Method of preparing high rare-earth content magnesium intermediate alloy

A technology of high rare earth content and master alloy, which is applied in the field of preparation of rare earth magnesium master alloy, which can solve the problems of low current efficiency, rare earth metal yield, low product purity, uneven rare earth content, and complex structure of the electrolytic cell, so as to improve the metal yield And current efficiency and product quality, high rare earth content, suitable for large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

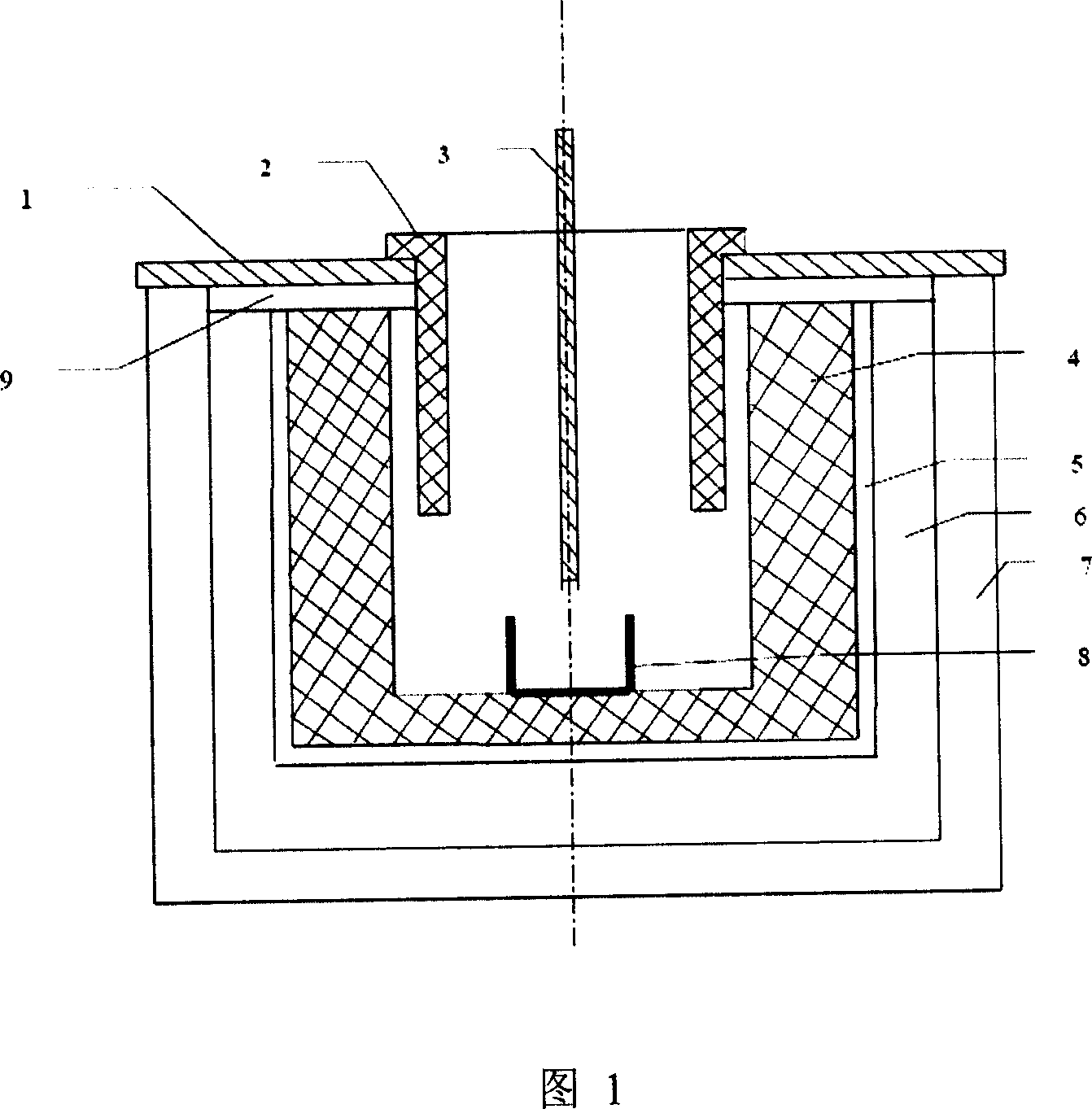

Method used

Image

Examples

example 1

[0018] 1. Electrolyte ratio YF 3 : LiF=90:10, the mixture feeding ratio is Y 2 o 3 :MgO=84:16, electrolysis temperature 1000~1020℃: current intensity is 2200A, cathode current density is 20A / cm 2 , the electrolysis time is 1 hour, and the amount of the mixture added is 2kg. 1.43 kg of alloy was obtained, the content of yttrium in the alloy was 84.6%, and the current efficiency was 71.7%. The alloy composition analysis results are shown in the table below:

[0019] Y

Embodiment 2

[0021] Electrolyte ratio NdF 3 :MgF 2 : LiF=85%: 5%: 10%, the mixture feeding ratio is Nd 2 o 3 :MgO=80:20, electrolysis temperature 920~950℃: current intensity is 1500A, cathode current density is 12A / cm 2 , the electrolysis time is 1 hour, and the amount of the mixture added is 2.1kg. 1.56kg of alloy was obtained, the Nd content in the alloy was 90.6%, and the current efficiency was 74%. The alloy element analysis is shown in the table below.

[0022] Nb

Embodiment 3

[0024] Electrolyte ratio GdF 3 : LiF=90:10, the mixture feeding ratio is Gd 2 o 3 :MgO=80:20, electrolysis temperature 1000~1020℃: current intensity is 2200A, cathode current density is 20A / cm 2 , The continuous electrolysis time is 48 hours, and the amount of the mixture added is 159.5kg. 114.23 kg of alloy was obtained, the total amount of gadolinium contained in the alloy was 103.26 kg, the current efficiency was 72.9%, and the yield of metal gadolinium was 93.3%. The alloy element analysis is shown in the table below.

[0025] Gd

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com