Process of extracting amomum oil resin from spring amomum fruit

A technology for Amomum oil and resin, which is applied in the production of fat oil/fat and fat production, can solve the problem of low total yield of oleoresin, and achieve the effects of improving the extraction rate, lowering the extraction temperature and reducing the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0019] 1. Amomum powder mixed with 4 times the volume of 95% ethanol, soaked for 15 minutes;

[0020] 2. Under the conditions of temperature 60°C and microwave power 200W, use dynamic microwave extraction equipment to process the above mixture for 13 minutes, and collect the filtrate after vacuum filtration;

[0021] 3. Take the filter residue and add 4 times the volume of 95% ethanol to extract according to step 2, repeat twice, and combine the filtrate;

[0022] 4. Concentrate the combined filtrate by distillation under reduced pressure at 0.09MPa until no solvent flows out.

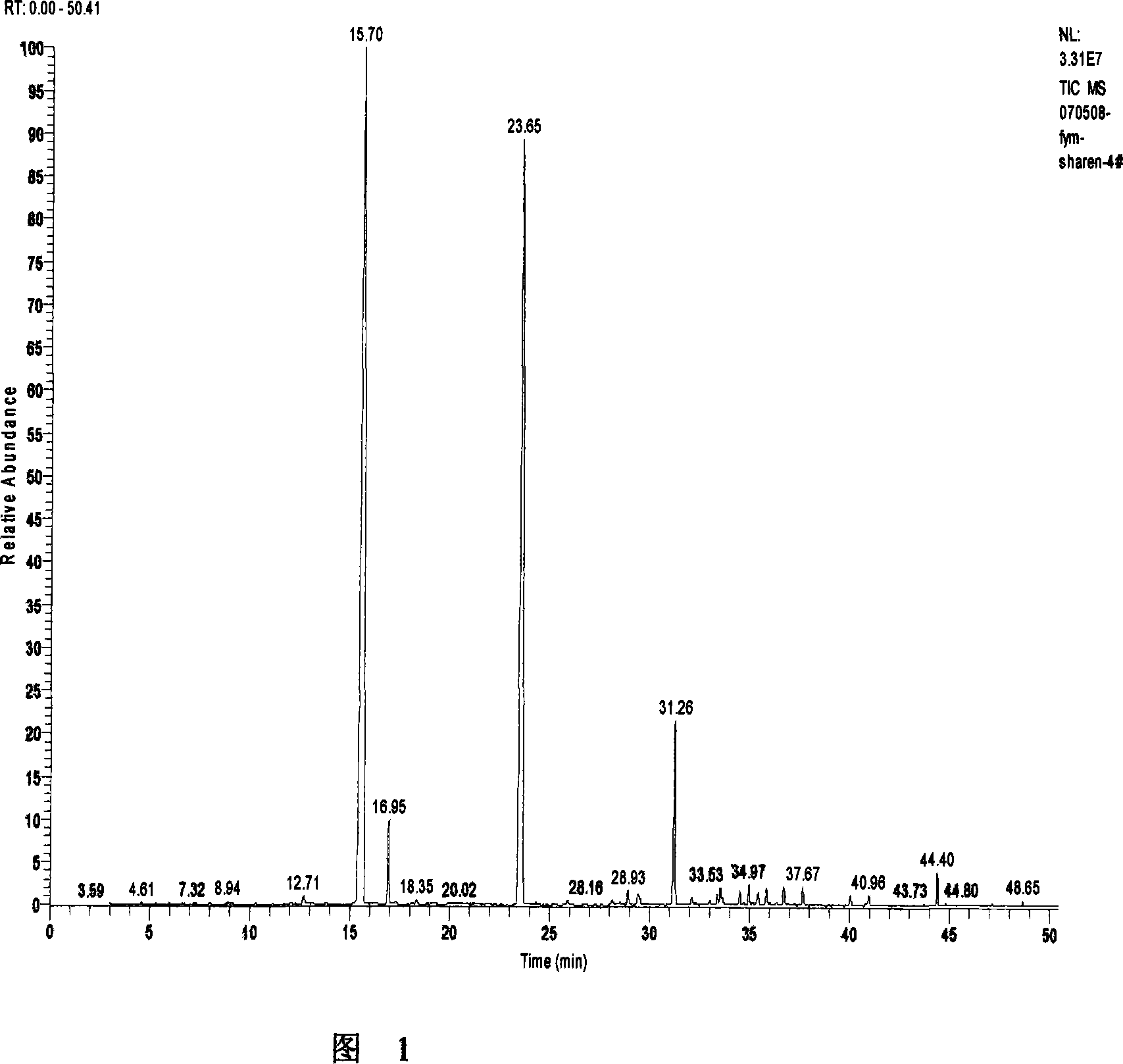

[0023] The yield of Amomum oleoresin extracted by the above method is 8.2%. Gained Amomum oleoresin further adopts gas chromatography-mass spectrometry to analyze the aromatic components therein, and the results are as shown in Figure 1, the top four compounds with the highest content are successively: the compound with retention time at 15.70 is (±)-camphor, The relative content reaches 48.12%; the ...

example 2

[0025] 1. Amomum powder mixed with 4 times the volume of 95% ethanol, soaked for 10 minutes;

[0026] 2. Under the conditions of temperature 78°C and microwave power 300W, use dynamic microwave extraction equipment to process the above mixture for 8 minutes, and collect the filtrate after vacuum filtration;

[0027] 3. Take the filter residue and add 3 times the volume of 95% ethanol to extract according to step 2, repeat twice, and combine the filtrate;

[0028] 4. Concentrate the combined filtrate by distillation under reduced pressure at 0.01 MPa until no solvent flows out.

[0029] The yield of Amomum oleoresin extracted by the above method is 8.7%. Gained Amomum oleoresin is further analyzed by gas chromatography-mass spectrometry, wherein the relative content of (±)-camphor reaches 50.22%, the relative content of bornyl acetate is 34.35%, the relative content of R-syringene is 3.45%, and the relative content of borneol is 1.11%.

example 3

[0031] 1. Amomum powder mixed with 5 times the volume of 95% ethanol, soaked for 20 minutes;

[0032] 2. Under the conditions of temperature 40°C and microwave power 100W, use dynamic microwave extraction equipment to process the above mixture for 13 minutes, and collect the filtrate after vacuum filtration;

[0033] 3. Take the filter residue and add 5 times the volume of 95% ethanol to extract according to step 2, repeat twice, and combine the filtrate;

[0034] 4. Concentrate the combined filtrate by distillation under reduced pressure at 0.03 MPa until no solvent flows out.

[0035] The yield of Amomum oleoresin extracted by the above method is 6%. Gained Amomum oleoresin is further analyzed by gas chromatography-mass spectrometry, wherein the relative content of (.±)-camphor reaches 45.66%, the relative content of bornyl acetate is 33.21%, the relative content of R-syringene is 7.21%, and the relative content of borneol was 3.11%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com