Filtering mode with pressurizing altered porosity of elastic filter material layer

A filter method and filter material layer technology, which is applied to loose filter material filters, filter separation, gravity filters, etc., can solve the problem that the upper layer of the filter material layer is easy to be blocked, the quality of the effluent is poor, and the filter material layer cannot be fully utilized. Function and other issues, to save backwash water, improve filtration efficiency and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0008] Embodiment 1: It is 300mg / L for COD, and the sewage that contains total nitrogen is 48mg / L carries out filtration test. The sewage inflow is 10L / h, and the density of the polyester sponge in the filter column is 0.022g / cm 3 , the height is 60cm, the porosity when it is loose is 85%, and the sponge compression ratio is 75% for compression and filtration during operation. The COD removal rate of the final sewage can reach more than 80%, and the highest can reach 90%. The removal rate of nitrogen was 50%.

Embodiment 2

[0009] Example 2: Filtration test was carried out on sewage with turbidity of 200 NTU added with kaolin. The flow rate of the sewage inflow is 20L / h, and the density of the polyester sponge in the filter column is 0.022g / cm 3 , the height is 60cm, the porosity when loose is 85%, and the compressive filtration is carried out under the condition that the sponge compression ratio is 75% during operation, and the average removal of turbidity by the final sponge filter material is 93.9%. The running time for treating sewage with a turbidity of 200NTU is 60 hours. When the influent turbidity is 50NTU and 20NTU, the average removal rate of turbidity by the sponge filter material is 92.2% and 85.5% respectively.

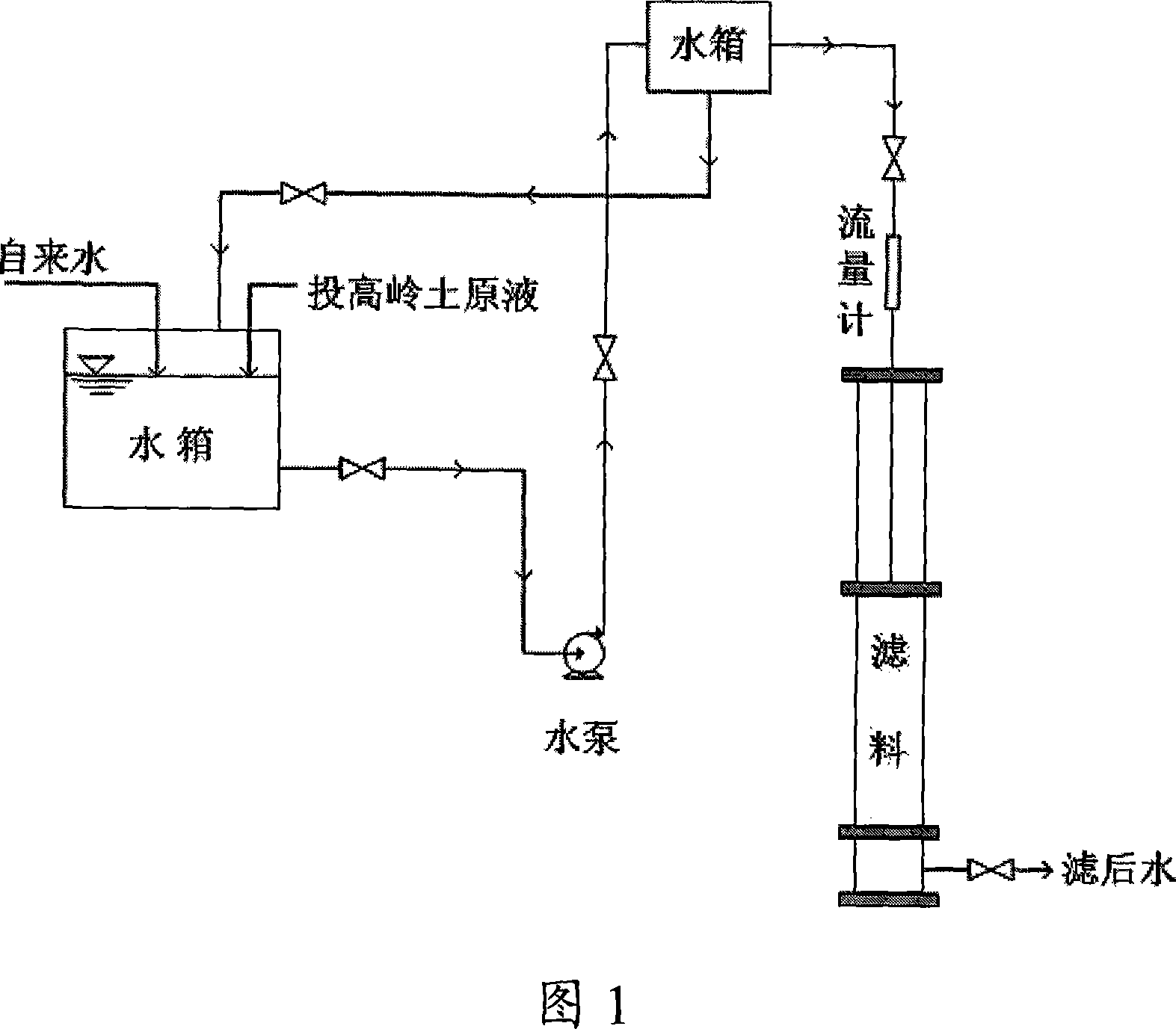

[0010] A simple flow chart of the filter column with a press plate of the present invention can be referred to in Figure 1 of the accompanying drawings.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com