Potato slicer

A potato and slicer technology, which is applied in metal processing and other directions, can solve the problems of perishable deterioration of potato chips and potato residues, and easy residual potato slices, etc., and achieves the effect of small size and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

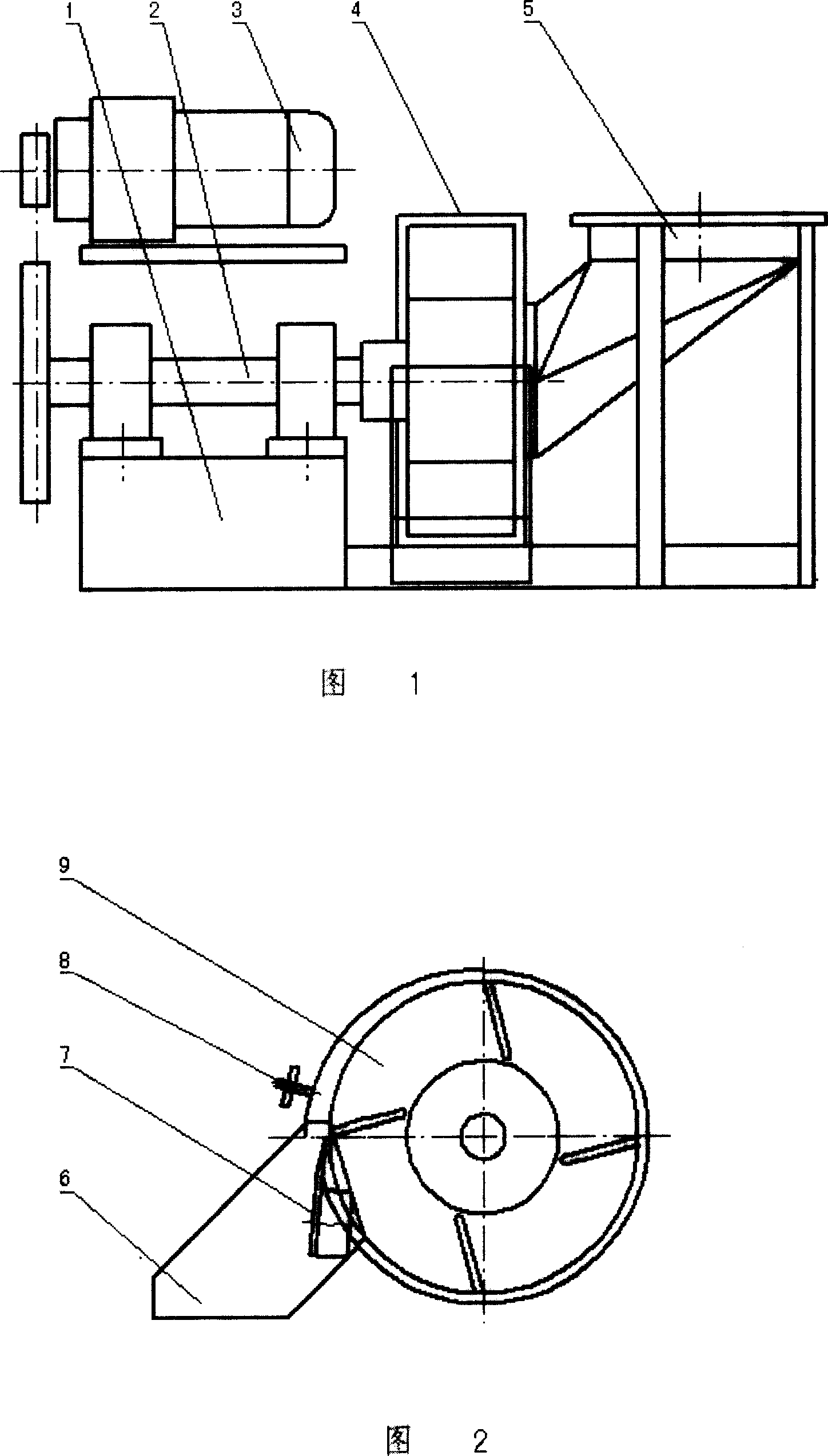

[0015] Embodiment 1 The potato slicer that the present invention implements is used on the whole potato powder production line: the potatoes that are processed through the sorting process fall into the feeding device (5) that is installed on one end of the frame (1) in an orderly manner. The guide of the device (5) enters from the axial direction into the central part of the rotor (9) fixed on the rotor shaft (2) by fasteners, and the horizontally installed rotor shaft (2) is installed on the other end of the frame (1) Driven by the transmission device (3), the potato rotates rapidly with the rotor (9), and under the action of centrifugal force, it moves along the arc plate of the volute (4) at a constant speed. (7) In the relative motion field between the cutting edge and the fast-rotating rotor (9) paddle, the potato is subjected to strong shearing action, and the part attached to the inner wall of the arc-shaped plate of the volute (4) to the cutting edge of the cutting knif...

Embodiment 2

[0016] Example 2 The potato slicer implemented in the present invention can be used in production lines such as sweet potato powder, taro powder, carrot powder, etc., to meet the process requirements for tubers, fruit and vegetable materials such as sweet potatoes, taro, and carrots that have been processed through the sorting process. The slicing works without any slicing residue in the machine.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap