Production of oxidic nanoparticles

A technology of nanoparticles and oxides, which is applied in the direction of nanostructure manufacturing, titanium oxide/hydroxide, zirconium oxide, etc., and can solve the problems that cannot be carried out easily and continuously

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

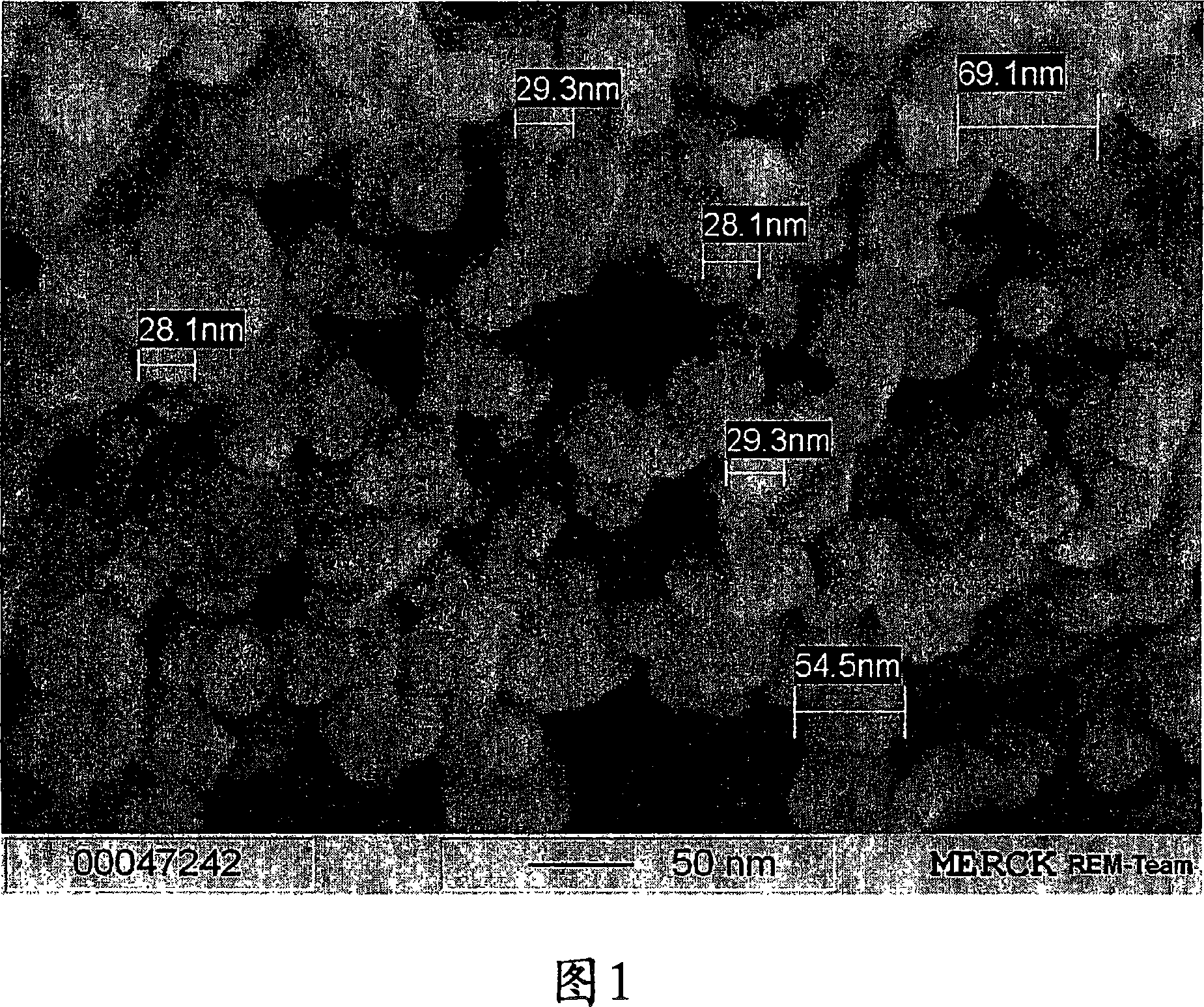

[0073] Nanoscale Titanium Oxide with Narrow Particle Size Distribution

[0074] A solution of titanyl sulfate (15% in dilute sulfuric acid, Aldrich) was prepared in a vessel. A solution of Span 80 (Fluka) and Lutensol TO3 (BASF) in cyclohexane (ratio 1.5:1.5:9 (wt%)) was prepared in a second vessel. From a storage container, the two solutions are fed by means of a gear pump through a micromixer as described in patent application DE 1 95 11 603 A1. (The micromixers used work on the "split-recombine" principle. Corresponding micromixers are currently sold under the trade name caterpillarmixers by the Institut für Mikromechanik Mainz). The volume streams are chosen such that their ratio is 1:5, based on the aqueous and organic phases. An emulsion is formed from a solution of starting materials. After mixing in a micromixer, the resulting emulsion was added directly via a thin line to a solution consisting of 60 wt% cyclohexane and 40 wt% methoxyethylamine. Upon addition to th...

Embodiment 2

[0079] The method was carried out as described in Example 1, except that the continuous phase now consisted of a solution of Span 80 (Fluka) and Lutensol TO3 (BASF) in cyclohexane (ratio 1.5:1.5:18 (wt %)).

[0080] The particles obtained have a diameter of 80-120 nm and are likewise redispersible in organic solvents.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com