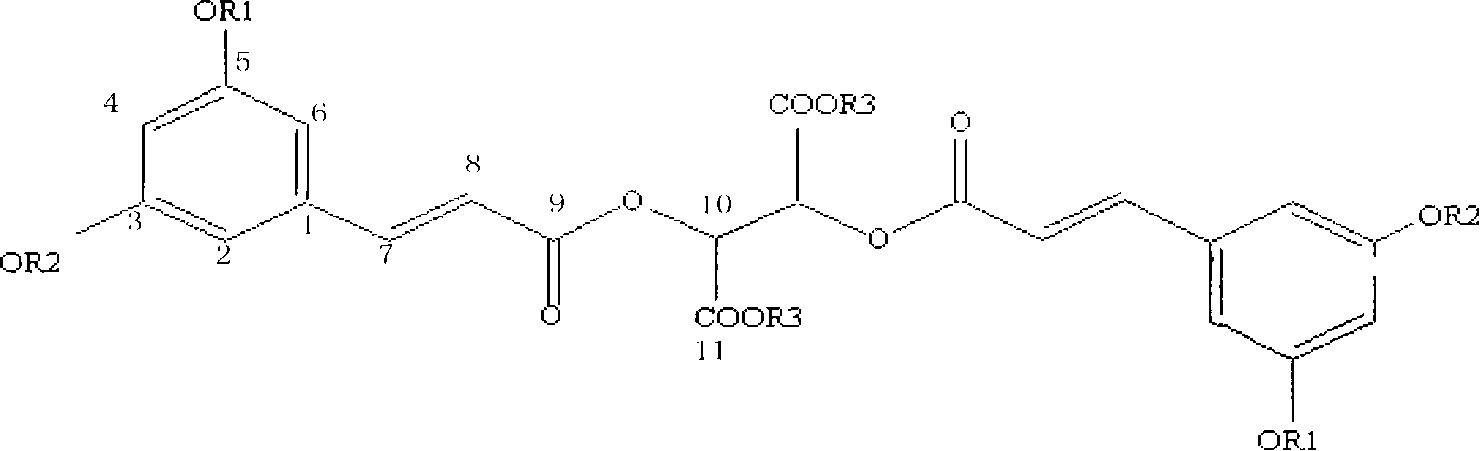

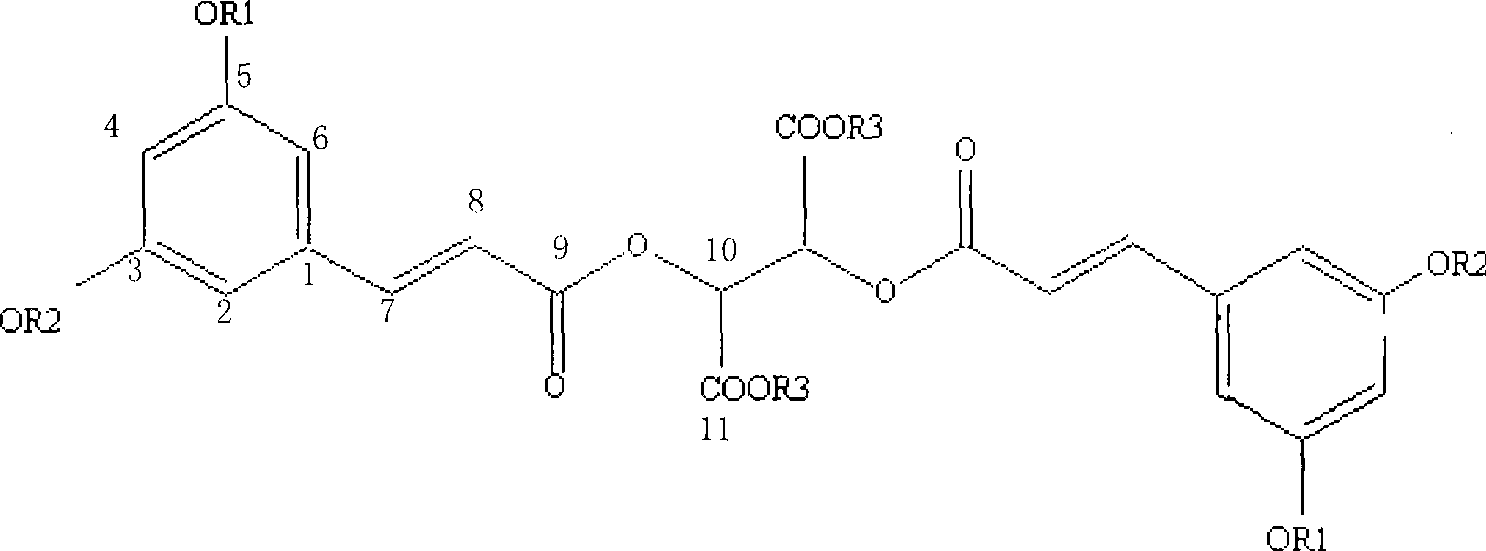

Iso chicoric acid and extraction separation method thereof and usage in medicament

A water extraction, Compositae plant technology, applied in the field of extraction and separation of effective parts of traditional Chinese medicine and medical applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Preparation of Di-3,5 Dihydroxycinnamoyl Tartaric Acid

[0069] Take 100kg of the medicinal material Amulinia acuminata, add 15 times the amount of water, decoct twice for 2 hours each time, combine the filtrate, concentrate to contain 10 grams of medicinal material per ml, add ethanol to the alcohol concentration of 60%, centrifuge, and supernatant 10% calcium oxide milk was added to the solution to adjust the pH to 8-9, and 10 kg of precipitate was obtained. The precipitate was suspended in 90% ethanol, adjusted to pH = 3 with sulfuric acid, and centrifuged. The alcohol solution was adjusted to pH = 5 with 40% sodium hydroxide solution. -6. Centrifuge, recover ethanol, add water to dilute to a concentration of 10g of crude drug per ml, pass through the treated polyamide column, elute with distilled water and 60% ethanol successively, collect each part of the eluate, and concentrate the water eluate appropriately , extracted with ethyl acetate, discarded the ethyl acet...

Embodiment 2

[0071] Preparation of Di-3,5 Dihydroxycinnamoyl Tartaric Acid

[0072] Take 100kg of the medicinal material Amulinia acuminata, add 10 times the amount of water, decoct twice for 1.5 hours each time, combine the filtrates, concentrate to contain 20 grams of medicinal materials per ml, add ethanol until the alcohol concentration is 700%, centrifuge, and supernatant Add 10% calcium oxide milk to the solution to adjust the pH to 9-10, obtain 12 kg of precipitate, centrifuge, adjust the pH of the alcoholic solution to 6-7 with 40% sodium hydroxide solution, centrifuge, recover ethanol, add water to dilute to contain 10 g of crude drug per ml Through the treated macroporous resin column, elute with distilled water and 60% ethanol successively, collect the water eluate, concentrate it properly, precipitate the concentrated solution with acetone, dissolve the precipitate with water, add methanol for precipitation, and dissolve the precipitate with water Recrystallized with methanol t...

Embodiment 3

[0074] Preparation of Di-3,5 Dihydroxycinnamoyl Tartaric Acid

[0075] Take 100kg of the medicinal material Amulinia acuminosa, add 20 times the amount of water, decoct 3 times, 2 hours each time, combine the filtrate, concentrate to contain 10 grams of medicinal material per ml, add ethanol to the alcohol concentration of 80%, centrifuge, and supernatant Add 10% calcium oxide milk to the liquid to adjust to PH=10-12, obtain 8kg of precipitate, centrifuge, adjust pH=6-7 with 40% sodium hydroxide solution, centrifuge, reclaim ethanol, add water to dilute to contain 15g crude drug per ml concentration, mixed into silica gel, packed into a column, developing agent: n-butanol: acetic acid: water = 70:35:10, developed, cut and collected according to the color band, dissolved in methanol, and recrystallized repeatedly with water and methanol to obtain More than 80% di-3,5 dihydroxycinnamoyl tartaric acid compound 360mg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com