Metal porphyrin langmuir blodgett film optical fiber gas sensor

A gas sensor and metalloporphyrin technology, which is used in instruments, scientific instruments, material analysis by optical means, etc., can solve the problems of detection accuracy affecting the promotion and application of sensors, poor selective recognition ability, and insufficient sensitivity. Selectivity of sensitive substances, precise thickness control, good film formation uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

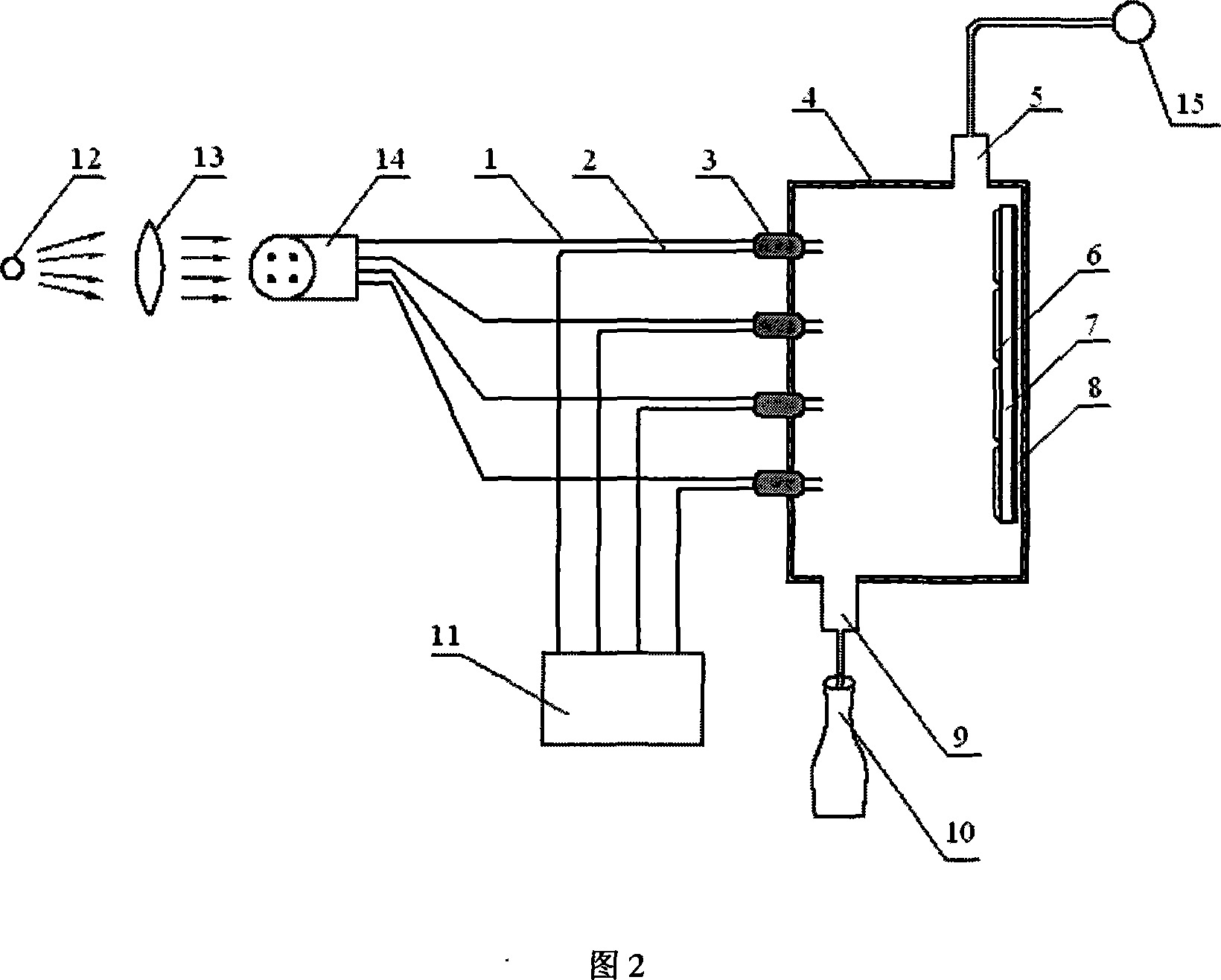

[0026] As shown in Figure 1, a metalloporphyrin Langmuir-Brodite membrane optical fiber gas sensor mainly includes 4 groups of double-arm optical fibers, 4 reaction chambers, and a metalloporphyrin LB membrane array plate. The metalloporphyrin LB film array plate consists of a metalloporphyrin LB film array 6 , a substrate 7 and a mirror 8 . The optical fiber is a general optical fiber, and the incident optical fiber 1 and the outgoing optical fiber 2 have the same hole diameter. Each group of double-armed optical fibers is composed of an incident optical fiber 1, an outgoing optical fiber 2 and an optical fiber probe 3. The other end of the optical fiber probe 3 is left The incident and outgoing fiber optic heads are fixed in the fiber optic probe at the same angle and symmetrical to each other, and the optical path direction of the remaining part of the incident and outgoing fiber optic heads should point to the corresponding metal porphyrin of the group of double-armed fiber...

Embodiment 2

[0028] A metalloporphyrin Langmuir-Brodite membrane optical fiber gas sensor mainly includes 2 groups of double-armed optical fibers, 4 reaction chambers, and a metalloporphyrin LB membrane array plate. The metalloporphyrin LB film array plate consists of a metalloporphyrin LB film array 6 , a substrate 7 and a mirror 8 . The optical fiber is a general optical fiber, and the incident optical fiber 1 and the outgoing optical fiber 2 have the same hole diameter. Each group of double-armed optical fibers is composed of an incident optical fiber 1, an outgoing optical fiber 2 and an optical fiber probe 3. The other end of the optical fiber probe 3 is left The incident and outgoing fiber optic heads are fixed in the fiber optic probe at the same angle and symmetrical to each other, and the optical path direction of the remaining part of the incident and outgoing fiber optic heads should point to the corresponding metal porphyrin of the group of double-armed fibers. The central poin...

Embodiment 3

[0030] A metalloporphyrin Langmuir-Brodite membrane optical fiber gas sensor mainly includes 6 groups of dual-arm optical fibers, 4 reaction chambers, and a metalloporphyrin LB membrane array plate. The metalloporphyrin LB film array plate consists of a metalloporphyrin LB film array 6 , a substrate 7 and a mirror 8 . The optical fiber is a general optical fiber, and the incident optical fiber 1 and the outgoing optical fiber 2 have the same hole diameter. Each group of double-armed optical fibers is composed of an incident optical fiber 1, an outgoing optical fiber 2 and an optical fiber probe 3. The other end of the optical fiber probe 3 is left The incident and outgoing fiber optic heads are fixed in the fiber optic probe at the same angle and symmetrical to each other, and the optical path direction of the remaining part of the incident and outgoing fiber optic heads should point to the corresponding metal porphyrin of the group of double-armed fibers. The central point of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com