A New Condenser Microphone Diaphragm and Its Condenser Microphone

A capacitor microphone and capacitor technology, applied in the direction of electrostatic transducer microphones, electromechanical sensors, sensors, etc., can solve problems such as limiting transduction efficiency, diaphragm fatigue, distortion, etc., to avoid partition vibration, reduce initial stress, and improve performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

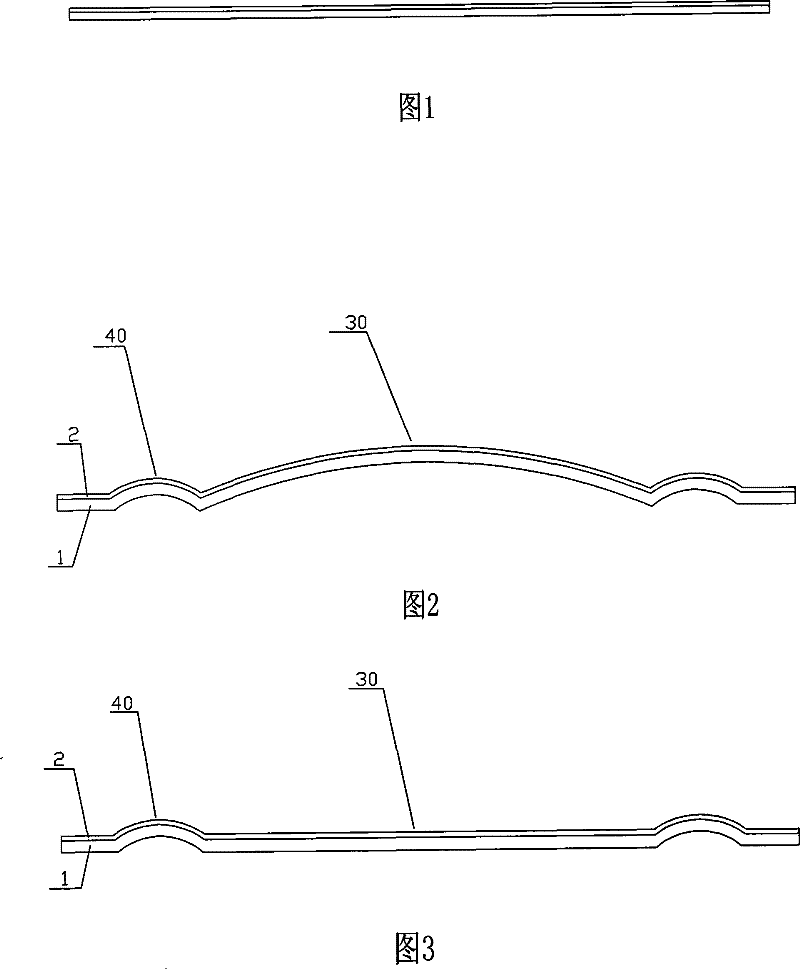

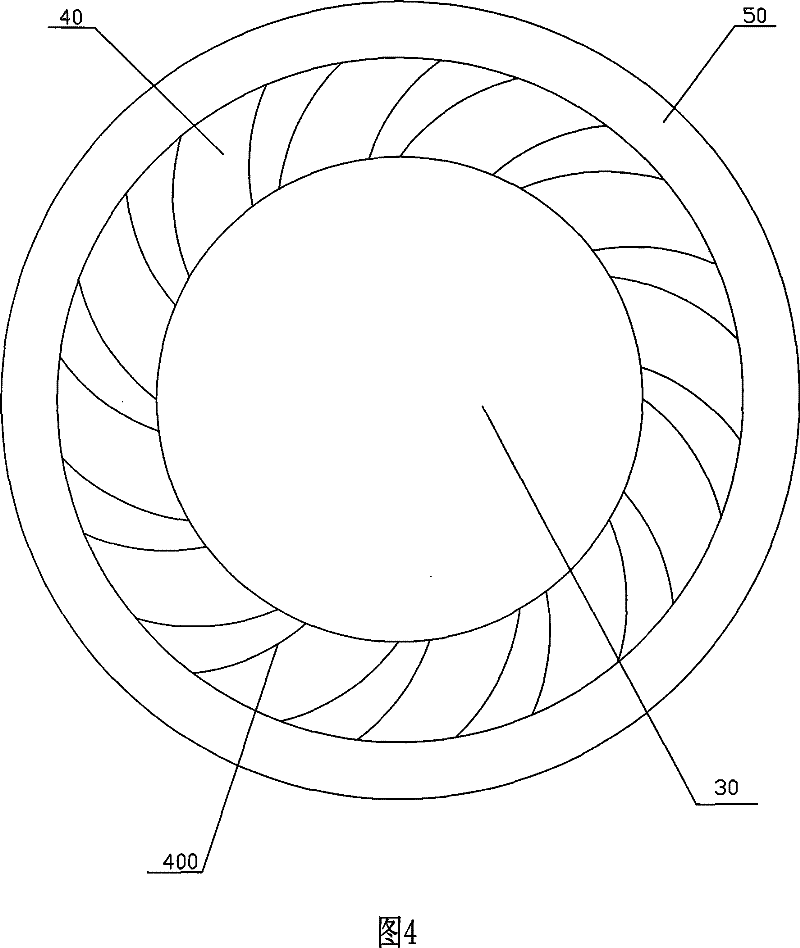

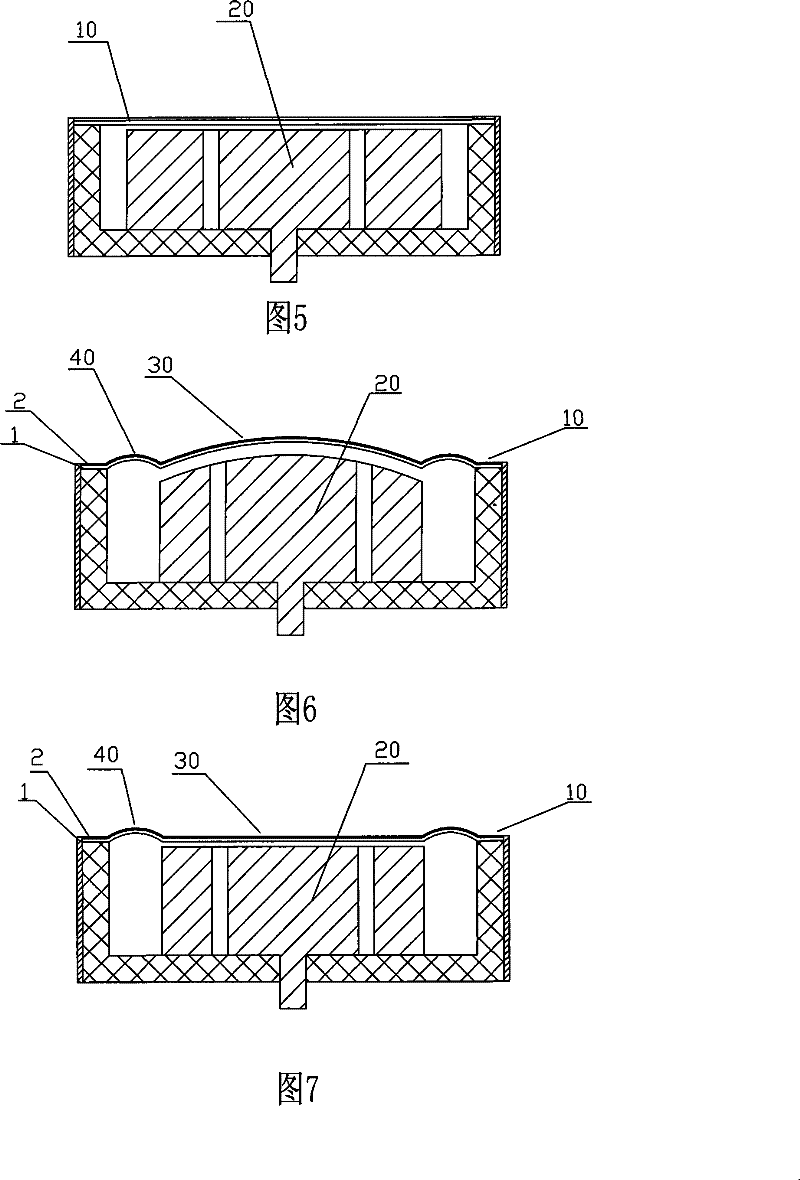

[0019] refer to figure 2 , image 3 , Figure 4 , a novel capacitor microphone diaphragm of the present invention, the diaphragm includes a diaphragm 1, the upper surface of the diaphragm 1 is coated with a metal film layer 2, the central part of the diaphragm is an effective transducing capacitor part 30, and its edge There are one or more arc-shaped protruding rings 40 for suspending / supporting the effective transducing capacitor part 30, which can effectively reduce the initial stress of the diaphragm and make the whole vibration system have sufficient elasticity. The production of the diaphragm is to firstly press the plastic film and then carry out electroplating; or to carry out electroplating on the plastic film and then carry out press molding.

[0020] As an embodiment of the present invention, refer to image 3 As shown, the effective transducing capacitor portion 30 of the diaphragm can be planar.

[0021] And further, of course, as a preferred embodiment of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com