Method for forming tantalum nitride film

A technology of nitride film and film forming chamber, which is applied in the direction of gaseous chemical plating, coating, electrical components, etc., can solve problems such as film difficulties, and achieve good adhesion and smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

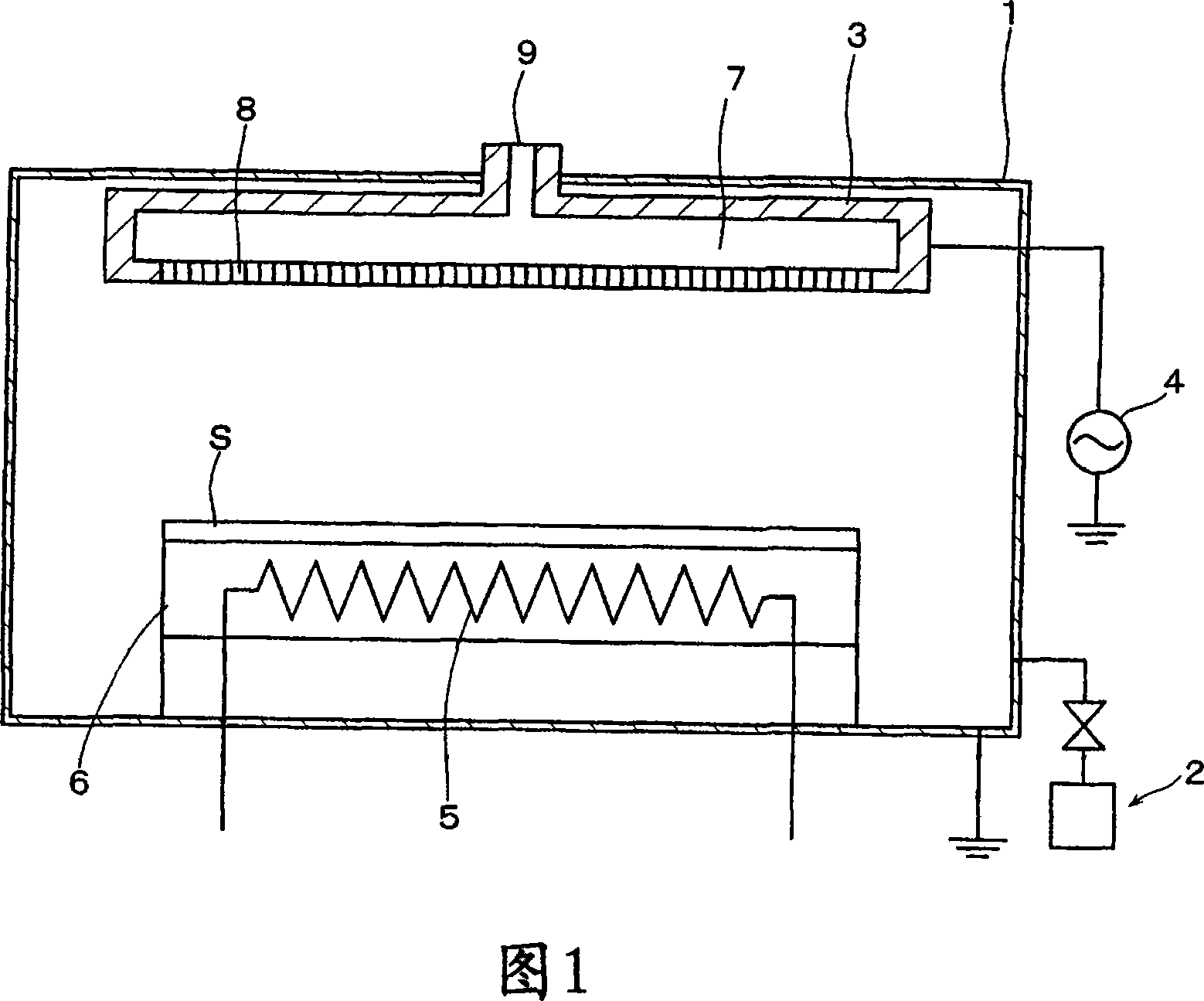

[0064] In this example, using the film forming apparatus 1 shown in FIG. 3 gas to form a tantalum nitride film.

[0065] According to known methods, in the implementation with SiO 2 After the degassing pretreatment process on the surface of the substrate S of the insulating film, the substrate S is moved into the vacuum exhaust system 2 to 10 -5 In the vacuum chamber 1 below Pa. The substrate is not particularly limited, and for example, a substrate in which plasma is generated by applying a voltage to a target mainly composed of Ta using Ar sputtering gas according to a common sputtering film formation method can also be used. , a sputtering target, a substrate on which a substrate-side adhesive layer is formed on the surface.

[0066] The substrate S is loaded into the vacuum chamber 1, and after the substrate S is placed on the substrate mounting table 6, the substrate is heated to 250° C. with the heater 5, and the gas introduction system 9 is introduced into the gas ch...

Embodiment 2

[0078] In this example, the tantalum nitride film obtained in Example 1 was implanted with tantalum particles by sputtering using a known sputtering device to form a tantalum nitride film further enriched in tantalum.

[0079] Ar sputtering gas is introduced into the sputtering device, a voltage is applied to the target from the voltage applying device to discharge, plasma is generated, and the target mainly composed of tantalum is sputtered, and incident on the thin film formed on the substrate S as sputtering. Tantalum particles that shoot particles. The sputtering conditions are DC power: 5kW, RF power: 600W. In addition, the sputtering temperature is -30 to 150°C.

[0080] The content of tantalum in the barrier film can be further increased by sputtering with implanted tantalum particles, and a desired low-resistance tantalum-rich tantalum nitride film can be obtained. In addition, by injecting tantalum into the surface thin film of the substrate S, the decomposition of ...

Embodiment 3

[0084] In addition to using t-amyliminotris(dimethylamino)tantalum instead of penta(dimethylamino)tantalum as the raw material gas, when the film-forming process was carried out according to Example 1, a tantalum-rich low Resistor with tantalum nitride film. For the obtained film, Ta / N=1.8, C content: 3%, N content: 35.7%, and resistivity 550 μΩ·cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com