Vacuum valve drive

A technology for actuators and vacuum valves, applied in the direction of sliding valves, valve details, valve devices, etc., can solve the problem of increased particle generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

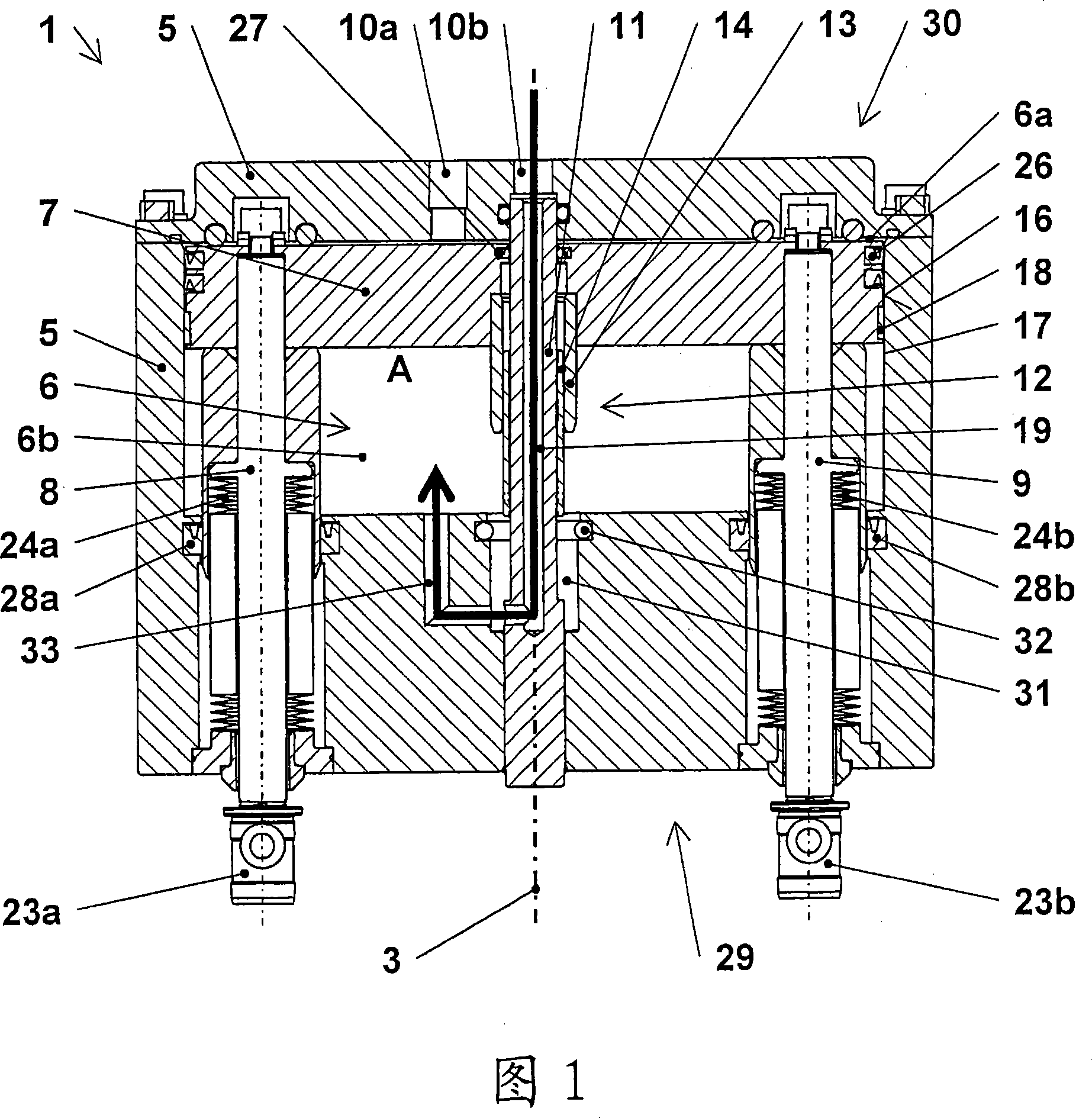

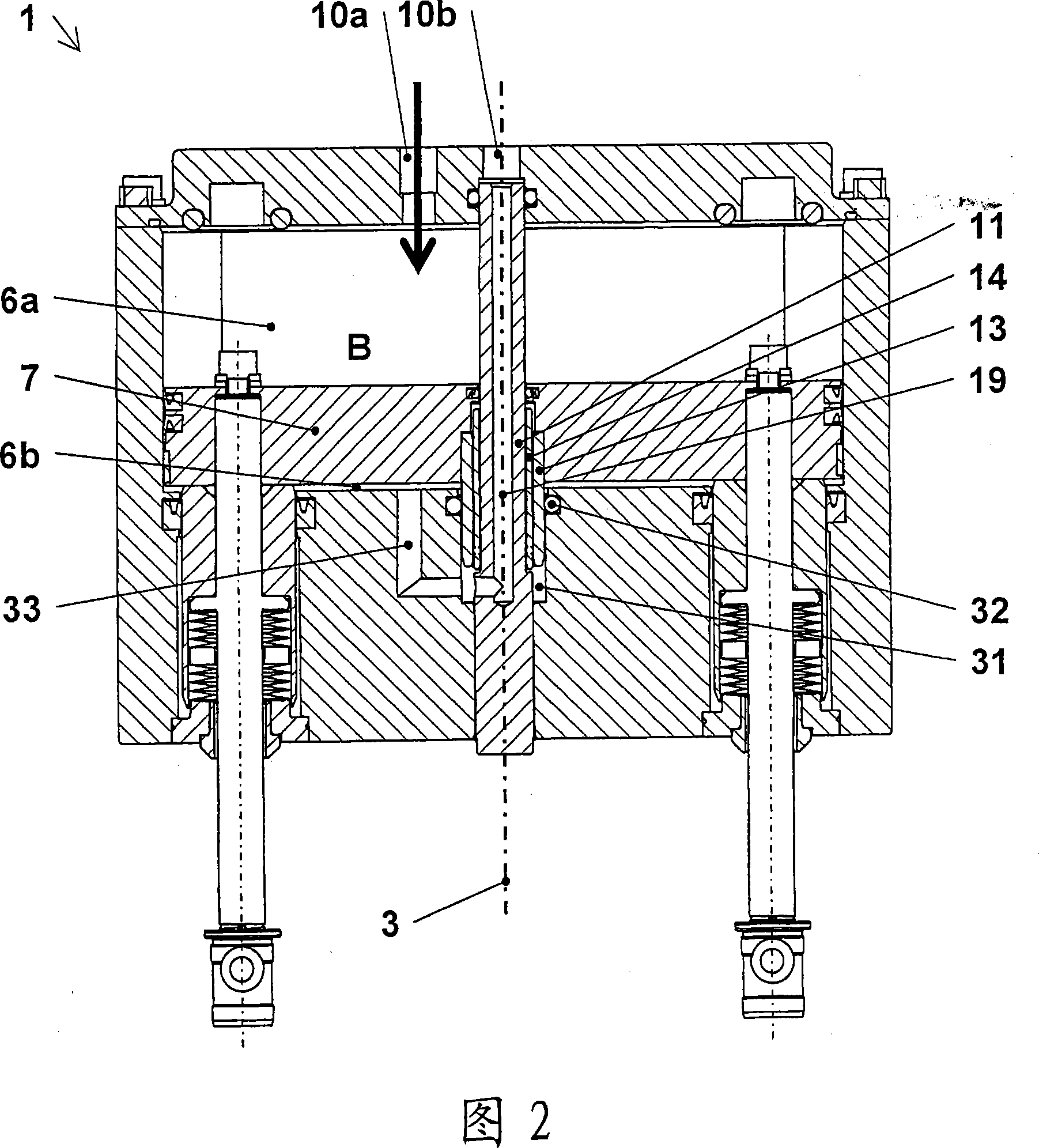

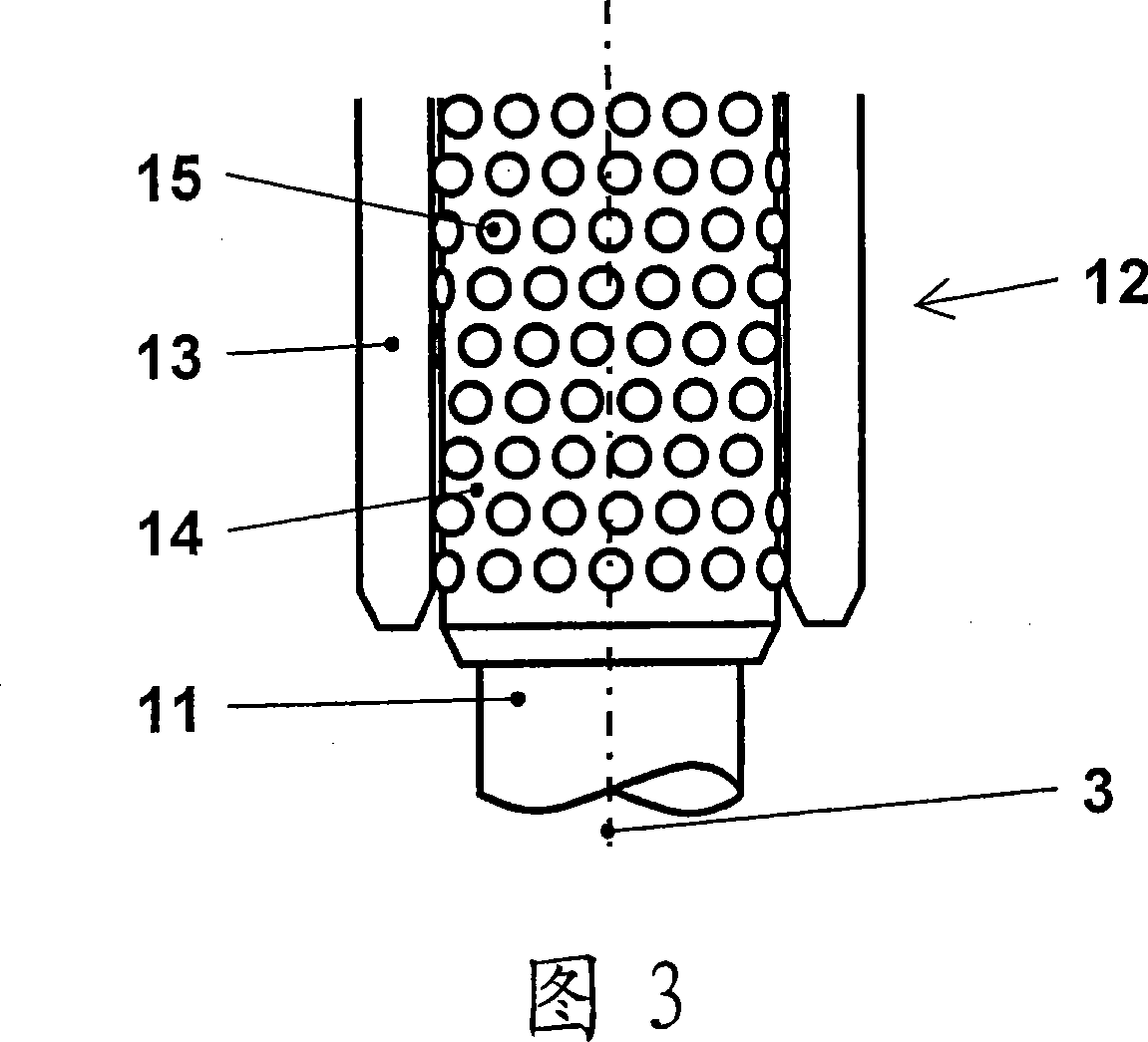

[0024] In the following, FIGS. 1 to 5 are described together in some cases, and the reference numerals that have been explained in advance in each figure will not be described separately. Figure 1 shows a possible embodiment of a vacuum valve actuator 1 according to the invention in a transverse sectional view in a fully open position A with a valve closure 2 mounted on the vacuum valve actuator 1 (cf. ) fully open. FIG. 2 shows the same vacuum valve driver 1 in the closed position B. As shown in FIG. The shown vacuum valve driver 1 comprises a multi-part driver housing 5 containing a substantially airtight working space 6 . The working space 6 has a channel-like cross-section in plan view in the direction of the adjustment axis 3 . A piston 7 displaceable along the adjustment axis 3 is arranged in the working space 6 in such a way that the piston 7 divides the working space 6 into a first pressure space 6 a on the connection side 30 and a second pressure space 6 a on the va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com