Energy absorber of filling deformed foam aluminium and aluminium alloy

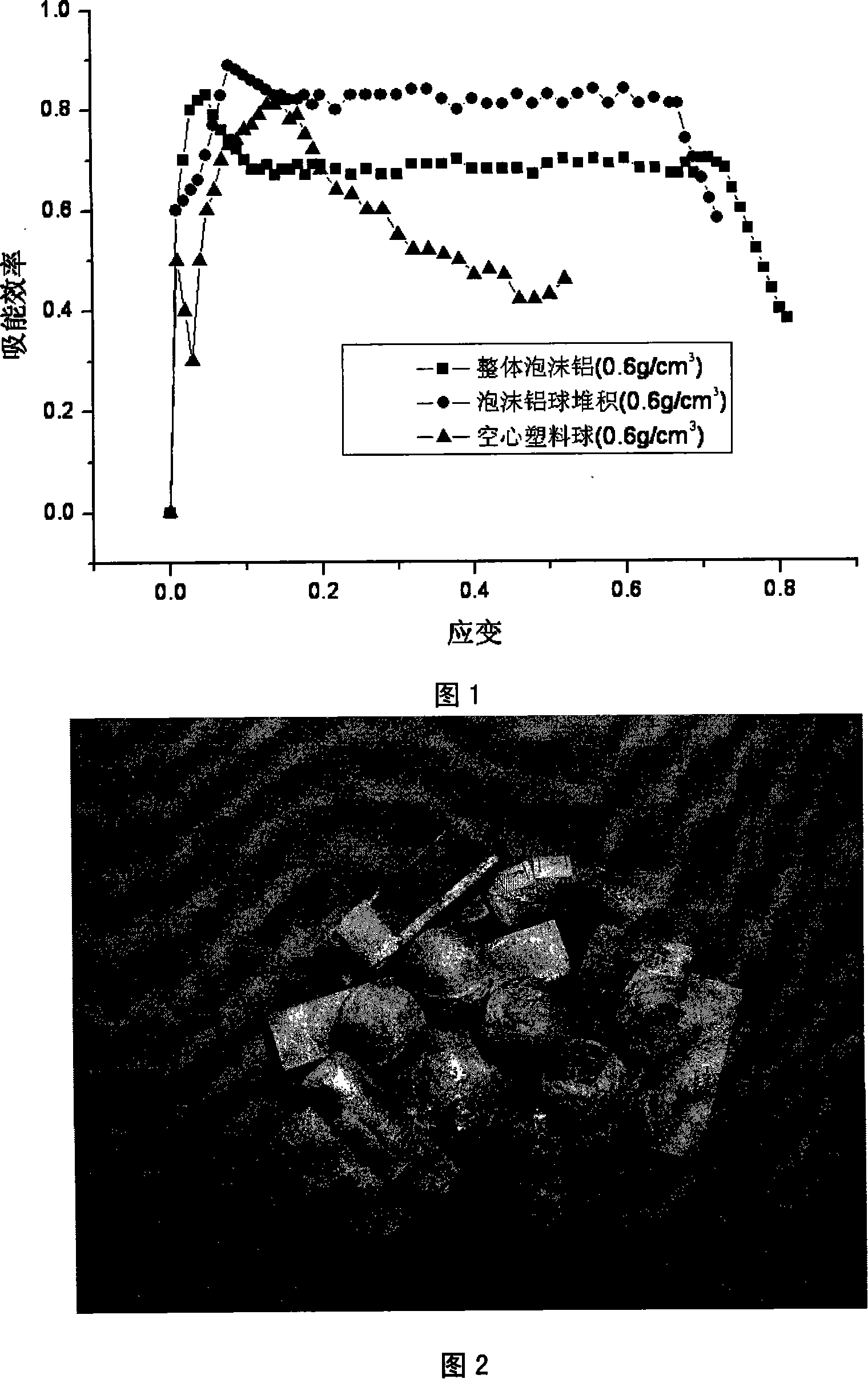

An energy absorber, aluminum alloy technology, applied in the direction of friction shock absorber, can solve the problems of reduced energy absorption effect, personnel injury, low applicability of special-shaped structure, etc., to achieve light weight, high energy absorption rate, good energy absorption effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

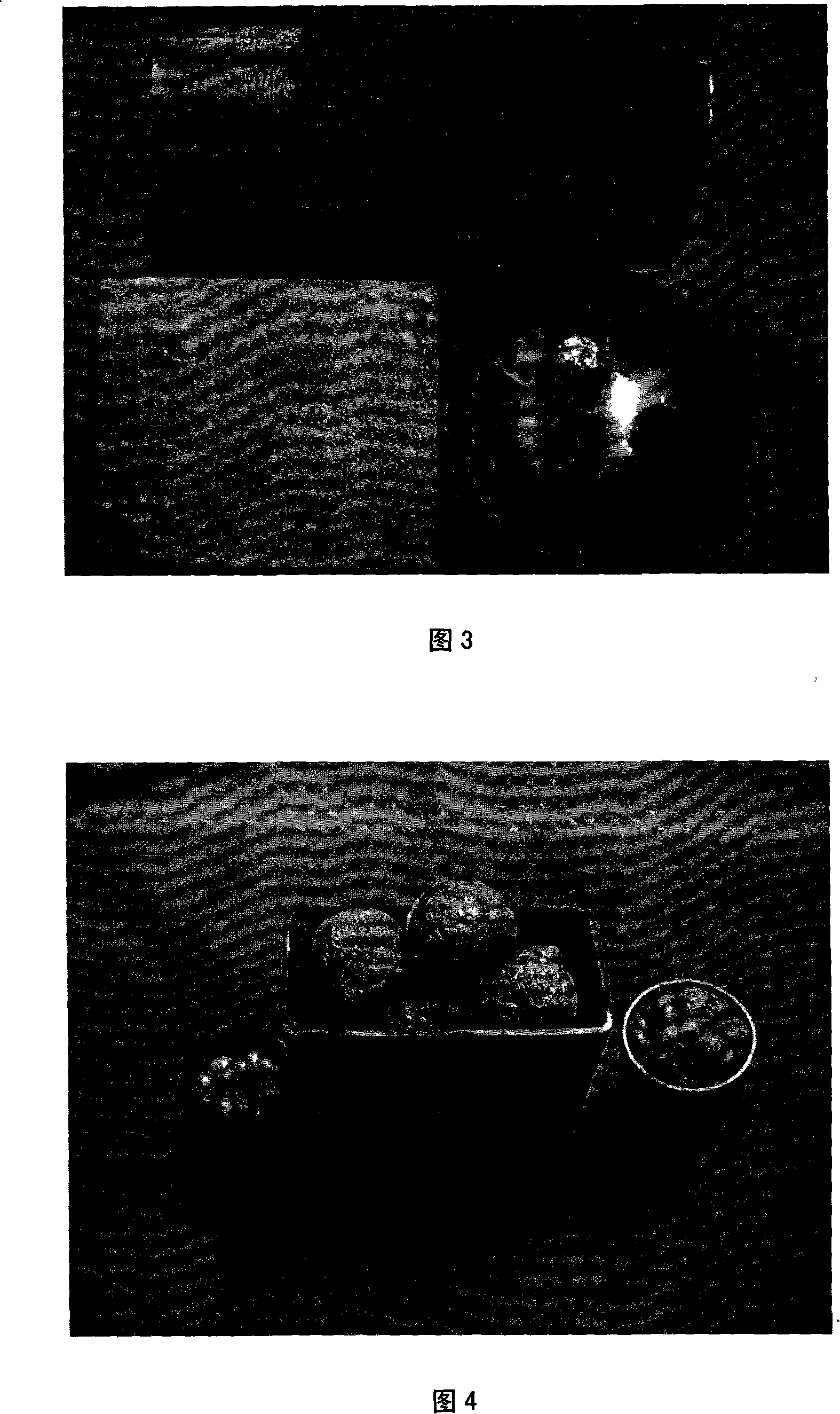

[0017] The first step: first, through the secondary foaming method, prepare a foamed aluminum alloy spherical piece with a porosity of 83.8%, an average pore diameter of 1.7mm, and an average diameter of 12mm to obtain a filler;

[0018] The second step: use an aluminum tube with a thickness of 3mm and a diameter of 10mm as the shell, and complete the accumulation of the secondary foamed aluminum alloy filling parts in the shell, and the stacking density is 73.5%;

[0019] Step 3: Seal the foam filler in the aluminum tube by welding to make a special-shaped energy absorber.

[0020] Step 4: Carry out anti-corrosion treatment on the special-shaped energy absorber.

Embodiment 2

[0022] The first step: firstly, through the secondary foaming method, a foamed aluminum alloy spherical piece with a porosity of 75.8%, an average pore diameter of 1.7mm, and an average diameter of 23mm is prepared to obtain a filler;

[0023] The second step: use a stainless steel right-angle elbow with a thickness of 2mm and a diameter of 90mm as the shell, and complete the accumulation of the secondary foamed aluminum alloy filling parts in the shell, and the stacking density is 65.3%;

[0024] Step 3: Seal the foam filler in the stainless steel right-angle elbow by welding to make a special-shaped energy absorber.

[0025] Step 4: Carry out anti-corrosion treatment on the special-shaped energy absorber.

Embodiment 3

[0027] The first step: firstly, through the secondary foaming method, a foamed aluminum alloy spherical piece with a porosity of 50.4%, an average pore diameter of 1.0mm, and an average diameter of 23mm is prepared to obtain a filler;

[0028] The second step: use a stainless steel right-angle elbow with a thickness of 2mm and a diameter of 90mm as the shell, and complete the accumulation of the secondary foamed aluminum alloy filling parts in the shell, and the stacking density is 30.0%;

[0029] Step 3: Seal the foam filler in the stainless steel right-angle elbow by welding to make a special-shaped energy absorber.

[0030] Step 4: Carry out anti-corrosion treatment on the special-shaped energy absorber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com