IC detecting machine capable of simultaneously multiple parallel built-in testing

A detection machine and insertion technology, which is applied in the direction of electronic circuit testing, electrical measuring instrument parts, measuring electricity, etc., can solve the problems of limited production capacity, multi-exchange displacement time, and multi-time, so as to reduce IC exchange pick-and-place The effect of shifting time, reducing standby time, and increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

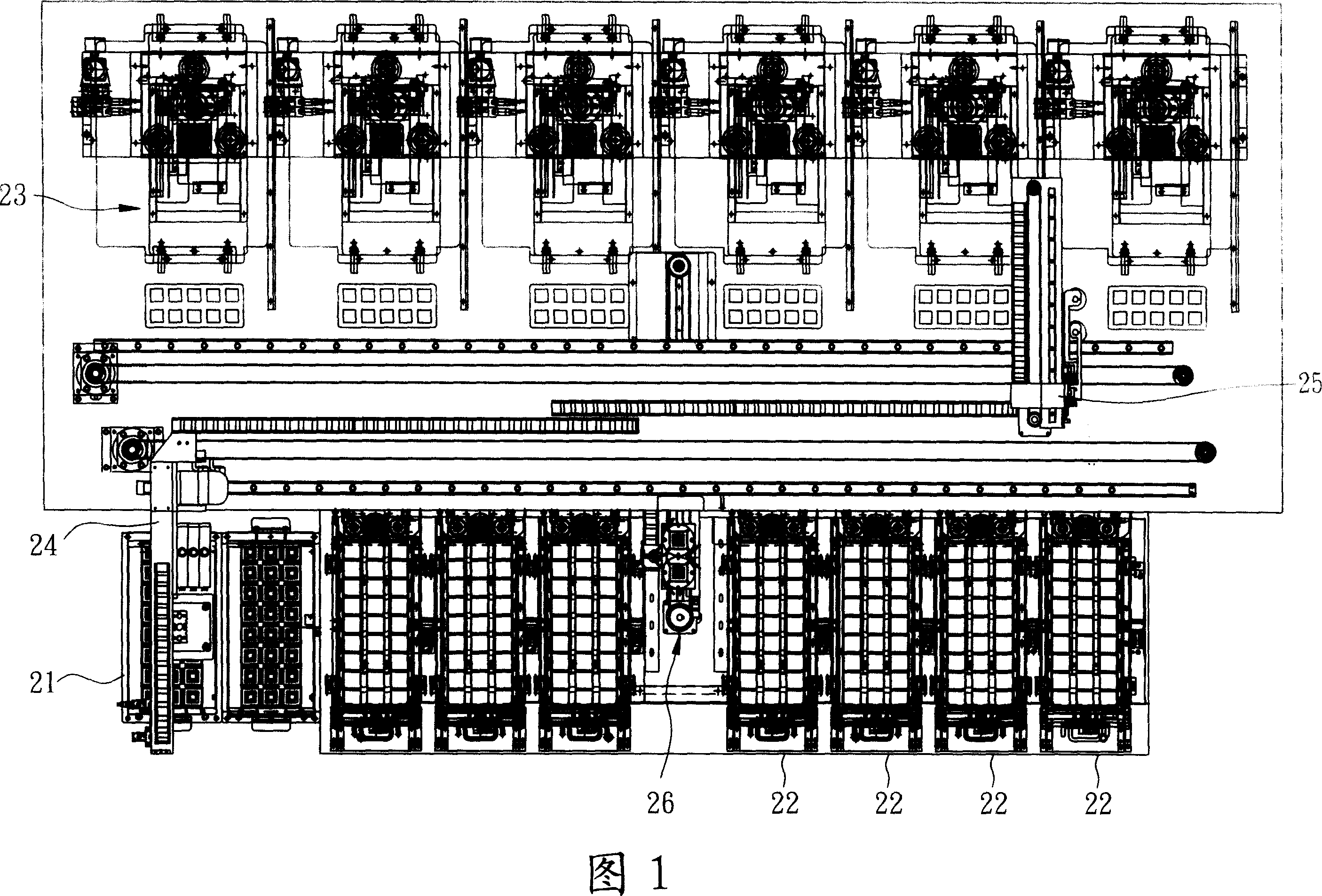

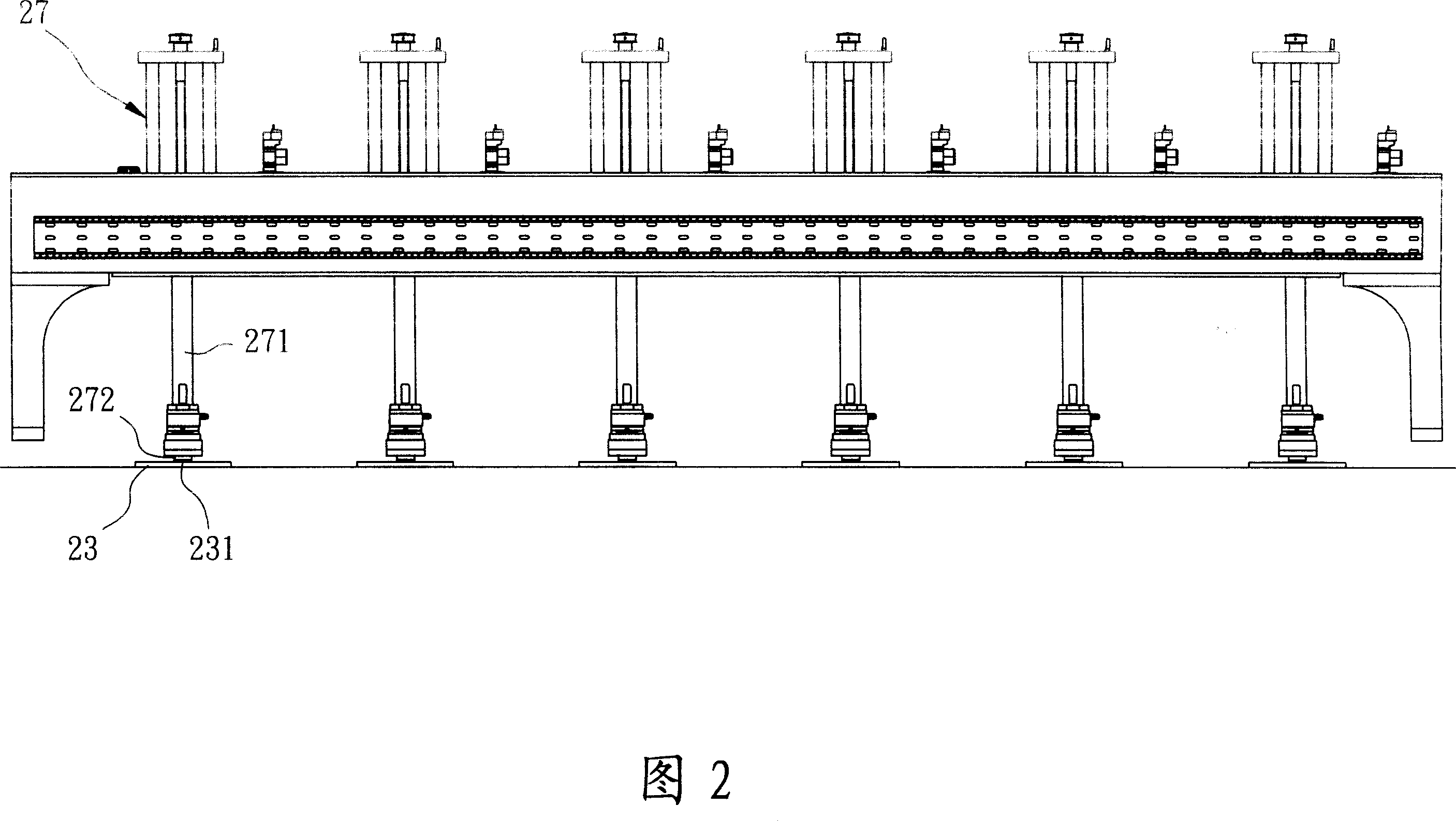

[0036] In order to enable your examiner to have a further in-depth understanding of the present invention, a preferred embodiment is hereby exemplified and described as follows in conjunction with the drawings:

[0037]Referring to Fig. 3 and Fig. 4, the present invention is provided with a liftable supply box 30, a liftable empty box 31, a liftable good product receiving box 32, 33 on the front side and the peripheral side of the machine, and The receiving boxes 34, 35, 36, 37 for defective products are provided with an input terminal IC conveying mechanism 40 on the side of the feeding box 30, and output terminals are provided on the sides of the receiving boxes 34, 35, 36, 37 IC delivery mechanism 41, the input end IC delivery mechanism 40 is provided with a pick-and-place head 401 with several suction nozzles, and the pick-and-place head 401 can be used for the first, second, and third directions (X, Y, and Z axial directions). Displacement, to absorb and displace the IC t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com