Multiple resonance tube thermo-acoustic engine

A thermoacoustic engine, multi-resonance technology, applied to machines/engines, mechanisms that generate mechanical power, compressors, etc., can solve problems such as engine operating frequency jumps, restricting the process of practicality, and the inability of resonant tubes to play a role, reducing Viscous flow loss, improving heat-to-power conversion efficiency, and suppressing nonlinear effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

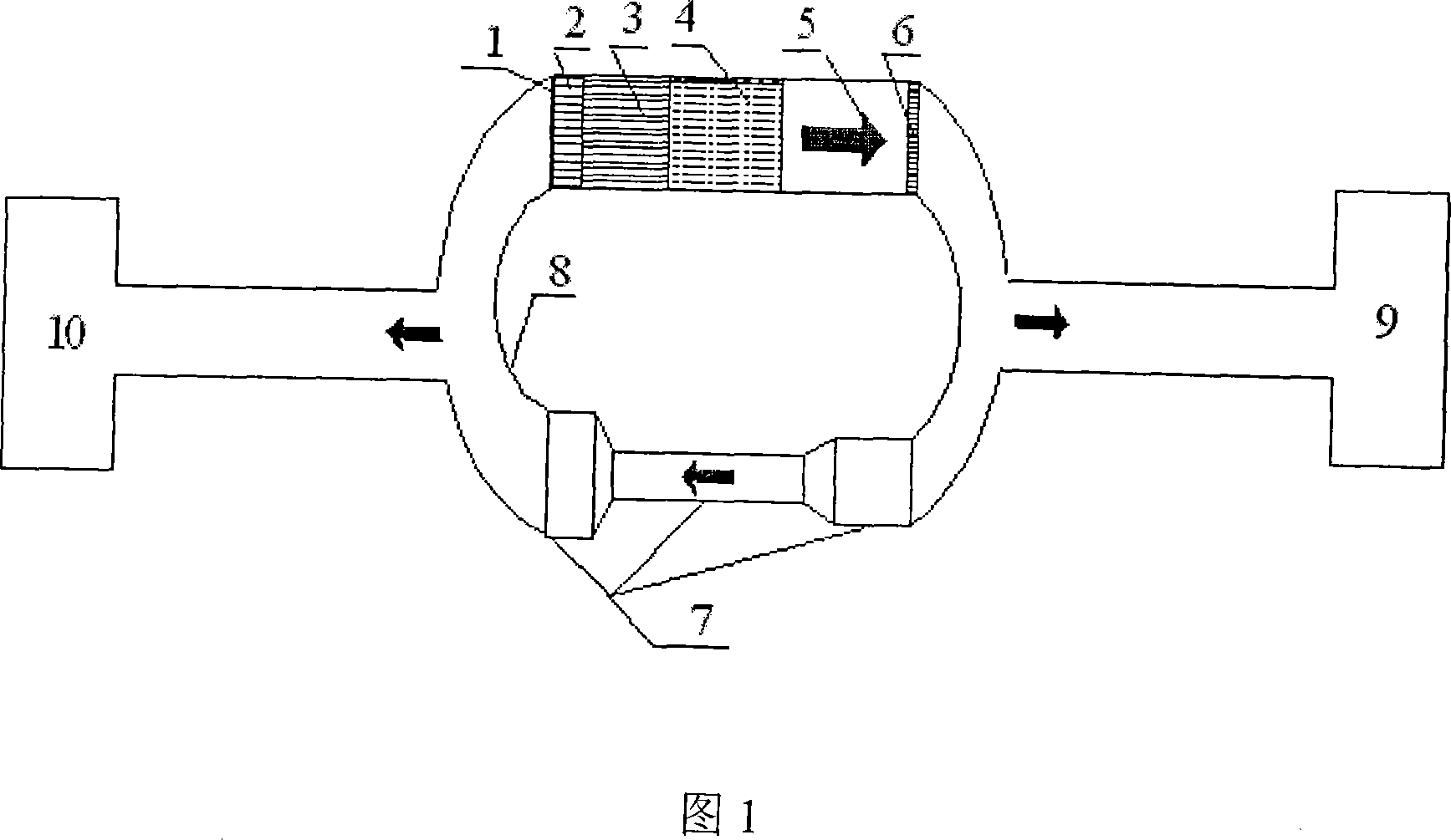

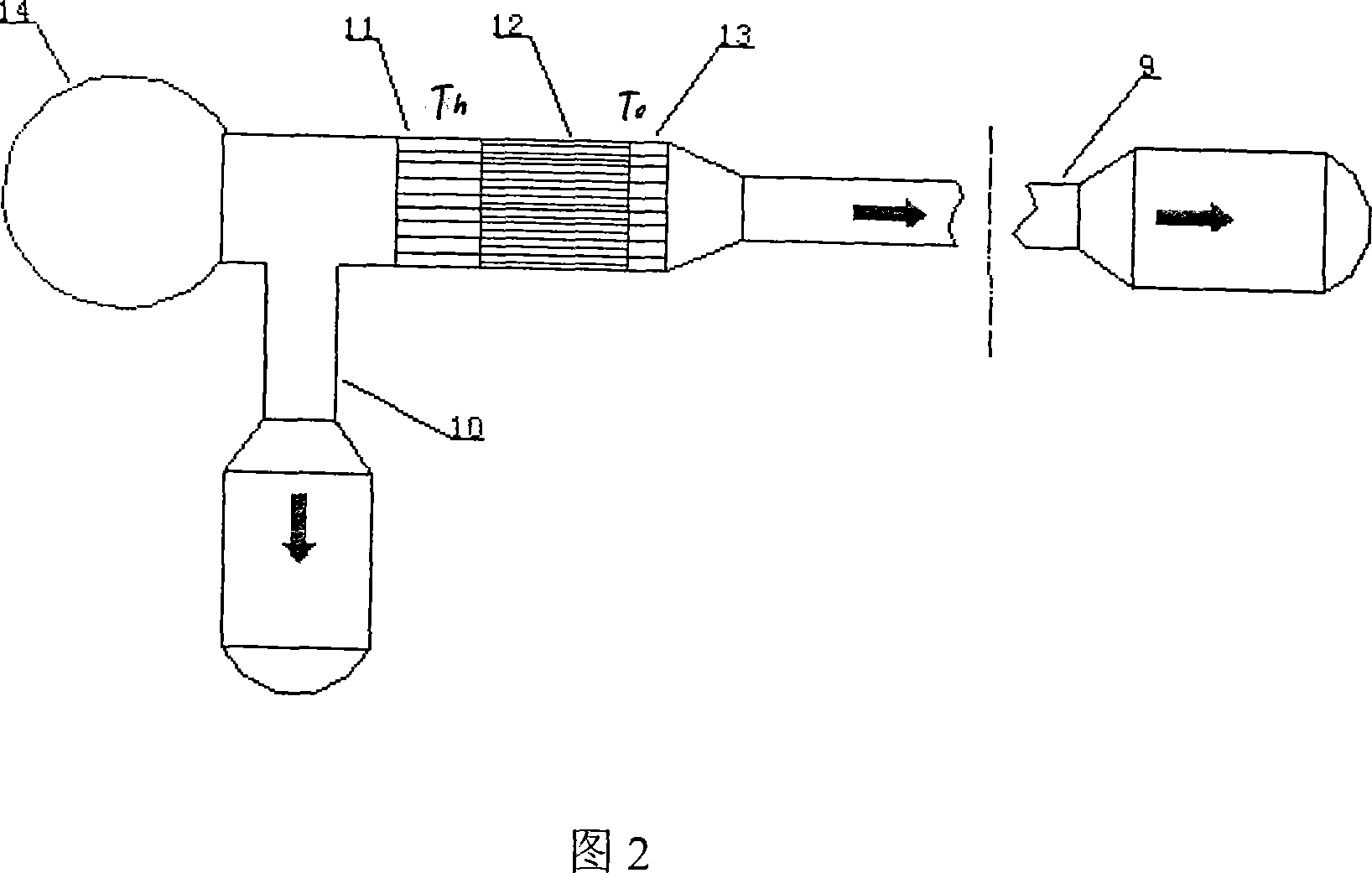

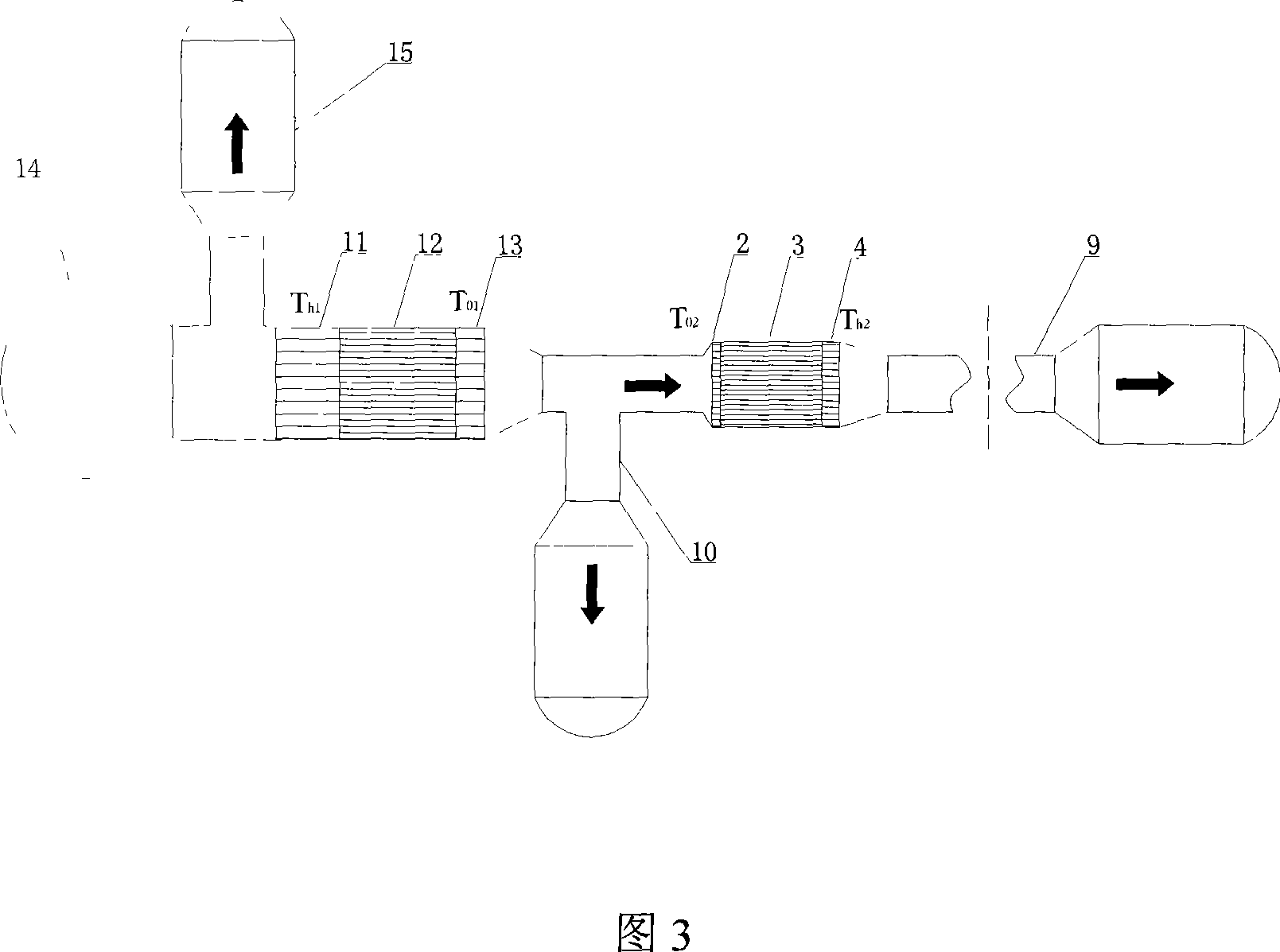

[0020] The resonant tube of a thermoacoustic engine is usually a straight tube with a specific inner diameter. In order to realize the 1 / 4 wavelength sound field condition, an air reservoir is often set at the end of the straight tube. The single resonant tube traveling wave thermoacoustic engine has a traveling wave loop and a straight resonant path, and an air reservoir is arranged at the end of the resonant tube. The engine has a main cooler, a regenerator, a heater, a heat buffer pipe, a feedback loop, a sound capacity, and a DC suppression component connected in sequence, and the resonance pipe is drawn out from the tee. The single resonant tube standing wave thermoacoustic engine has a high-temperature cavity, a hot-end heat exchanger, a thermoacoustic plate stack, and a cold-end heat exchanger connected in sequence. The resonant tube is connected to the cold-end heat exchanger through a pipe diameter transition tube. An air reservoir is also arranged at the end, and par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com