Method for purifying capsicine compound from capsicol resin by using ammoniacal liquor

A technology for capsicum oleoresin and capsaicin, which is applied in the field of extraction of capsaicinoid compounds, can solve the problems of difficult recycling of alkali metal salts, increase the burden of waste liquid treatment, unfavorable purification steps, etc., and achieves easy large-scale production and production cost. Low, inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

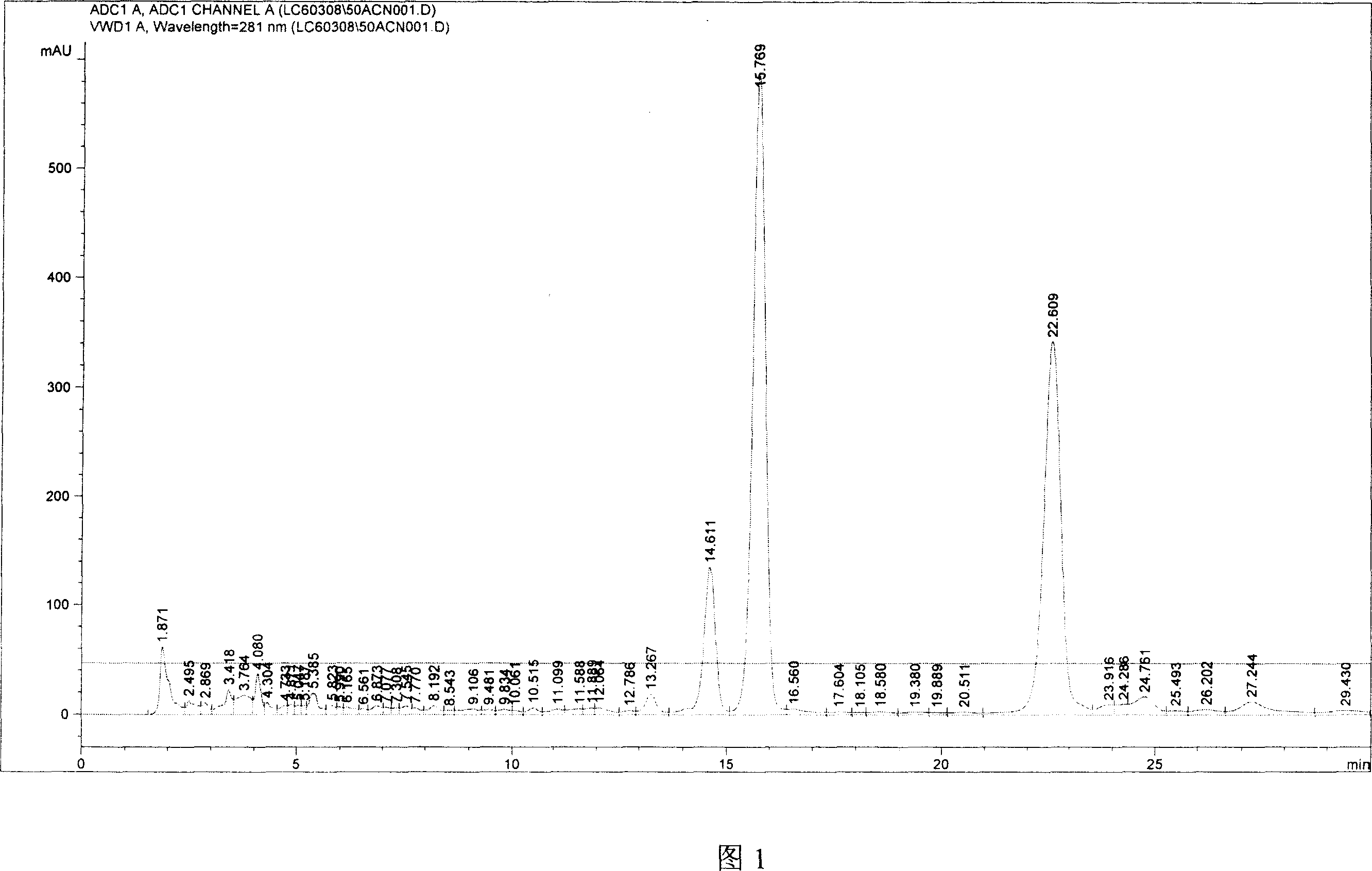

[0024] Get capsaicin content and account for 0.5% capsicum oleoresin 2g of gross weight, add 50ml 25% concentrated ammonia water, react in autoclave, the pressure in autoclave is 13.5atm, and temperature is 90 ℃, and reaction time 10min. The extract was distilled at 70°C. The distilled extract was titrated with hydrochloric acid to pH=4, extracted with 50 ml of n-hexane, centrifuged for 5 min to separate the organic phase, concentrated under reduced pressure to recover n-hexane to obtain a concentrated solution. Add 10ml of diethyl ether to the concentrated solution, freeze and crystallize at -10°C, and obtain 13.8 mg of capsaicin compound crystals, which are detected by high performance liquid chromatography and contain: 52.8% capsaicin, 38.2% dihydrocapsaicin, and 38.2% capsaicin nordihydrocapsaicin Alkali 6%. It can be seen that the content of the obtained capsaicin is: 7.29mg, and its yield is: 72.9%.

Embodiment 2

[0026] Get capsaicin content and account for the capsicum oleoresin 2g of gross weight 0.5%, add 30ml 25% concentrated ammonia water, react in autoclave, the pressure in autoclave is 5atm, and temperature is 70 ℃, and reaction times 1 hour. The extract was distilled at 70°C. The extract after the ammonia gas was evaporated was titrated with hydrochloric acid to pH = 7, extracted twice with 50 ml of n-hexane, left to stand for 0.5 hour, concentrated under reduced pressure to recover n-hexane to obtain a concentrated solution. Add 10ml of diethyl ether to the concentrated solution, freeze and crystallize at -10°C, and obtain 15.1 mg of capsaicin compound crystals. After detection by high performance liquid chromatography, the obtained crystals contain: capsaicin 51.4%, dihydrocapsaicin 37.3%, nordihydrocapsaicin Capsaicin 7.1%. It can be seen that the content of the obtained capsaicin is: 7.25mg, and its yield is: 72.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com