Permanently excited synchronous machine comprising suppression means for improving torque irregularities

A synchronous motor and permanent magnet technology, applied in synchronous motors with stationary armatures and rotating magnets, electric components, electromechanical devices, etc., can solve the problems of torque fluctuation, reduce torque fluctuation, etc., to suppress torque fluctuation stability, low stray field, easy alignment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

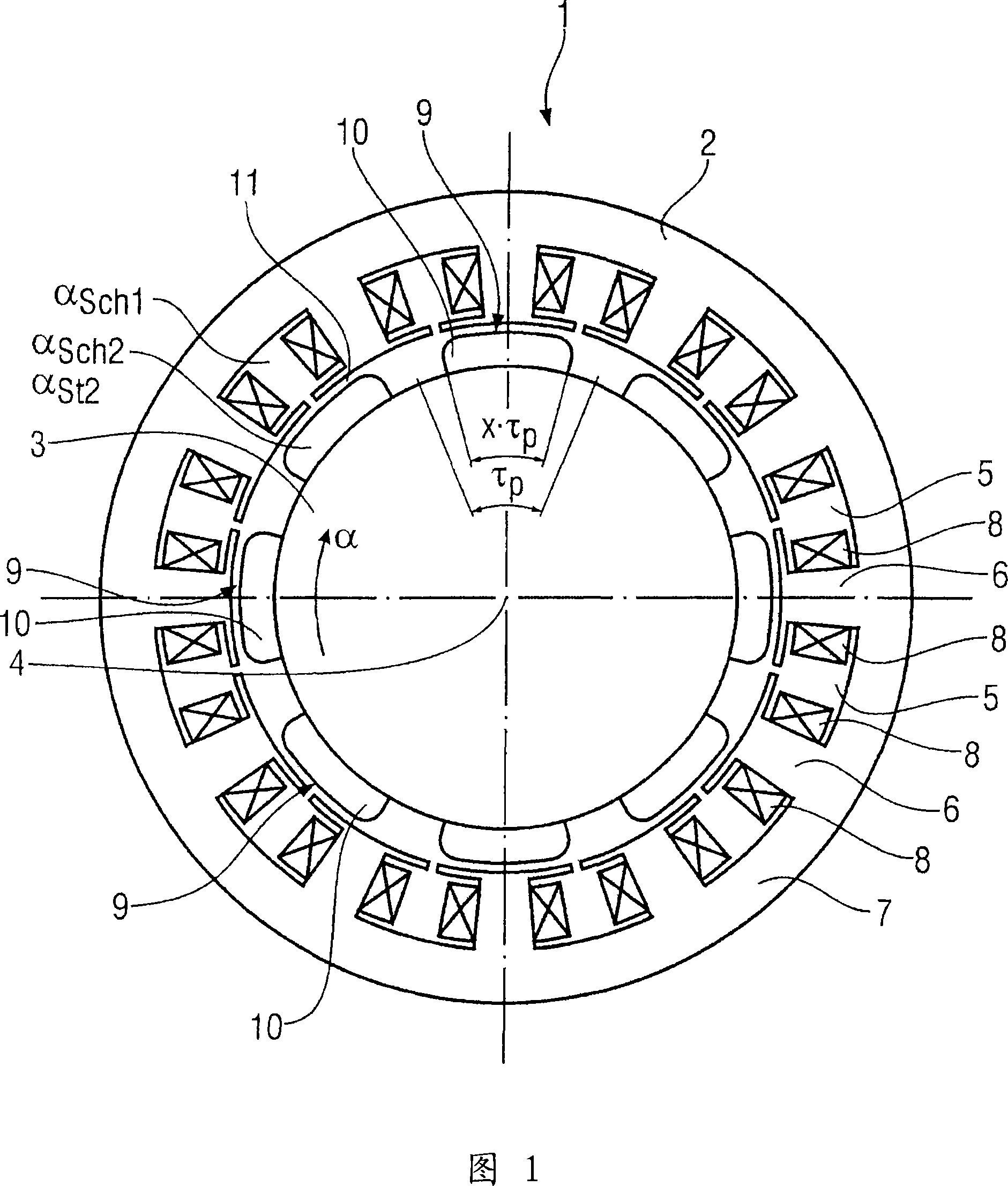

[0028] FIG. 1 shows a permanent-magnet-excited synchronous motor designed as a motor in cross-section. It contains a stator 2 and a rotor 3 mounted rotatably about an axis of rotation 4 . The rotor 3 is an inner rotor. On its inner wall facing the rotor 3 , the stator 2 comprises a plurality of, in the exemplary embodiment of FIG. 1 , a total of twelve slots 5 uniformly distributed around the circumference, between which teeth 6 are formed. The outer ring yoke 7 connects the teeth 6 to one another. The tooth winding coils 8 each surrounding a tooth 6 are arranged in the slot 5 . The rotor 3 is provided with permanent magnets 9 which are arranged so that a total of eight magnetic poles 10 are evenly spaced around the circumference. Here, each magnetic pole 10 corresponds to a pole pitch τ formed by the angular range of the circumferential angle α P . The permanent magnet 9 is not along the pole pitch τ in the circumferential direction P extends over the entire angular ran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com