Method for etching Chinese silk

A Chinese silk and etching technology, applied in the field of etching, can solve problems such as the inability to achieve hollowing effects, achieve the effect of preventing loosening and spinning, and expanding publicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

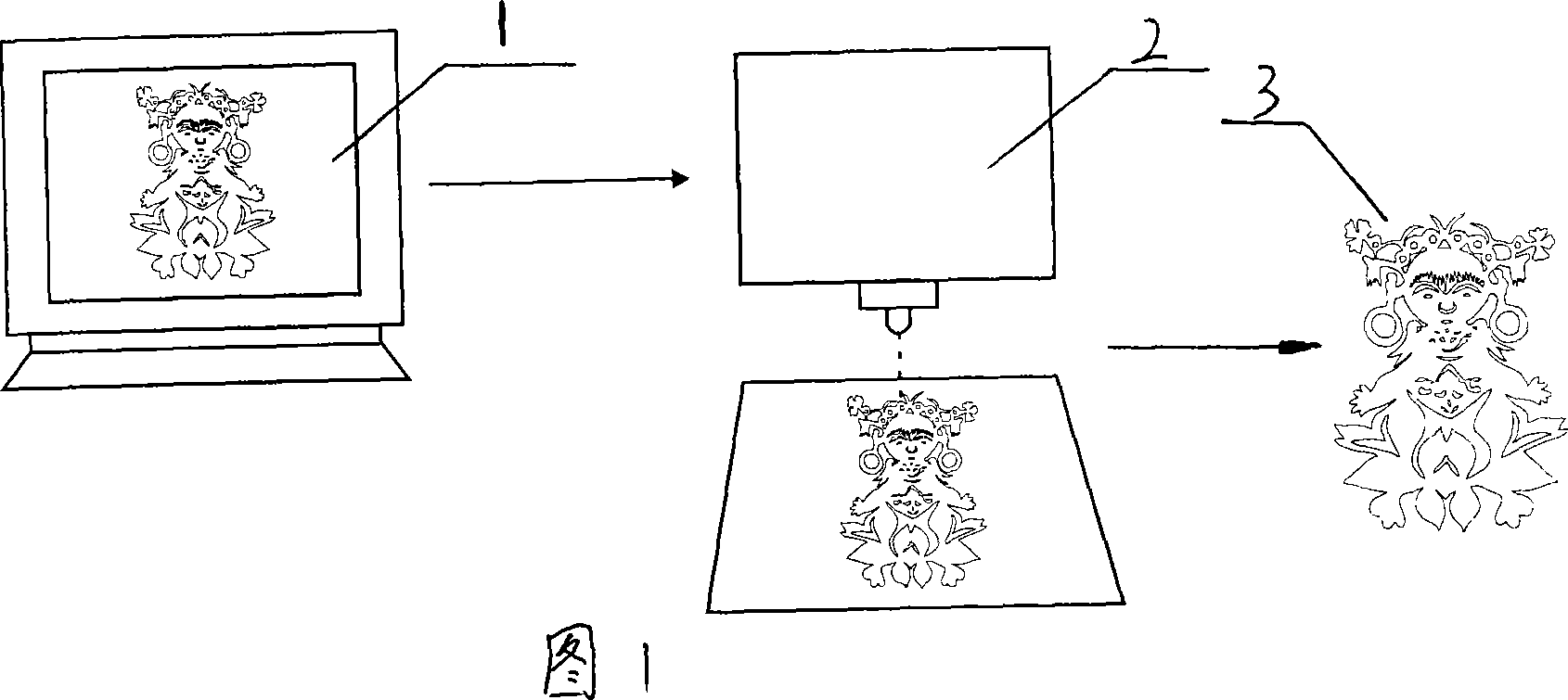

[0020] Fig. 1 is a kind of specific embodiment of the present invention. This embodiment includes flattening silk and using laser hot-melt technology to engrave fine and hollow silk artwork, which can reach a level of fineness that is difficult to achieve manually, and can prevent silk from being drawn and detached.

[0021] Operation steps (1):

[0022] Smooth silk. Put the silk flat on the work board, with the back of the silk facing up, spray water slightly with an ordinary watering sprinkler, and smooth the silk with a brush; "Fragrant paste" is fully blended with water at a ratio of 1:5, that is, one bottle of paste and five bottles of water), and evenly brushed on the smoothed silk; Glue on work board. Depending on the weather and the temperature in the working room, the silk is placed statically to dry. Due to the volatilization of water, the silk will be flattened, and due to the slurry water, the slurry left on the back of the silk will keep the silk flat, which is...

Embodiment 2

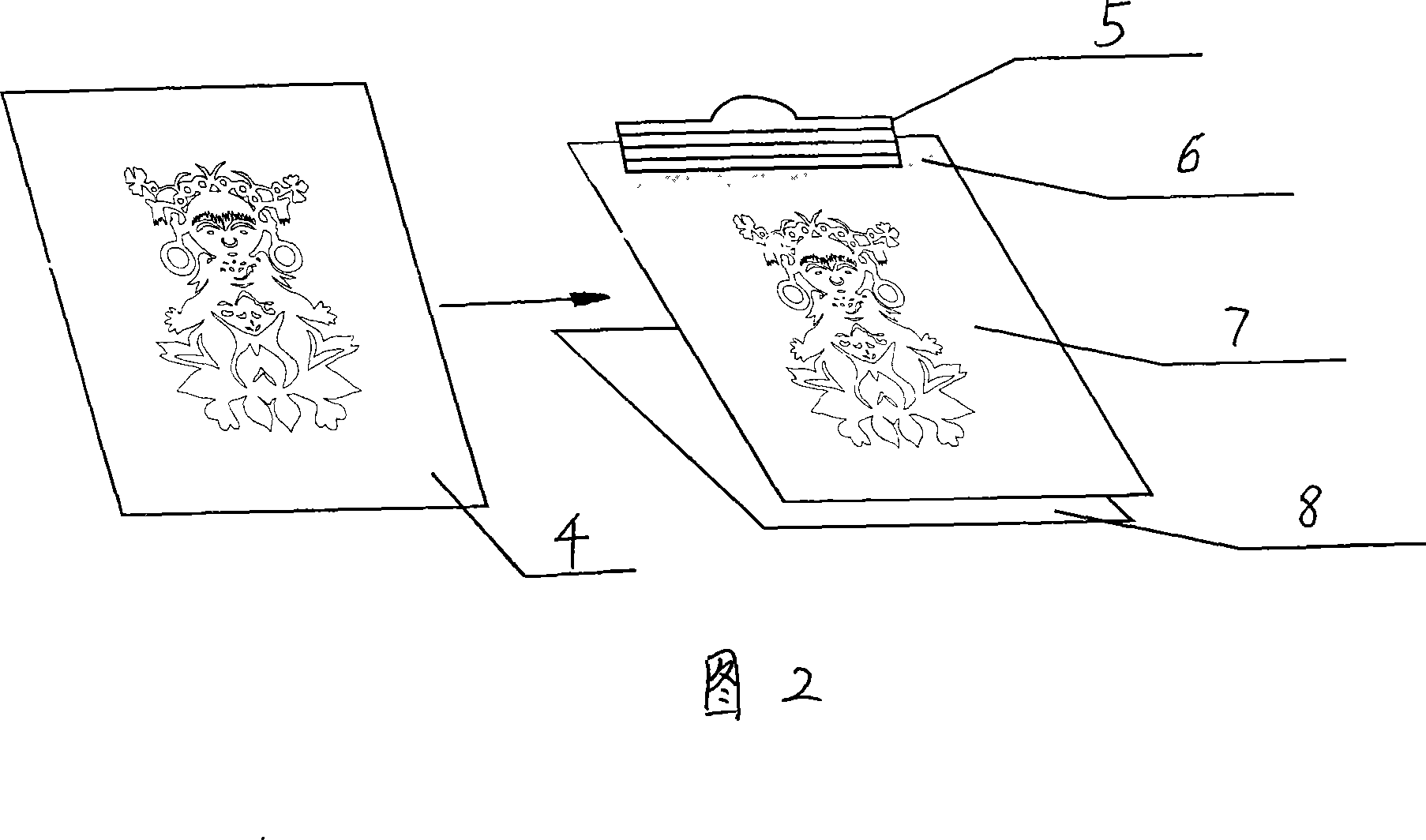

[0026] Fig. 2 is another specific embodiment of the present invention. This embodiment includes flattening silk and finely hollowing out silk artworks by using acidic color paste printing leakage corrosion method. The main breakthrough lies in the self-prepared acid printing paste, which can achieve the ideal silk picture by using acid abrasion, and can prevent the silk incision from spinning , The problem of detachment.

[0027] Operation steps (1):

[0028] The operation steps are the same as in "Example 1 Operation Steps (1)".

[0029] Operation steps (2):

[0030] Wax engraved master. Use high-quality 320 grams of coated paper as the base, draw the drawing on the paper, then heat the ordinary white wax to liquid, and paint evenly on the coated paper. The required picture is engraved on the paper manually or mechanically. The master is complete.

[0031] Operation steps (3):

[0032] Prepare acid color paste. Use 50% sulfuric acid (PH: 1-2) and carbon powder (C) to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com