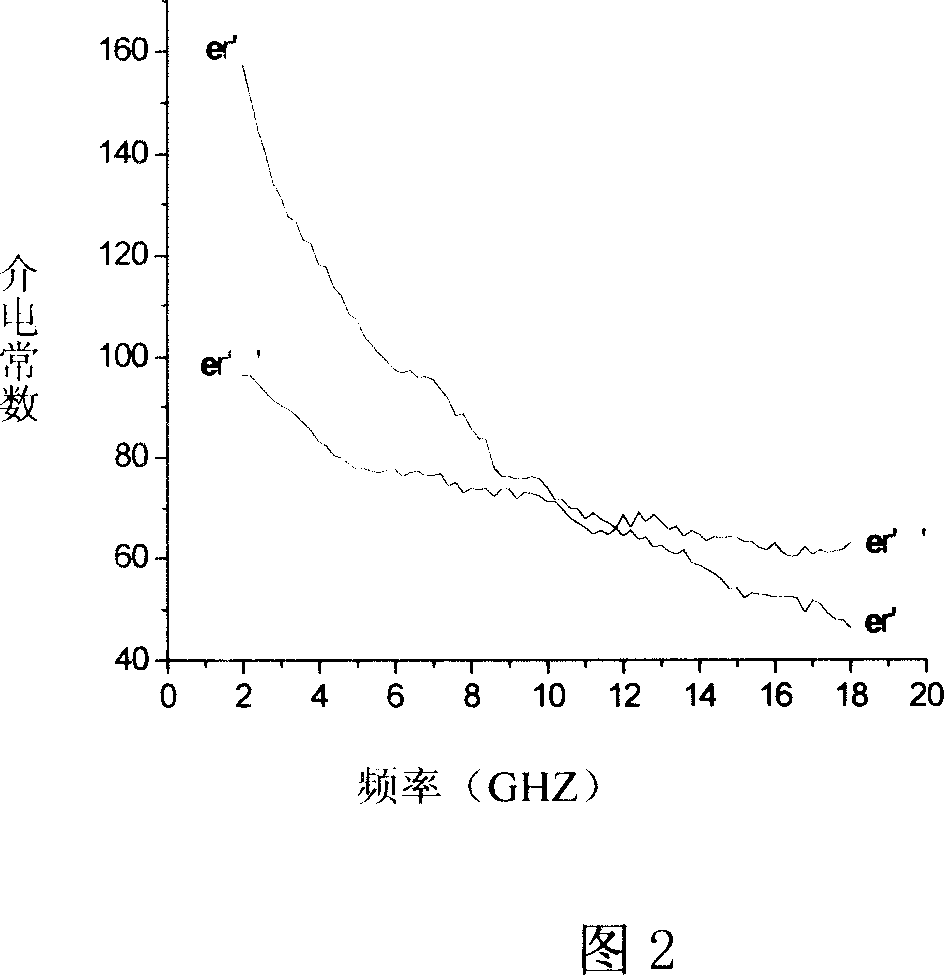

Electromagnetic shielding material of coverage compound carbon base and its making method and purpose

An electromagnetic shielding material and shielding material technology, applied in the direction of magnetic/electric field shielding, shielding, electrical components, etc., to achieve the effect of overcoming non-magnetism, simple preparation method, and improved comprehensive stealth performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1). Iron carbonyl and graphite powder (10 × 90 microns, thickness less than 2 microns) are mixed in a ratio of 80: 20 by weight; the coated particle raw material and the coating material The liquid raw material is placed in a reactor, stirred and suspended by an electromagnetic levitation stirrer, and the magnetic flux density maintained by the electromagnetic levitation stirrer in the reactor ranges from zero to three tesla;

[0024] (2). Nitrogen gas is passed into the suspension liquid in step (1), under nitrogen atmosphere, the reaction system is made to produce microbubbles to form a fluidized suspension system in which the solid-liquid-gas three-phase fully contacts, and the reaction suspension system is heated at the same time to react After fully reacting the mixture of step (1) for 10 hours at a temperature of 75°C, the final reactant becomes a powder product, and then heat-treats the resulting product in a nitrogen atmosphere at 180°C for 0.5 hour to obtain ir...

Embodiment 2

[0026] (1). Mix iron carbonylate and 30mm long carbon fiber powder in a ratio of 90:10 by weight; put the coated particle raw material and the liquid raw material of the coated substance in a reaction kettle, and stir with electromagnetic suspension The electromagnetic levitation stirrer keeps the magnetic flux density in the reactor in the range of zero to three tesla;

[0027] (2). Nitrogen gas is passed into the suspension liquid in step (1), under nitrogen atmosphere, the reaction system is made to produce microbubbles to form a fluidized suspension system in which the solid-liquid-gas three-phase fully contacts, and the reaction suspension system is heated at the same time to react At a temperature of 85°C, fully react the mixture of step (1) for 10 hours, make the final reactant into a powder product, and then heat-treat the resulting product in an argon atmosphere at 300°C for 1 hour to obtain a core / shell Shaped composite carbon fiber electromagnetic shielding material...

Embodiment 3

[0029] (1). After mixing iron carbonylate and nickel carbonylate at a ratio of 50:50 by weight, and then mixing them with elongated graphite powder (10×150 microns, thickness less than 2 microns) at a ratio of 50:50 by weight Proportional mixing; put the coated particulate raw material and the liquid raw material of the coated substance in a reaction kettle, stir and suspend with an electromagnetic suspension stirrer, and the magnetic flux density maintained by the electromagnetic suspension stirrer in the reaction kettle ranges from zero to three tesla;

[0030] (2). Nitrogen and argon are passed into the suspension liquid in step (1), and under the mixed atmosphere of nitrogen and argon, microbubbles are produced in the reaction system to form a fluidized suspension system in which solid-liquid-gas three-phase fully contacts, and at the same time Heat the reaction suspension system, at a reaction temperature of 85°C, fully react the mixture of step (1) for 10 hours, and make...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com