Reflow furnace

A technology of reflow furnace and atmosphere gas, which is applied in the field of reflow furnace of atmosphere purification device, which can solve the problems of heater 115 power consumption, large energy loss, and conflict of energy saving, and achieve the effects of not easy failure, high-efficiency combustion, and shortened lag time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

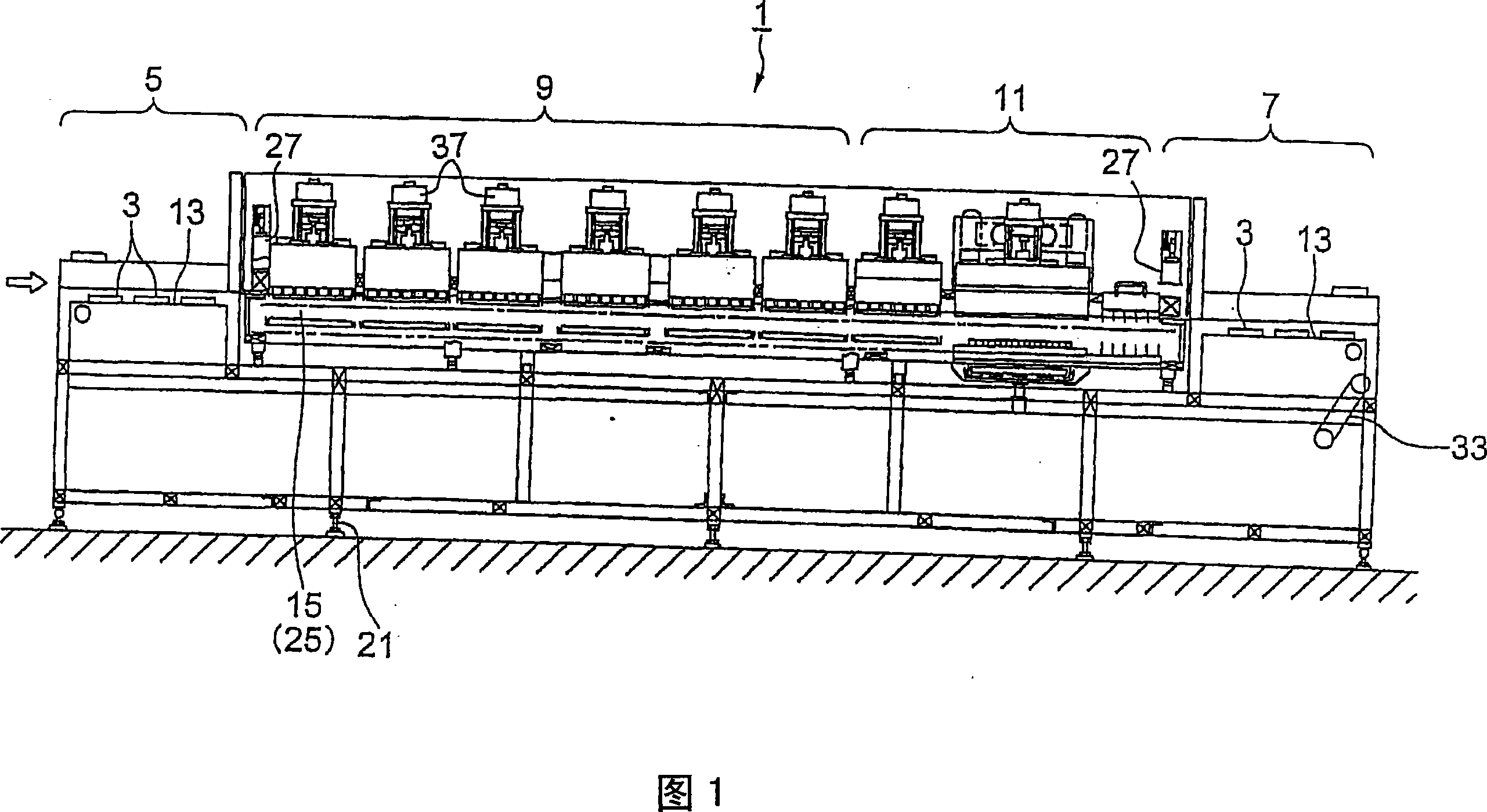

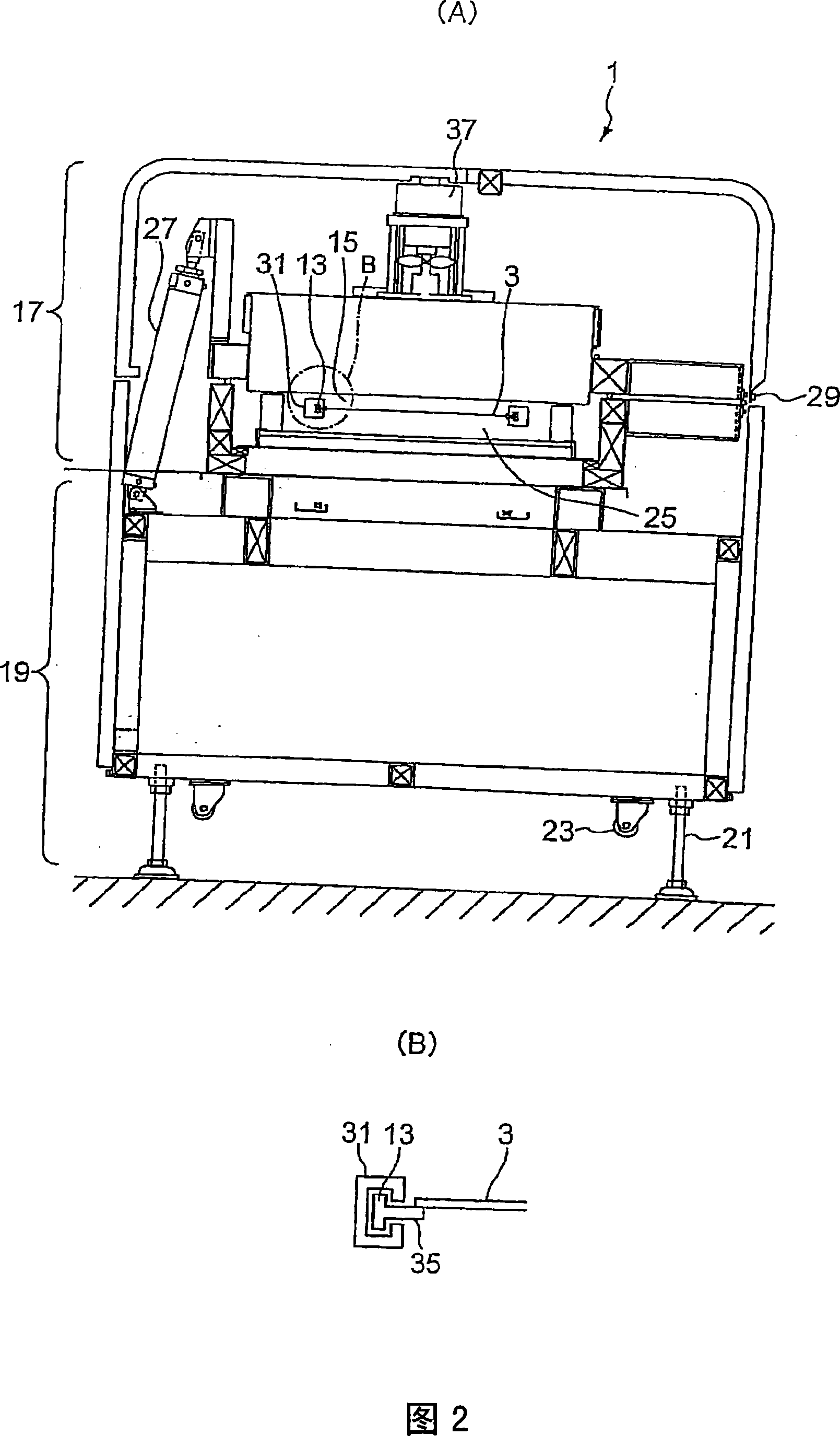

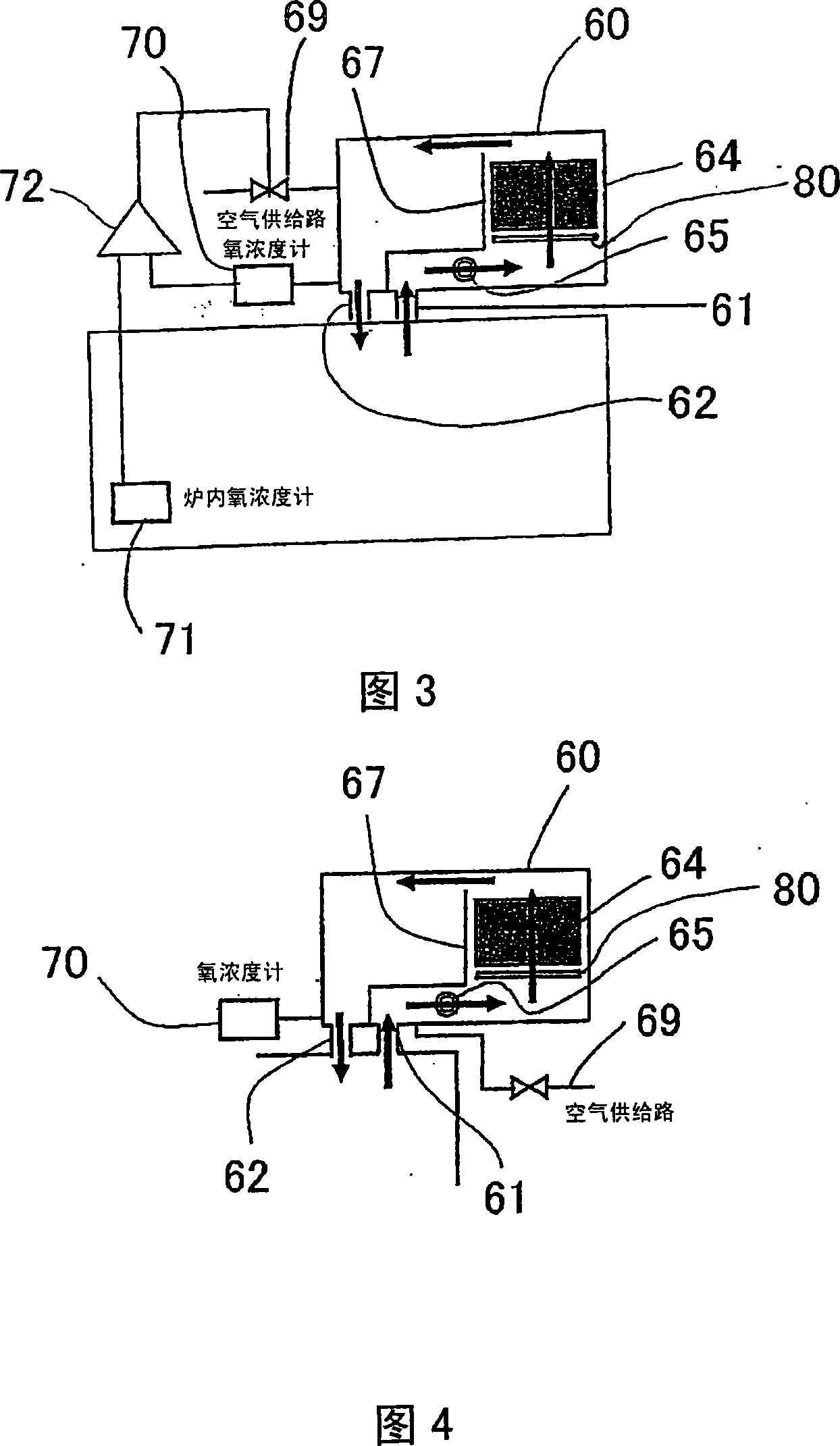

[0088] The reflow furnace of the present invention will be described with reference to the drawings.

[0089] One aspect of the reflow furnace of the present invention is to provide a reflow furnace including: a transport device for transporting a circuit board on which electronic components are mounted; and a heating chamber for transporting the circuit board inside and heating the circuit board through an atmospheric gas to perform soldering. An atmosphere purification device having: a device for extracting a part of the atmosphere gas containing a flux component vaporized in the brazing, a device for heating the extracted atmosphere gas to a desired temperature, and making the heated atmosphere gas An oxidation catalyst for burning the flux components contained in the flux, a device for controlling the oxygen concentration of the high-temperature gas after the combustion treatment, and a device for returning the high-temperature gas with the controlled oxygen concentration a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com