Method for extracting pyrified isomerase of linoleic acid from strain of producing isomerase of linoleic acid

A technology for linoleic acid isomerase and purification of linoleic acid, applied in the directions of isomerase, fermentation, etc., can solve the problems of toxic solvents, complex isomer composition, complicated extraction and purification process, etc. The effect of reducing enzyme activity loss and high cell fragmentation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

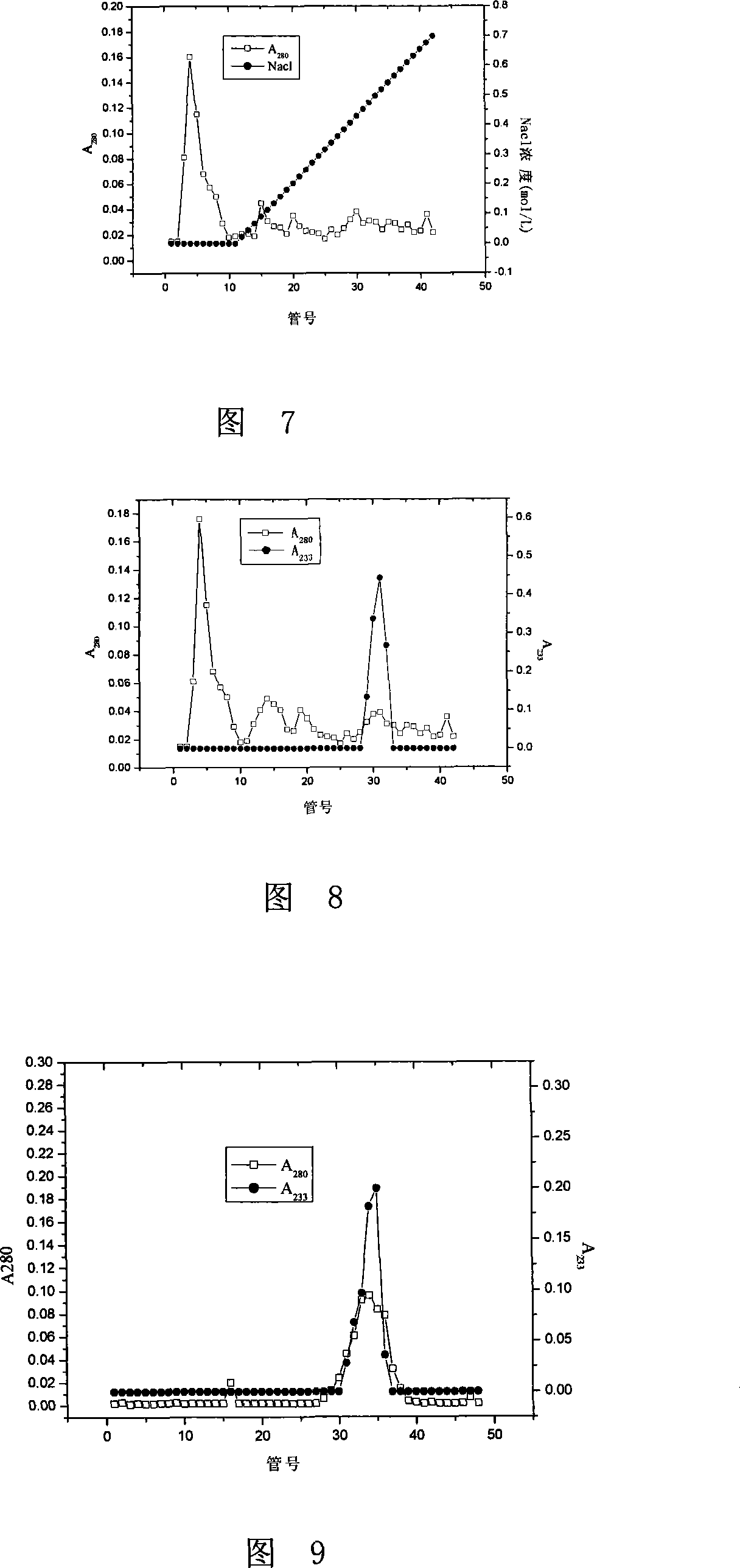

[0039] Embodiment 1, extraction and purification of linoleic acid isomerase

[0040] 1. Obtaining of linoleic acid isomerase fermentation broth

[0041] The fermentation medium used in this embodiment is prepared according to the following method:

[0042] (1) Preparation of sunflower seed oil emulsion: 300mg of sunflower seed oil (Shanghai Jiage Food Co., Ltd., Duoli brand 100% pure sunflower seed oil), 0.36ml of Tween-80 (Tween-80), 5ml of deionized water , ultrasonic emulsification (25° C., ultrasonic frequency 40 KHz) for 10 min, and filter sterilization with a 0.22 μm microporous membrane to obtain a sunflower oil emulsion.

[0043] (2) Preparation of skim milk medium: 12 g of skim milk powder (Sanyuan Dairy Co., Ltd.) was dissolved in 100 ml of water, and sterilized at 5° C. for 10 minutes for later use.

[0044](3) Preparation of fermentation medium: the sunflower oil emulsion of (1) was added to the skim milk medium of (2), so that the final concentration of sunflowe...

Embodiment 2

[0058] Embodiment 2, extraction and purification of linoleic acid isomerase

[0059] 1. Obtaining of linoleic acid isomerase fermentation broth

[0060] The fermentation medium used in this embodiment is prepared according to the following method:

[0061] The fermentation medium used in this embodiment is prepared according to the following method:

[0062] (1) Preparation of sunflower seed oil emulsion: 400 mg of sunflower oil (Shanghai Jiage Food Co., Ltd., Duoli brand 100% pure sunflower oil), Tween-80 (Tweenum 80) 0.44 ml, deionized water 5 ml, Ultrasonic emulsification (25° C., ultrasonic frequency 40 KHz) for 10 minutes, and filter sterilization with a 0.22 μm microporous membrane to obtain sunflower oil emulsion.

[0063] (2) Preparation of skim milk medium: 12 g of skim milk powder (provided by Beijing Sanyuan Dairy Co., Ltd.) was dissolved in 100 ml of water, and sterilized at 5° C. for 10 minutes for later use.

[0064] (3) Preparation of fermentation medium: the...

Embodiment 3

[0078] Embodiment 3, extract and purify linoleic acid isomerase

[0079] 1. Obtaining of linoleic acid isomerase fermentation broth

[0080] The fermentation medium used in this embodiment is prepared according to the following method:

[0081](1) Preparation of sunflower seed oil emulsion: 600mg of sunflower seed oil (Shanghai Jiage Food Co., Ltd., Duoli brand 100% pure sunflower seed oil), 0.5ml of Tween-80 (Tween-80), 5ml of deionized water , ultrasonic emulsification (25° C., ultrasonic frequency 40 KHz) for 10 min, and filter sterilization with a 0.22 μm microporous membrane to obtain a sunflower oil emulsion.

[0082] (2) Preparation of skim milk medium: 12 g of skim milk powder (Sanyuan Dairy Co., Ltd.) was dissolved in 100 ml of water, and sterilized at 115° C. for 10 minutes for later use.

[0083] (3) Preparation of fermentation medium: the sunflower oil emulsion of (1) was added to the skim milk medium of (2), so that the final concentration of sunflower oil was 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com