Magnetic head assembly and magnetic disc driver

A magnetic head assembly and magnetic head technology, which is applied in the field of disk drives, can solve the problems of easy damage of the magnetic head and inconvenient installation of the magnetic head assembly, and achieve the effect of convenient assembly and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

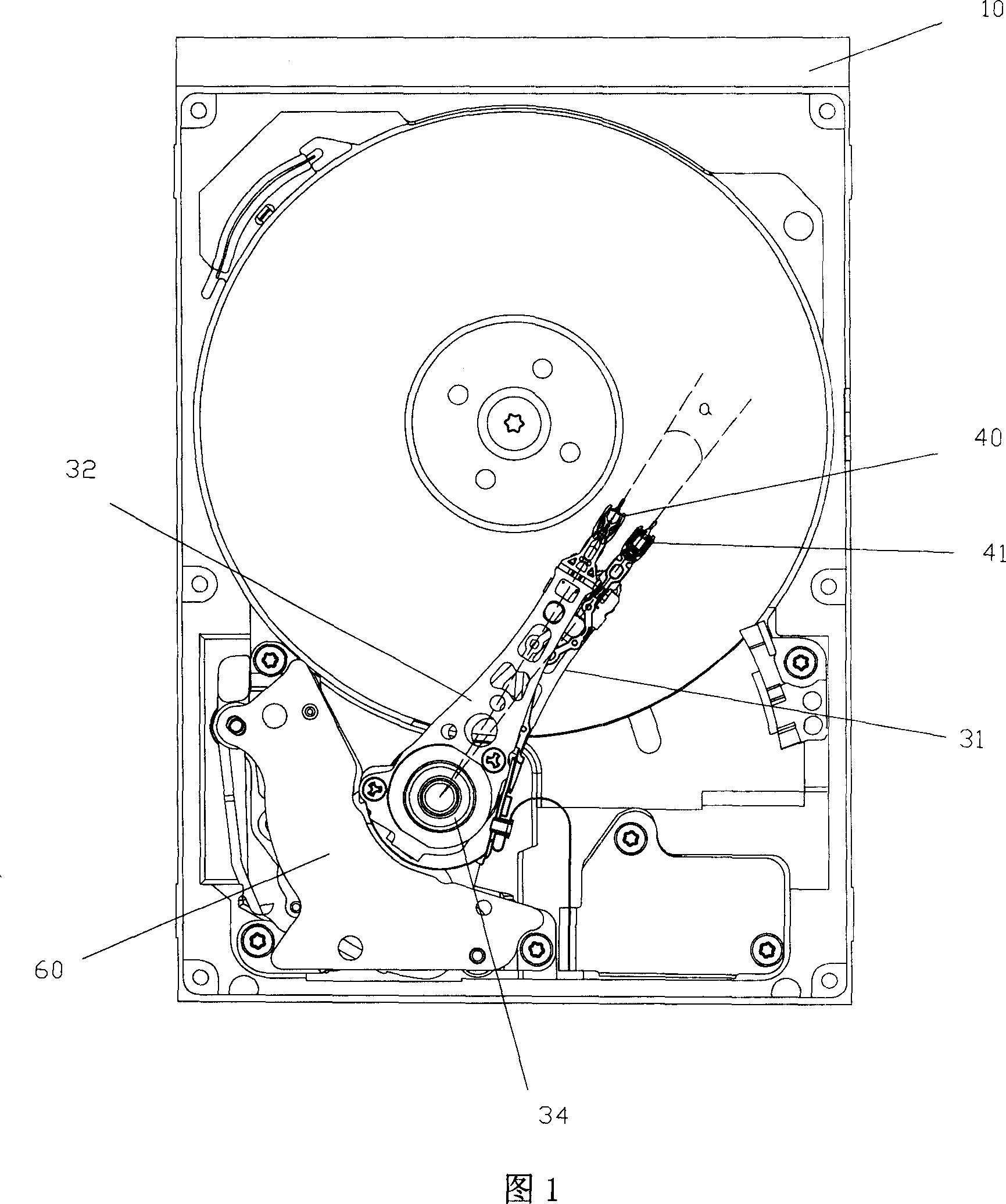

[0015] Please refer to FIG. 1 to FIG. 3 , a novel disc drive of the present invention includes a disc base 10 , a magnetic head assembly and a voice coil motor 60 for driving the magnetic head assembly to rotate.

[0016] A disk installation area is formed in a recess on the disk base 10, and at least one disk (not shown) is installed in the disk installation area. The magnetic head assembly is installed on one side of the disk.

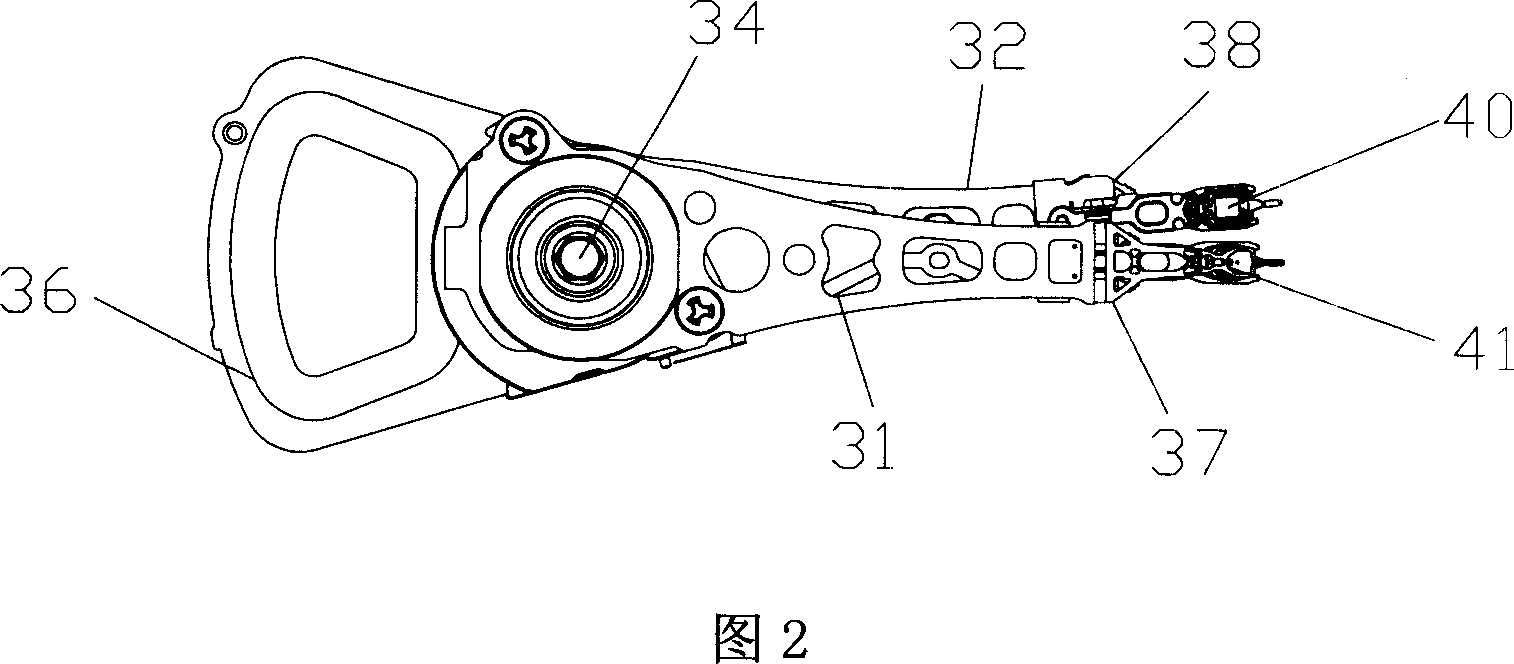

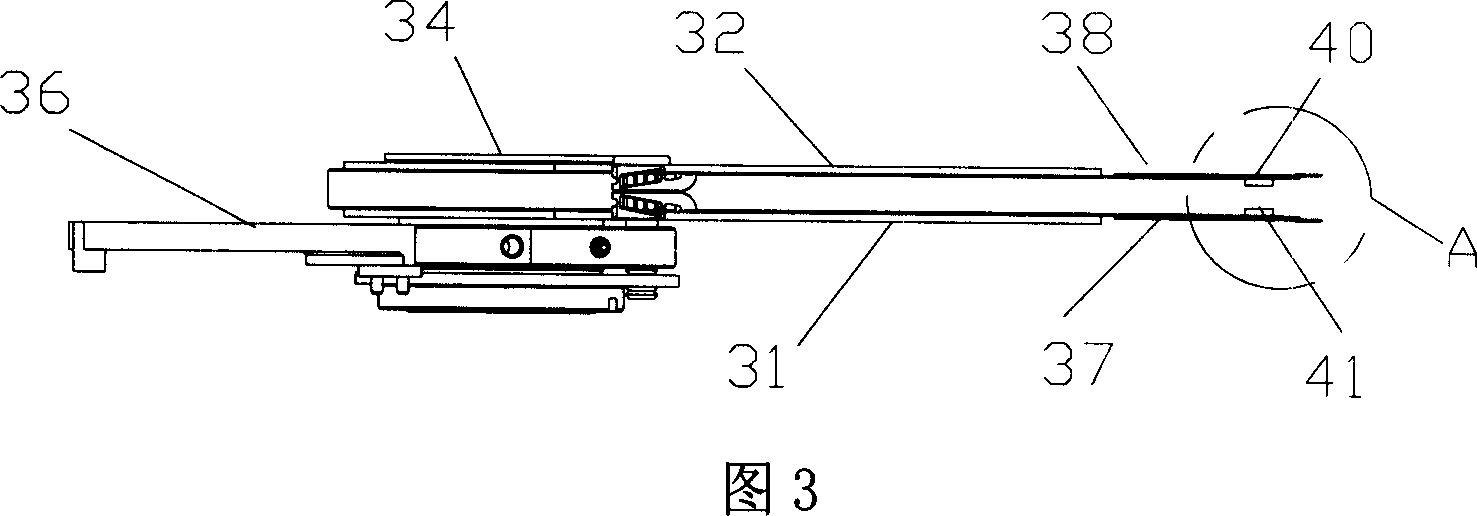

[0017] The magnetic head assembly includes several suspension arms. In this embodiment, two suspension arms 31 and 32 are used. Ends of the cantilever 31 and the cantilever 32 are respectively connected to elastic carrying arms 37 and 38 . Magnetic heads 41 and 40 are suspended from the ends of the carrying arms 37 and 38 respectively. The cantilevers 31 , 32 are fixed on a bearing 34 , and the bearing 34 is supported on a rotating shaft (not shown) on the base 10 .

[0018] Please also refer to FIG. 4 , the magnetic heads 41 and 40 at the ends of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com