Vertical shaft support system of vertical shaft type impact crusher, and vertical shaft support device

A technology of impact crusher and supporting device, which is applied in the direction of shafts, bearings, rigid supports of bearing components, bearings, etc., which can solve the problems of high cleanliness requirements of lubricating oil, uncertain load direction, poor working environment, etc., and achieve high crushing efficiency. Ratio and production capacity, meet the speed requirements, improve the effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

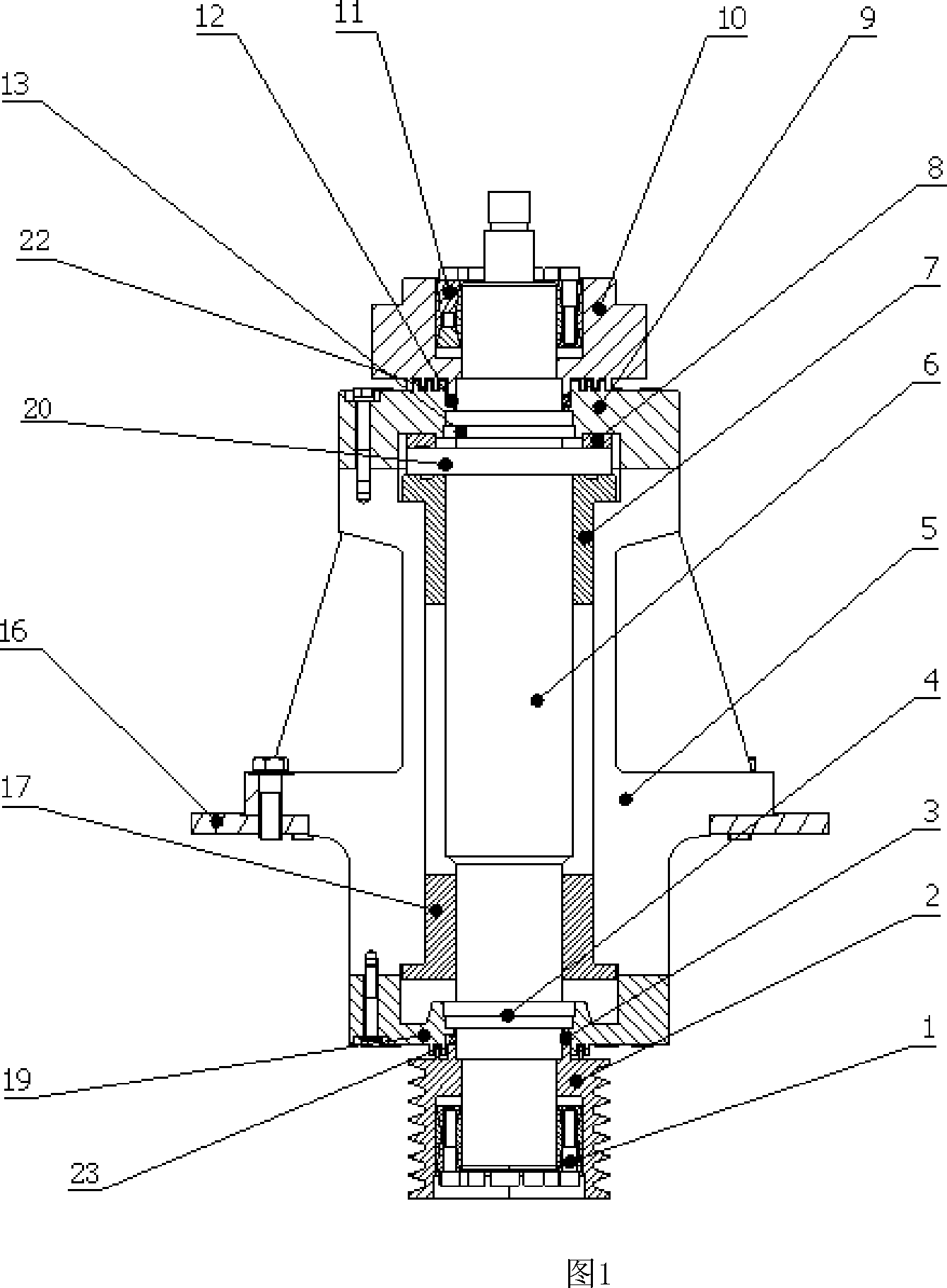

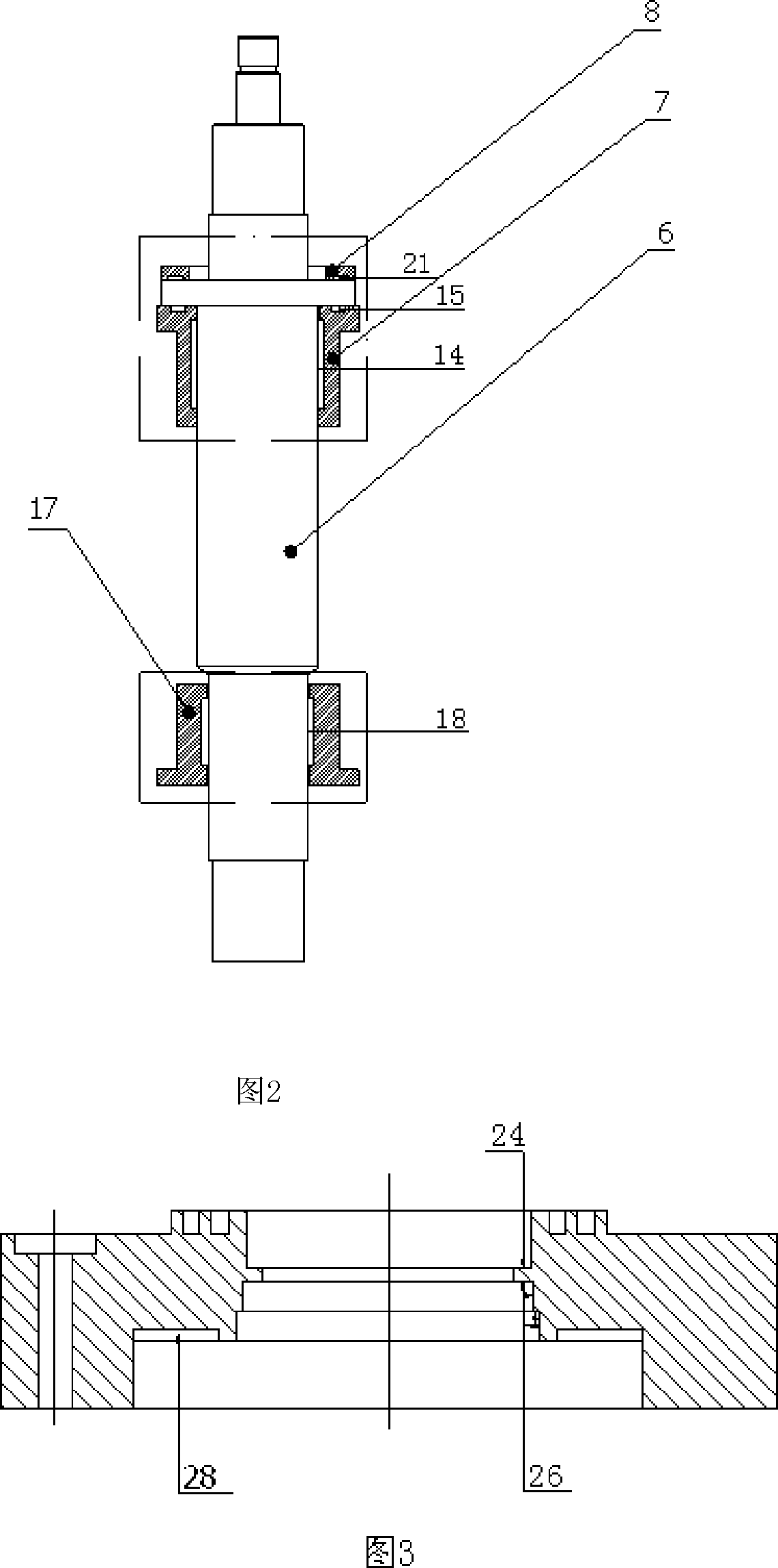

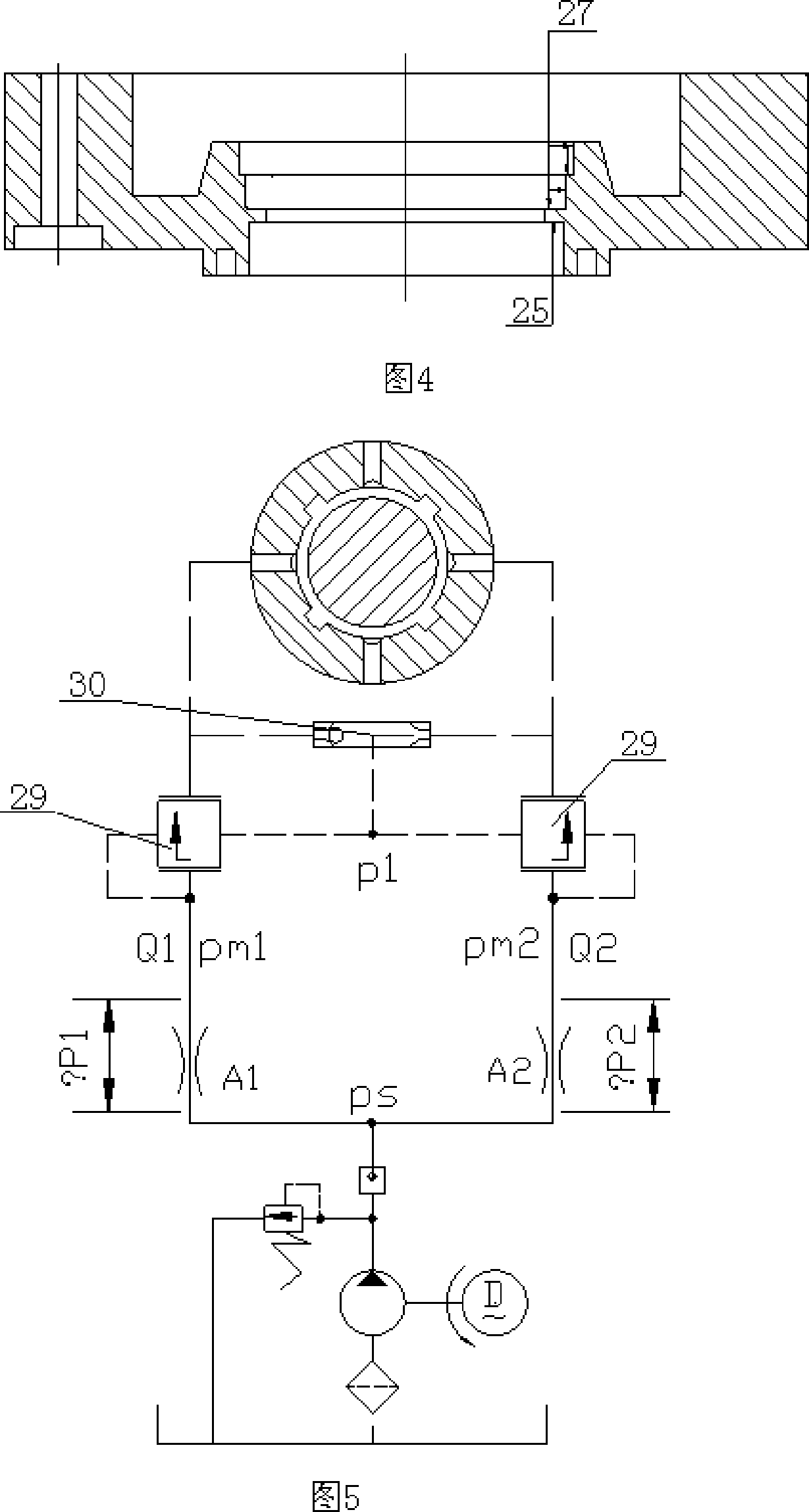

[0027] Embodiment: A vertical shaft support system for a vertical shaft impact crusher, comprising a vertical shaft support box, a vertical shaft is arranged on the vertical shaft support box, and an upper end cover and a lower end are respectively connected to the upper end and the lower end of the vertical shaft support box Cover; the hydrostatic bearing supporting the vertical shaft is installed in the bearing seat of the vertical shaft supporting seat box and the upper end cover; the performance of the vertical shaft is improved by utilizing the characteristics that the speed of the hydrostatic bearing has nothing to do with the load and the characteristics of resistance to shock and vibration Support conditions, thereby greatly improving the rotor speed, bearing life and adaptability to continuous random vibration of the vertical shaft impact crusher. The oil supply system of the hydrostatic bearing installed at the same time is a stable flow oil supply system.

[0028] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com