An experimental device suitable for realizing solid-phase oxygen-controlled reaction

An experimental device and reaction technology, which is applied in the direction of various fluid ratio control, etc., can solve the problems of increasing the difficulty of operation, and achieve the effect of simple overall structure design, easy realization and operation, and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

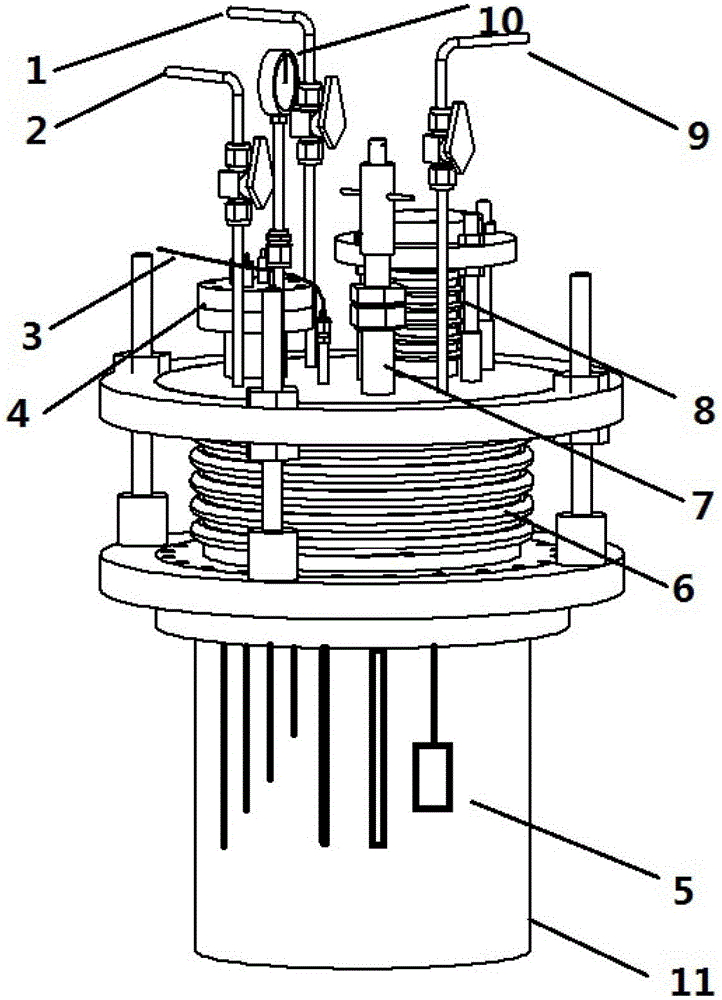

[0016] like figure 1 As shown, the present invention includes an air inlet 1, a vacuum port 2, a thermocouple 3, a multi-point liquid level gauge 4, a mass exchanger 5, a second bellows 6, an oxygen meter 7, a first bellows 8, an outlet Air port 9, barometer 10, tank body 11. First, solid lead-bismuth is loaded into the tank body, and the loading amount is about 4 / 5 of the tank body capacity after melting (can be calculated by parameters such as mass and density); the first bellows 8 and the second bellows 6 After stretching to the maximum length, connect the lower end flange of the second bellows to the tank body 11 and seal it, then vacuumize the device through the vacuum port 2 for about 30 minutes, then close the vacuum port, and fill with 99.999% argon to 0.12MPa , vacuumize again, after repeating 3 times, heat the tank body 11 to melt the solid lead-bismuth; after the lead-bismuth melts, adjust the second bellows 6 downward, and stop adjusting the second bellows 6 after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com