Large-sized fitting circular seam solder displacement machine

A technology of girth welding and positioner, which is applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., which can solve the problems of axial movement, welding inconvenience, and the inability to meet the synchronous linkage between automatic welding equipment and positioner and other issues to achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

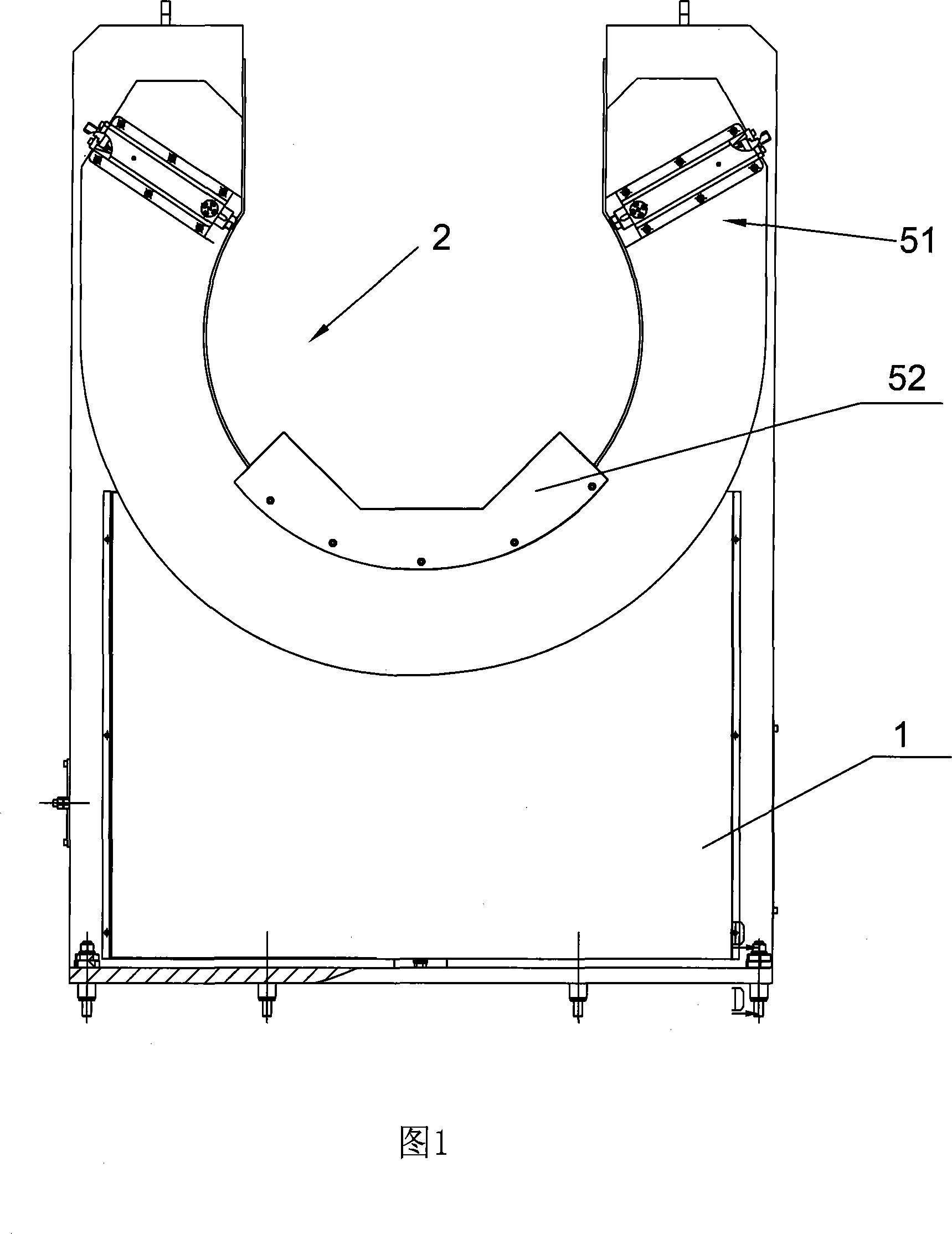

[0030] The positioner shown in Figure 1 includes a frame body 1, a rotation displacement mechanism 2 arranged on the frame body 1, and a rotation displacement mechanism 2 arranged on the frame body 1 to drive the rotation Displaced transmission mechanism 3.

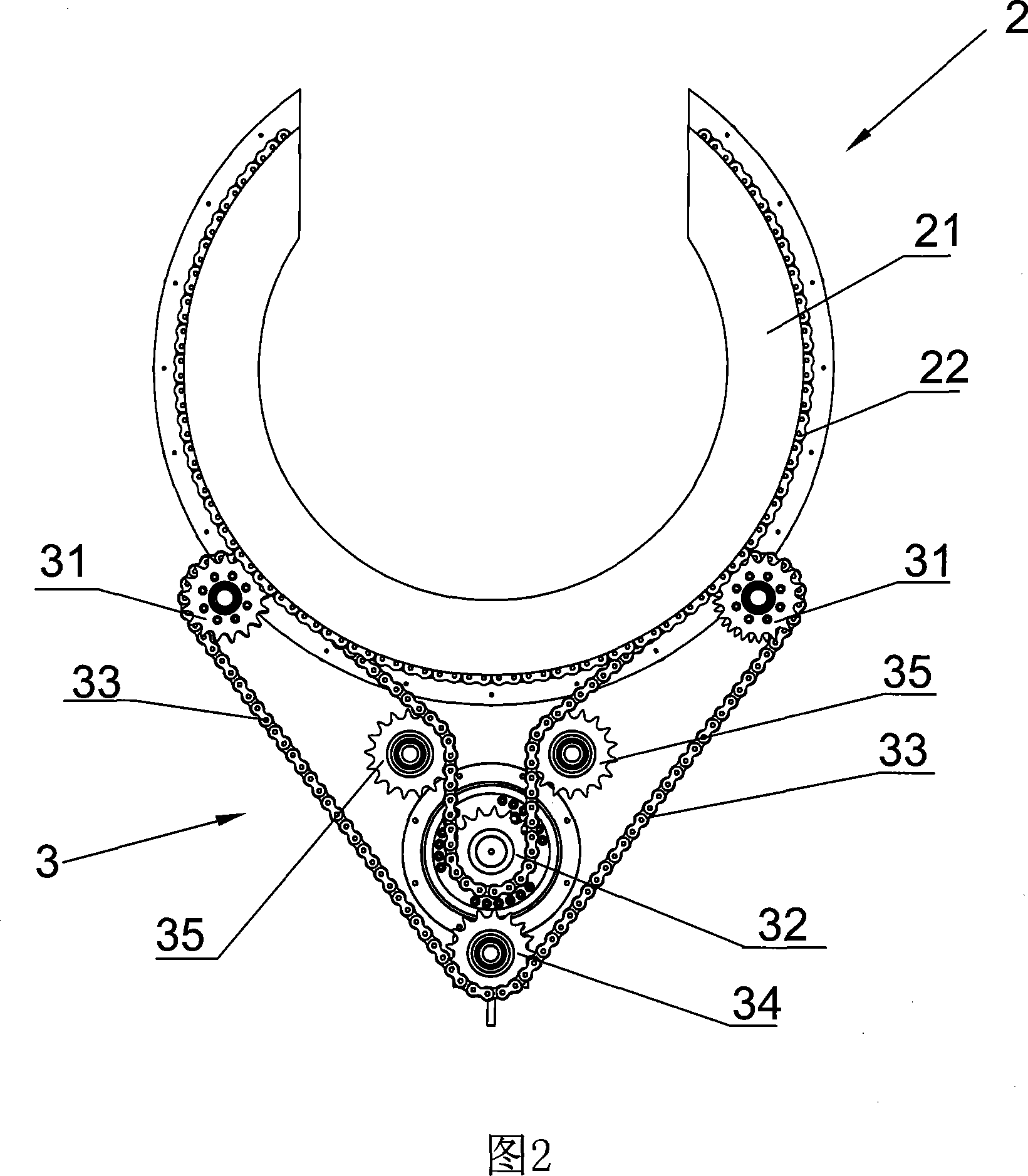

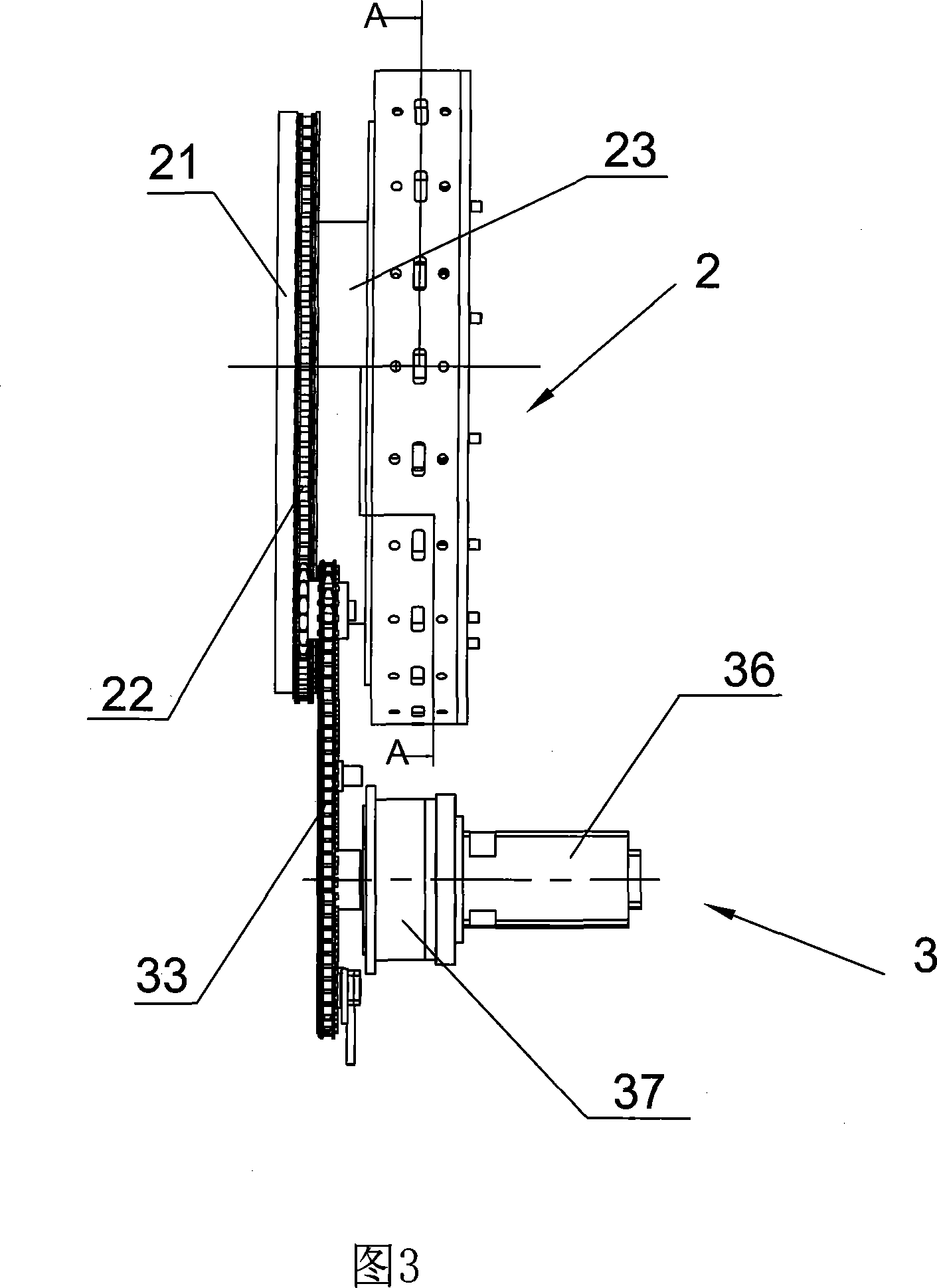

[0031] Wherein, as the rotary displacement mechanism 2 shown in accompanying drawing 2 to accompanying drawing 4, it comprises the rotating disk 21 that has cavity 212, and the diameter of rotating disk 21 can be made larger, and corresponding cavity 212 is also opened larger, This can accommodate pipe fittings of different diameters and sizes to be welded.

[0032] The turntable 21 is also radially provided with a gap 211 communicating with the cavity 212, through which the pipe fitting 6 to be welded can be conveniently inserted into the cavity of the turntable, so this kind of positioner Also known a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com