Rotor for motor and manufacturing method therefor

A motor and rotor technology, applied in the field of bonded magnet rotors for motors, can solve problems such as difficulty in easily magnetizing shafts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] Embodiment 1, comparative example 1

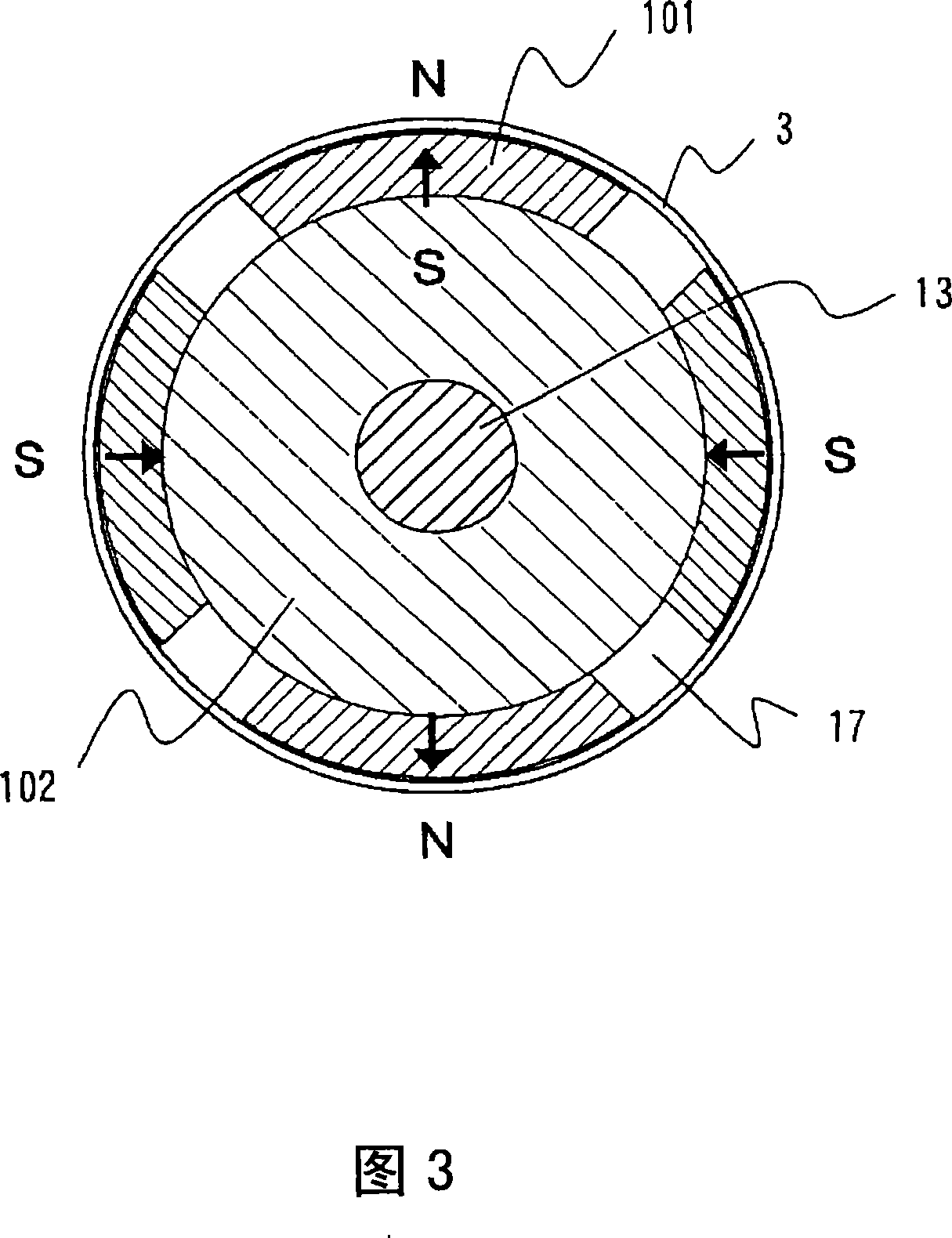

[0097] First, the advantages of the manufacturing method of the present invention, that is, the effective use of the bonding strength between the bonded magnet portion and the soft magnetic yoke portion, and the effect of abolishing the guard ring will be studied. In the conventional method of bonding sector magnets (comparative example 1), as shown in FIG. 3 , a guard ring is necessary. In view of this point, when using the rotor produced by the manufacturing method of the present invention (Fig. 1(a)), since the rare earth bonded magnet portion and the soft magnetic yoke portion composed of soft magnetic powder can be firmly integrated, A guard ring is not required, and since the gap between the stator and the rotor can be reduced, the magnetic flux of the magnet can be used more effectively than Comparative Example 1. It is also possible to avoid an output drop caused by eddy current loss in the guard ring in the high-frequency ...

Embodiment 2

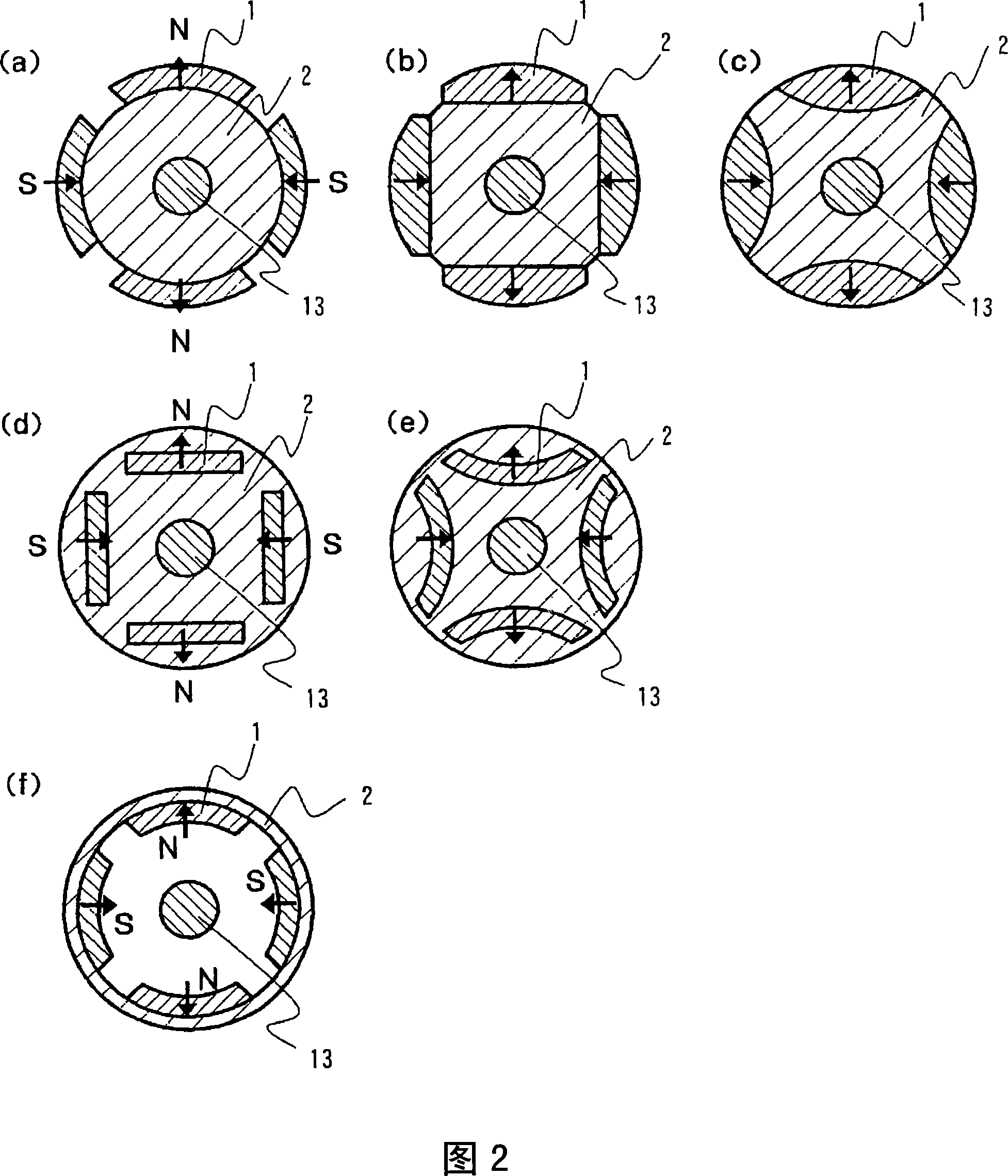

[0104] Fig. 1 is a schematic sectional view of a permanent magnet rotor according to another embodiment of the present invention. In FIG. 1, two magnets 1A, 1B, a yoke 2 made of soft magnetic material, and a shaft 13 constitute one magnetic pole. A plurality of such complicated shapes and orientations of permanent magnets can be provided by the manufacturing method of the present invention. As shown in Fig. 1, when the magnetization direction of the magnet is joined in a line-symmetric manner with respect to the joining surface 100 (the dotted line connecting N and S in the figure), the generated magnetic field is efficiently concentrated on the magnetic pole indicated by N(S) in the figure At the central position, higher magnetic properties can be obtained compared to the structure in which one magnetic pole is constituted by a single magnet as shown in FIG. 2 . The concentration of the generated magnetic field is related to the magnetic inclination. The magnet material, si...

Embodiment 3

[0107] Fig. 10 is a schematic sectional view of a permanent magnet rotor according to another embodiment of the present invention. In the conventional ring magnet manufacturing method, as shown in Fig. 10(a), orientation and multi-pole orientation of magnets having a large thickness in the direction of magnetization are difficult, but in the manufacturing method of the present invention, regardless of the poles of the magnet Regardless of the number and size, stable orientation and magnetization can be easily performed. In addition, as shown in FIG. 10( b ) and FIG. 10( c ), even if one pole is constituted by three magnets 1A to 1C, the generated magnetic field can be efficiently concentrated at the center of the magnetic pole.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com