Wooden wind bell and its making process

A production method and the technology of wooden wind chimes, which are applied in wood processing, manufacturing tools, wood processing appliances, etc., can solve the problems of ear-piercing, surrounding living environment interference, high-frequency sound, etc., and achieve the effect of low noise and small sound wave transmission range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

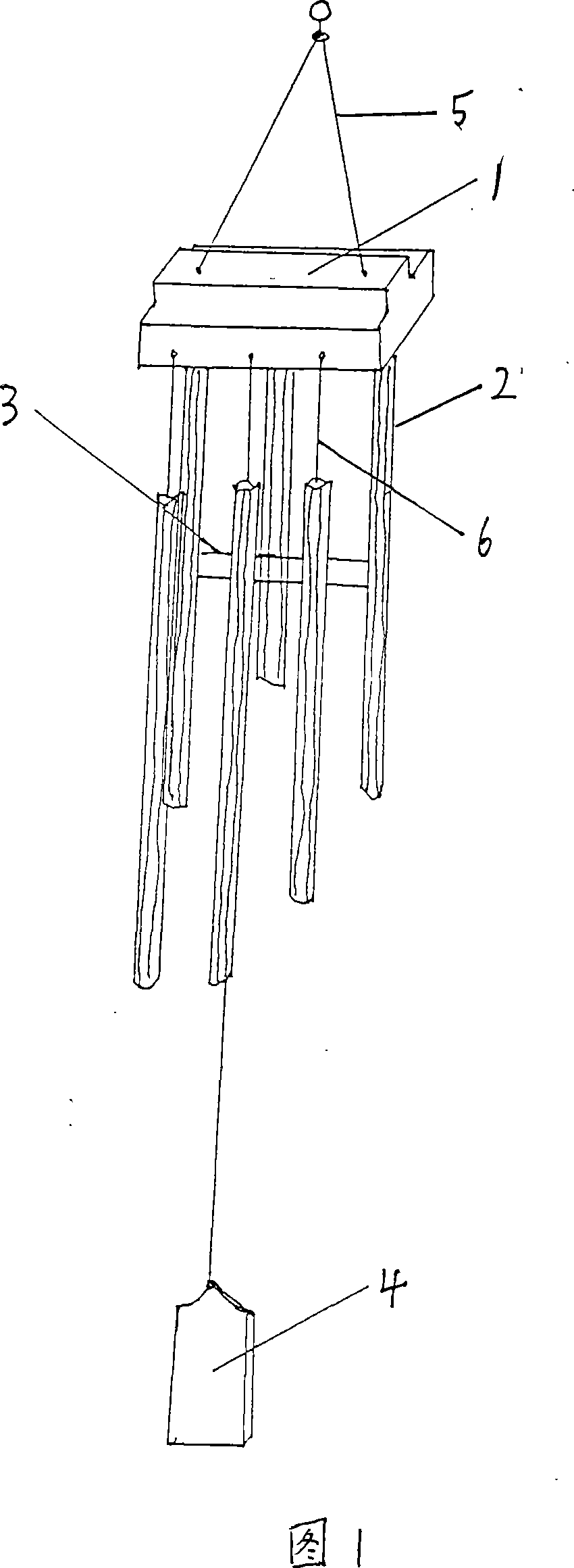

Image

Examples

Embodiment Construction

[0010] A wooden wind chime, which is assembled by using treated wood as various wind chime components; wherein the wood processing process is:

[0011] 1. Put wood with a dry humidity below 12 degrees and a thickness of 10-20 cm into high-pressure equipment with a pressure of 1.275 MPa. After vaporization treatment with superheated steam, then perform cycle air drying and deformation correction; the temperature of the superheated steam is 100 ° C ~160°C, the treatment time is 1 day to 7 days;

[0012] 2. After the vaporized wood is circulated and air-dried, then use CaO+H 2 O carry out sterilization treatment;

[0013] 3. Carry out coloring or cooking treatment according to the requirements of different components, and keep the dry humidity of the wood below 12 degrees;

[0014] 4. According to the shape requirements of different components, it is shaped by mechanical grinding.

[0015] In the present invention, wood with a dry humidity below 12 degrees and a thickness of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com