Method of synthesizing monodisperse micron-level poly(methyl methacrylate) micro-sphere

A technology of polymethyl methacrylate and methyl methacrylate, which is applied in the field of preparation of functional polymer materials, can solve problems such as poor repeatability of the method, poor affinity of polar molecules, and the uniformity of microspheres that cannot meet practical requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

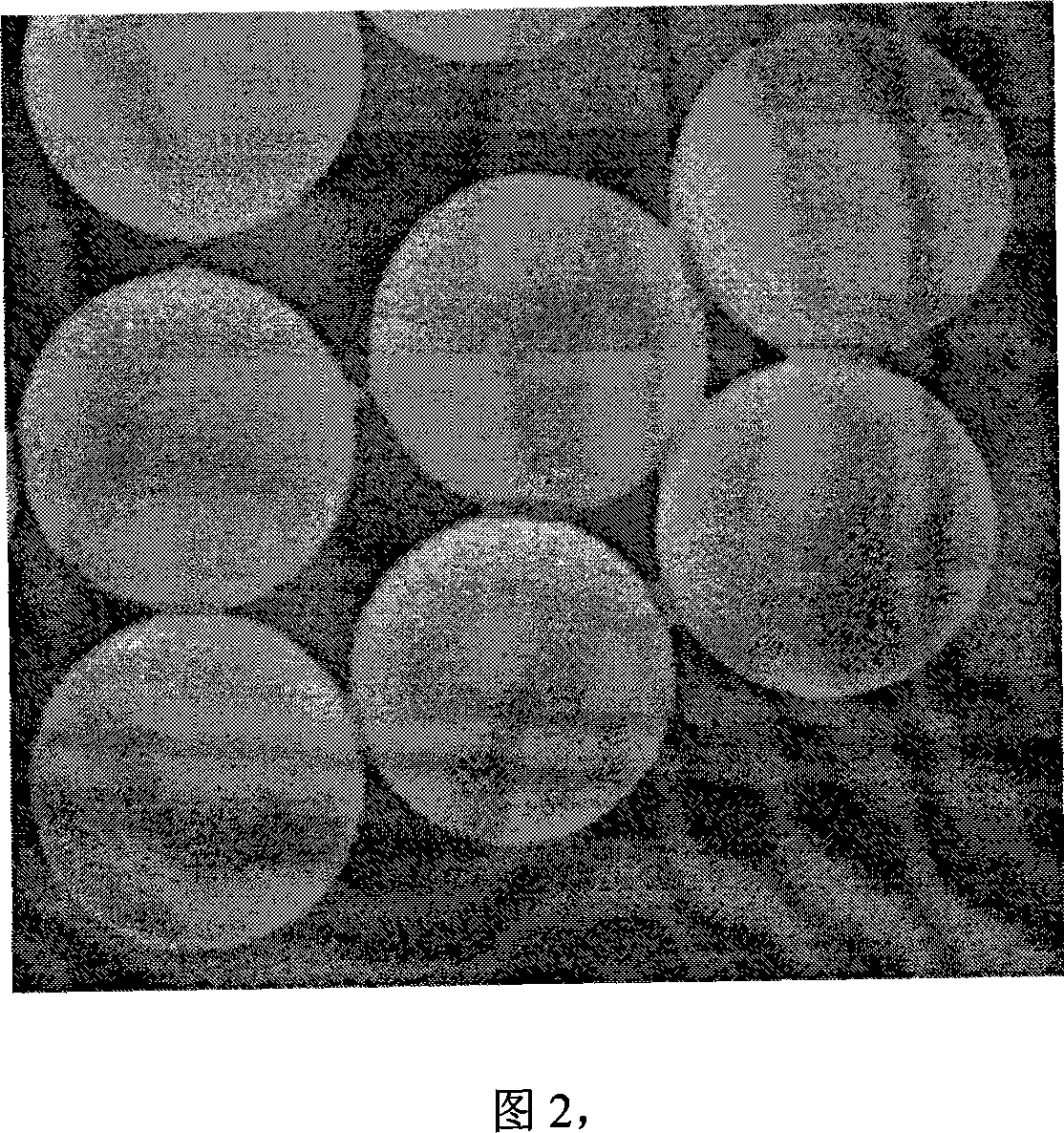

Image

Examples

Embodiment 1

[0028] Example 1: Dissolve 1.5g of PVPK-30 in 25.0g of methanol, transfer to a 100ml glass container, then add 2.5g of MMA containing 75mgAIBN, pass N 2 10 minutes, put into stirring bar then, seal container opening, be placed on the magnetic stirrer with the speed of 60rpm and stir evenly, maintain this rotating speed in the whole reaction process. The temperature was raised at a rate of 12.5°C / hour, finally stabilized at 50°C, and reacted for 18 hours. After the reaction was completed, it was centrifuged / redispersed and washed 4 times with methanol, and vacuum-dried at room temperature. The average particle size is 3.67 μm, and the product number particle size distribution CV is 3.21%.

Embodiment 2

[0029] Embodiment 2: the PVP K-30 of 0.5g is dissolved in the ethanol of 25.0g, transfers in the glass container of 100ml, adds in the MMA of 2.5g containing 150mg AIBN again, passes N 2 10 minutes, put into stirring bar then, seal container opening, be placed on the magnetic stirrer with the speed of 60rpm and stir evenly, maintain this rotating speed in the whole reaction process. The temperature was raised at a rate of 5°C / hour, and finally stabilized at 40°C, and reacted for 18 hours. After the reaction was completed, it was centrifuged / redispersed and washed 4 times with methanol, and vacuum-dried at room temperature. The average particle size is 2.83 μm, and the product number particle size distribution CV is 4.37%.

Embodiment 3

[0030] Example 3: Dissolve 1.5g of PVPK-30 in 25.0g of methanol, transfer to a 100ml glass container, then add 2.5g of MMA containing 12.5mgAIBN, pass N 2 10 minutes, put into stirring bar then, seal container opening, be placed on the magnetic stirrer with the speed of 60rpm and stir evenly, maintain this rotating speed in the whole reaction process. The temperature was raised at a rate of 10°C / hour, finally stabilized at 55°C, and reacted for 18 hours. After the reaction was completed, it was centrifuged / redispersed and washed 4 times with methanol, and vacuum-dried at room temperature. The average particle size is 4.01 μm, and the product number particle size distribution CV is 2.88%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com