Embroidering fabric and manufacturing method thereof

A production method and fabric technology, applied in the field of embroidery, can solve the problems of skin irritation, easy fluffing or pilling, etc., and achieve the effect of easy operation, no bad touch, and avoiding pilling or pilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

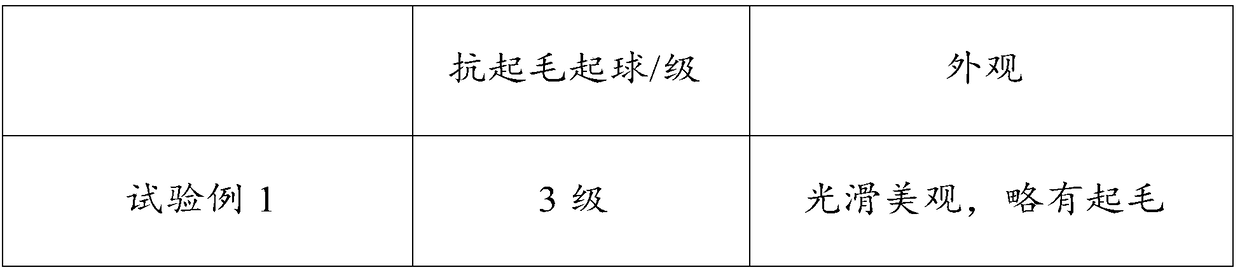

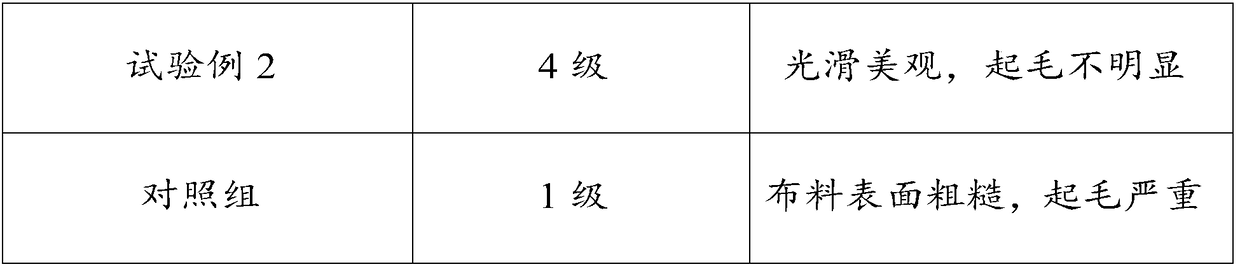

Examples

Embodiment 1

[0040] The cloth is dyed and dried for the first time to obtain the initial material, and the wax liquid containing beeswax, γ-cottonol and cericic acid in a weight ratio of 3:1:0.4 is applied to the surface of the embroidery thread. After the wax liquid is solidified, the initial material is For embroidery, soak the embroidered fabric in the soaking solution at 60°C for 6 hours, dry it, apply the smoothing agent three times, and dry it for the second time at 80°C after each application. The drying time is 15min.

[0041] Wherein, the soaking solution is obtained by mixing 2 parts by weight of formaldehyde-free color-fixing agent, 1 part by weight of polyvinylpyrrolidone and 8 parts by weight of water.

[0042] Smoothing agent is the starch graft sodium acrylate of 8 weight parts, the silicone rubber of 4 weight parts, the amino silicon microemulsion of 2 weight parts, the lauric acid ester-containing quaternary ammonium salt of 4 weight parts, the imidazoles of 1.5 weight parts...

Embodiment 2

[0044] The cloth is dyed and dried for the first time to obtain the initial material, and the wax liquid containing beeswax, γ-cottonol and cericic acid in a weight ratio of 3:1:0.4 is applied to the surface of the embroidery thread. After the wax liquid is solidified, the initial material is For embroidery, soak the embroidered fabric in the soaking solution at 60°C for 6 hours, dry it, apply the smoothing agent three times, and dry it for the second time at 80°C after each application. The drying time is 15min.

[0045] Wherein, the soaking solution is obtained by mixing 2 parts by weight of formaldehyde-free color-fixing agent, 1 part by weight of polyvinylpyrrolidone and 8 parts by weight of water.

[0046] Smoothing agent is the starch graft sodium acrylate of 10 weight parts, the silicone rubber of 5 weight parts, the amino silicon microemulsion of 3 weight parts, the lauric acid ester-containing quaternary ammonium salt of 5 weight parts, the imidazoles of 2 weight part...

Embodiment 3

[0048] The cloth is dyed and dried for the first time to obtain the initial material, and the wax liquid containing beeswax, γ-cottonol and cericic acid in a weight ratio of 3:1:0.4 is applied to the surface of the embroidery thread. After the wax liquid is solidified, the initial material is For embroidery, soak the embroidered fabric in the soaking solution at 60°C for 6 hours, dry it, apply the smoothing agent three times, and dry it for the second time at 80°C after each application. The drying time is 15min.

[0049] Wherein, the soaking solution is obtained by mixing 2 parts by weight of formaldehyde-free color-fixing agent, 1 part by weight of polyvinylpyrrolidone and 8 parts by weight of water.

[0050] The smoothing agent is the starch graft sodium acrylate of 8.5 parts by weight, the silicone rubber of 4.2 parts by weight, the amino silicon microemulsion of 2.2 parts by weight, the lauric acid ester-containing quaternary ammonium salt of 4.4 parts by weight, the imid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com