage are: 0.5% (wt) Al, 0.003% (wt) Pb, the rest is zinc and unavoidable impurities. The shape of the ingot is a "T" shaped cuboid with two symmetrical ears. The bottom of the cuboid is flat. There are hoisting holes on the ears. The four sides are sloped to make the cuboid look big up and down. The weight of the ingot is 530kg. , the ingot length L is 1015mm, the width B is 430mm, and the height H is 230mm.

[0036] The above alloys are directly melted into a zinc bath, and the narrow strip steel made of Q195 is hot-dip galvanized to produce zinc-free plates.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com