Wire rod excellent in wire-drawing workability and method for producing same

A manufacturing method and technology for wire rods, which are applied in manufacturing tools, temperature control, heat treatment process control, etc., can solve problems such as ductility deterioration of wire drawing products and reduction of mold life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

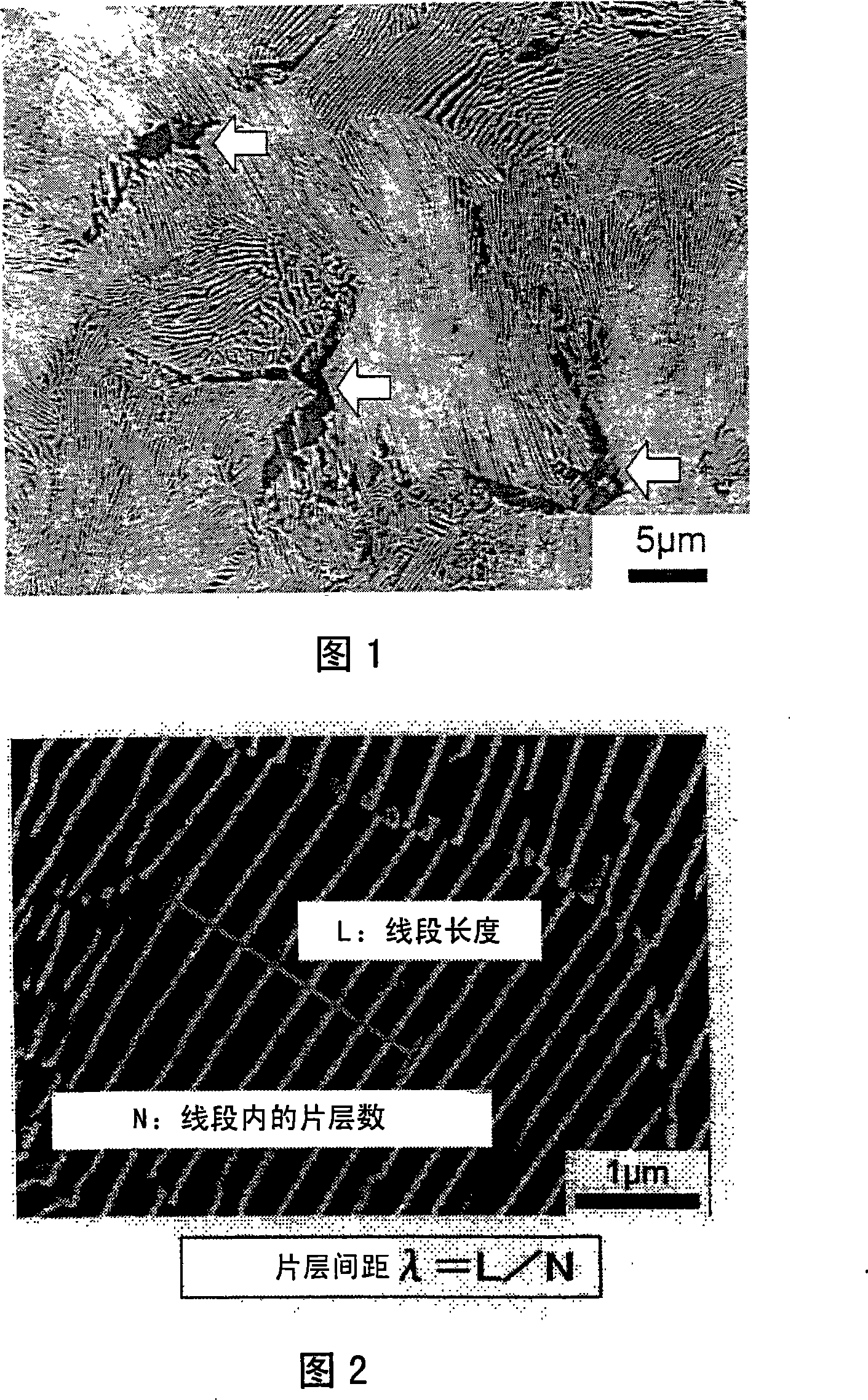

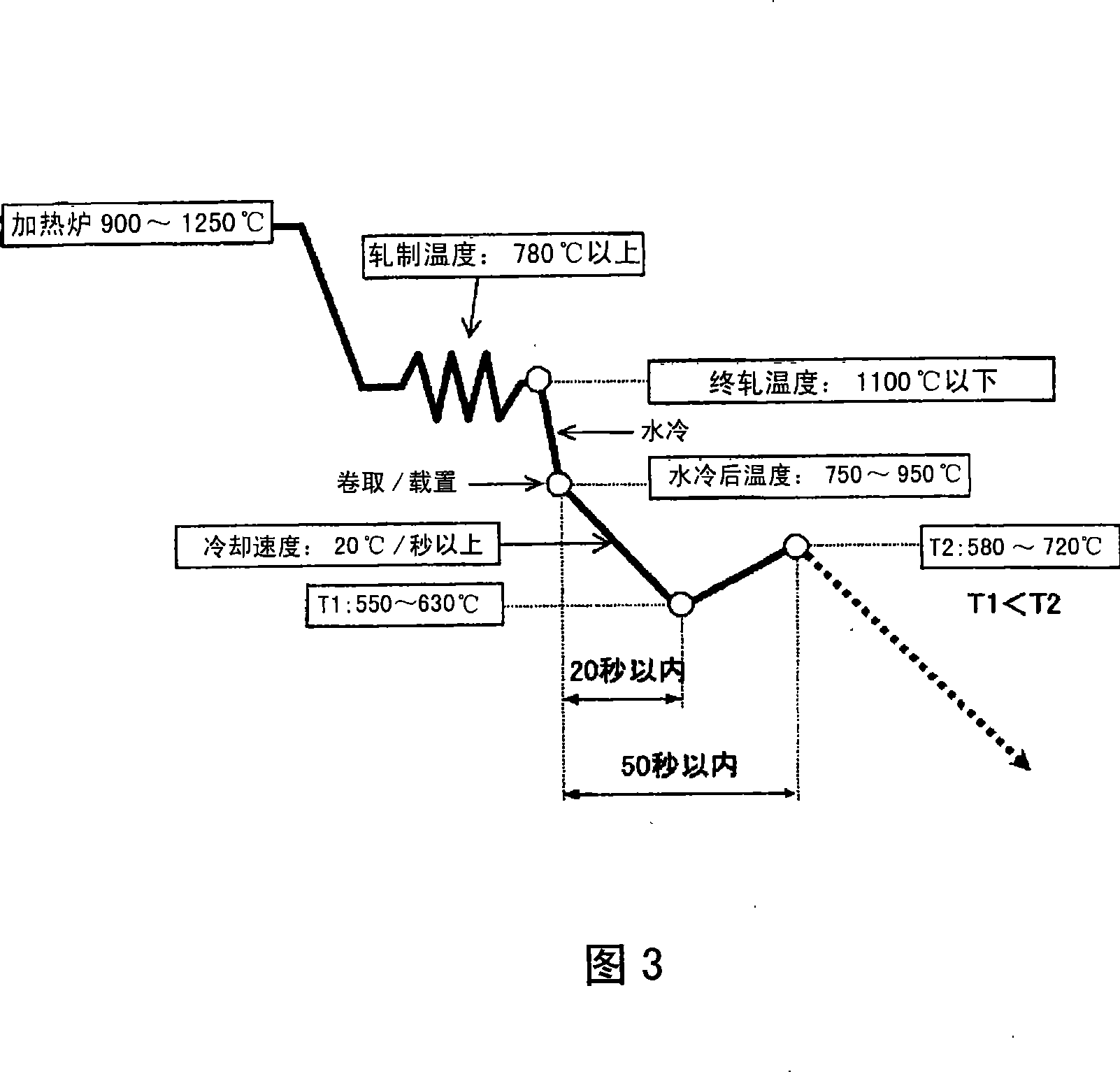

[0021] The wire rod of the present invention has characteristics in its compositional requirements and structural requirements (the area ratio of the second phase ferrite and the interlamellar spacing of pearlite). Therefore, first, the components of the wire rod (steel material) will be described.

[0022] C: 0.6 to 1.1% (mass % means the same below)

[0023] C is an element that affects the strength of the wire rod, and it is necessary to add 0.6% or more in order to ensure the necessary strength of the steel cords, tire steel wires, PC steel wires, etc. that are the object of the present invention. On the other hand, if the amount of C is too large, the ductility will deteriorate, so the upper limit is made 1.1%. The amount of C is preferably not less than 0.8% and not more than 1.0%.

[0024] Si: 0.1 to 2.0%

[0025] In wire rods that are highly wire-drawn, Si is added especially for the purpose of deoxidation, and it is necessary to add 0.1% or more. In addition, Si a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com