Lithium borohydride hydrogen storage material decorated by oxide and preparation method thereof

A hydrogen storage material, lithium borohydride technology, applied in the direction of chemical instruments and methods, borane/diborane hydride, other chemical processes, etc., can solve the problems that are difficult to meet the practical application of alloys, and achieve a simple and efficient method. The effect of hydrogen temperature reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

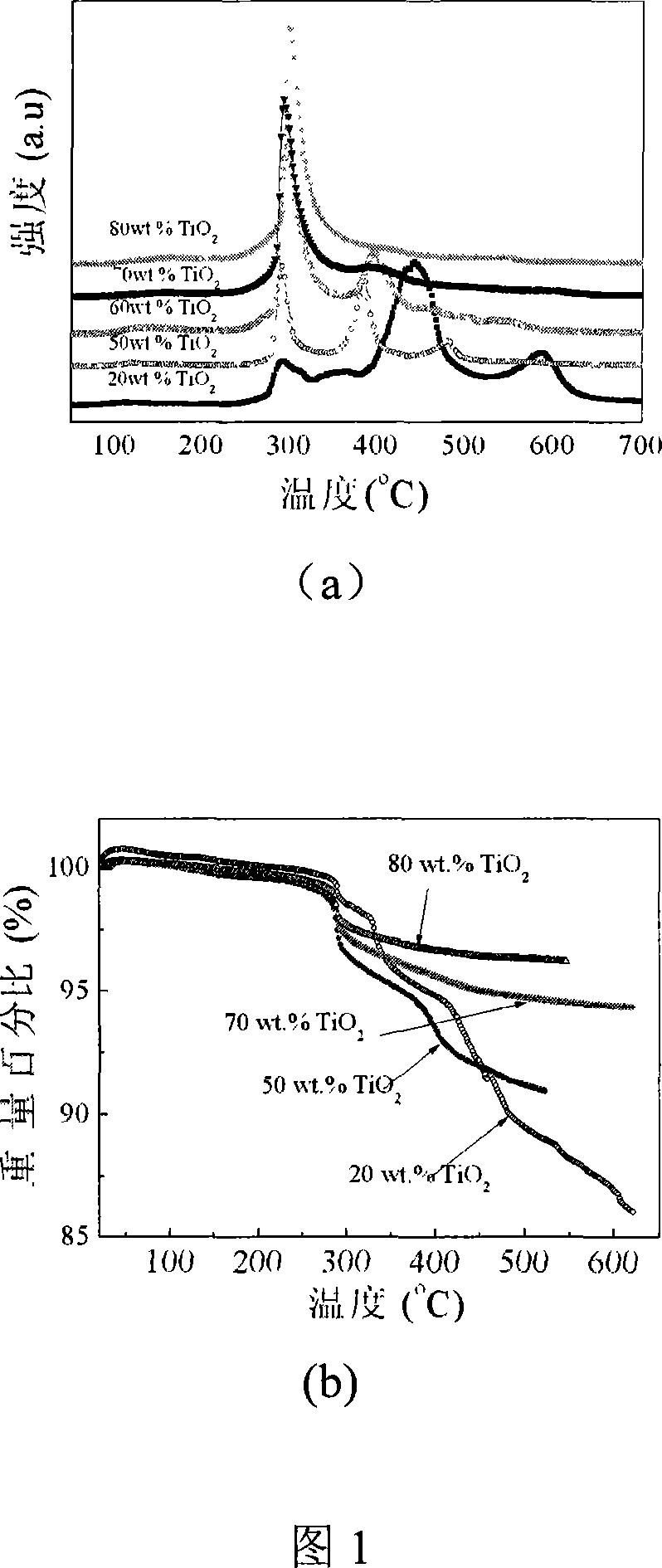

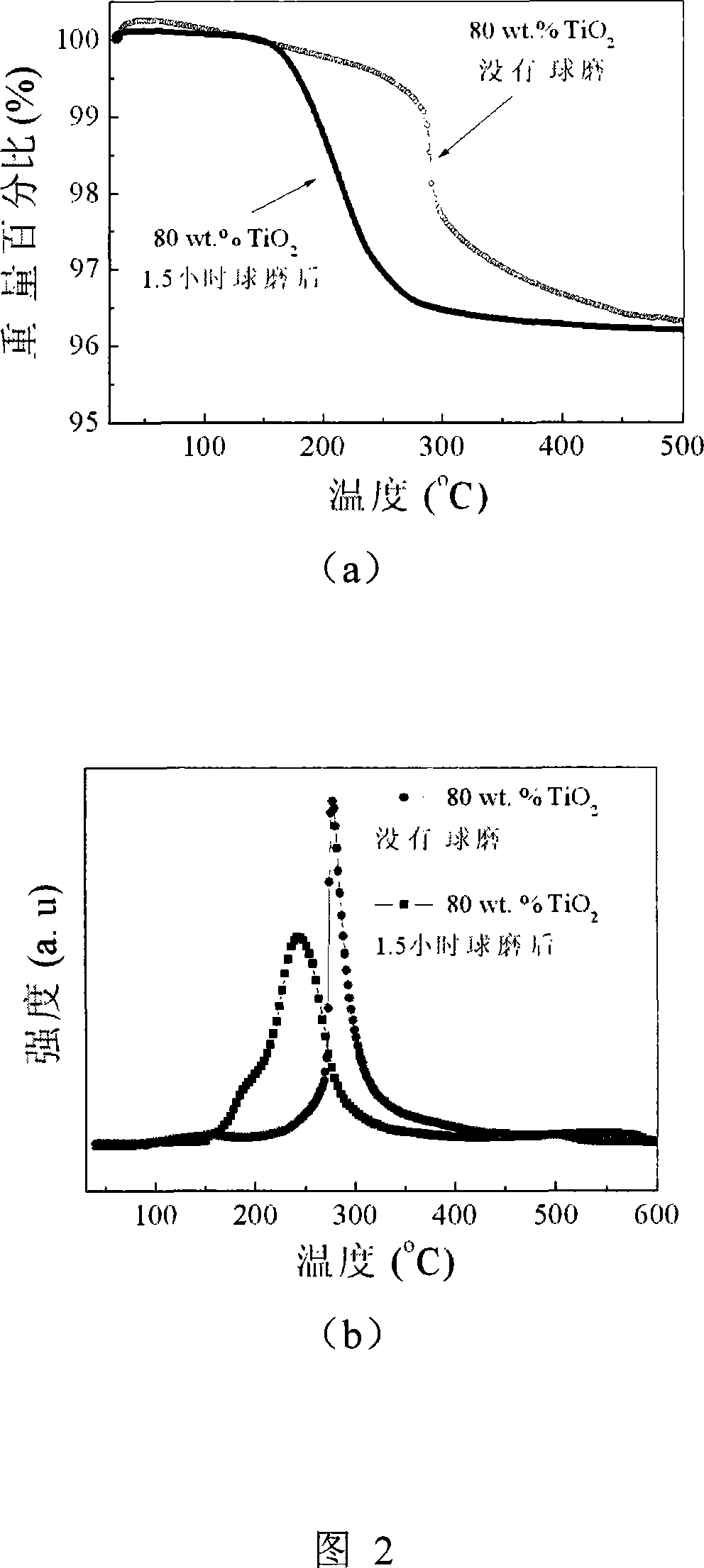

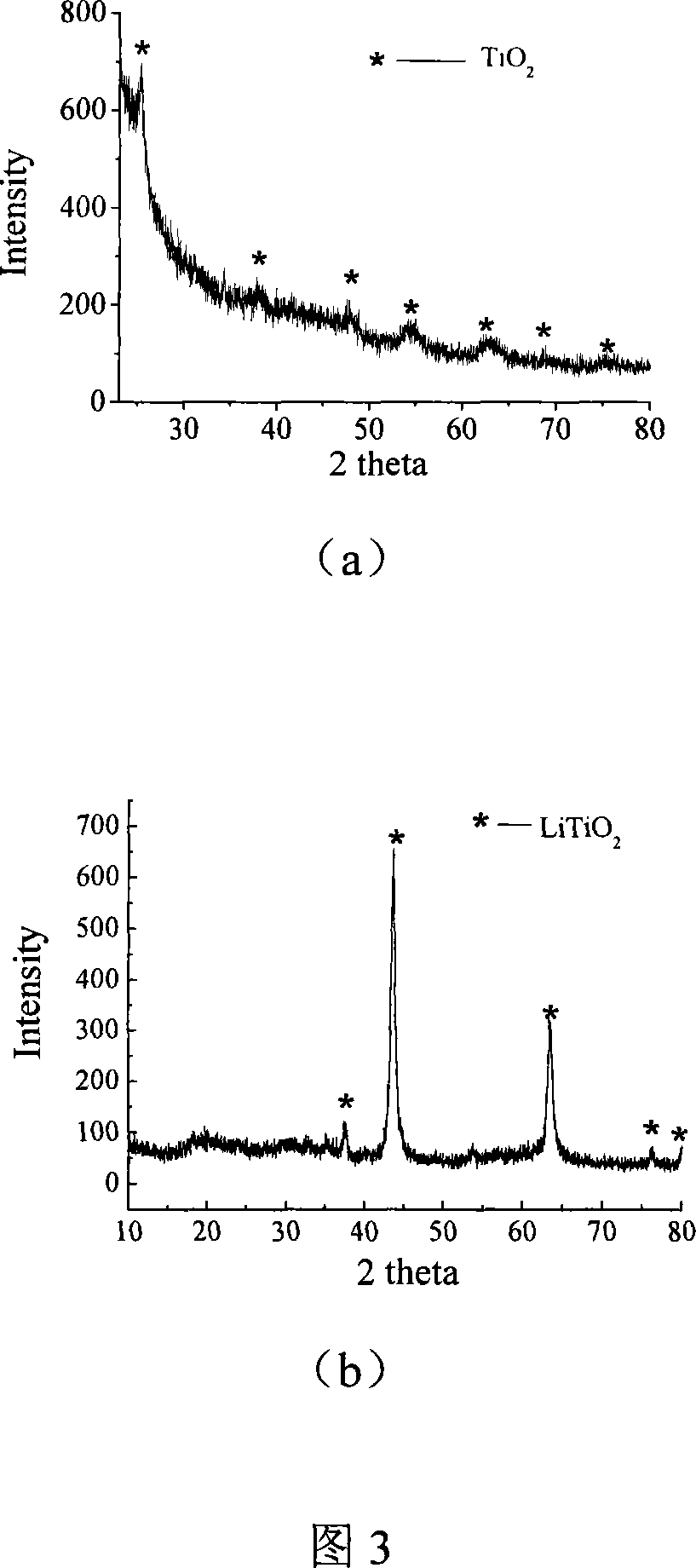

[0019] LiBH 4 For commercial purchase, TiO 2 Prepared by sol-gel method (H. Choi, E. Statathos, D.D. Dionysiou, Applied Catalysis B-Environmental 2006, 63, 60-67.). LiBH 4 and different mass percentages of TiO 2 (20%-80%) are mixed and ball milled in a stainless steel vessel for 5 minutes under the protection of an inert atmosphere. Figure 1 is LiBH 4 and different TiO 2 Mass spectrometry (a) and thermogravimetric (b) analysis results after mixing. It can be seen that after TiO 2 Modified LiBH 4 The dehydrogenation temperature was significantly lowered. Further, with 80wt% TiO 2 After 1.5 hours of ball milling, LiBH 4 The initial dehydrogenation temperature was reduced to around 150 °C (Fig. 2). From the XRD results, it can be seen that LiBH after dehydrogenation 4 +TiO 2 The reaction yielded a new product, LiTiO 2 , reduce LiBH 4 Root cause of hydrogen desorption temperature.

Embodiment 2

[0021] LiBH 4 and ZrO 2 For commercial purchase, TiO 2 ,TiO 2 -SiO 2 and Al 2 o 3 -SiO 2 Prepared by sol-gel method. LiBH 4 Mix with 50% of the different oxides and grind in an agate vessel for 5 minutes. Figure 4 shows the mass spectrometry results of these mixtures. It can be seen that the LiBH modified by different oxides 4 The dehydrogenation temperature was significantly lowered.

Embodiment 3

[0023] LiBH 4 and Fe 2 o 3 Purchased for business. 50wt%LiBH 4 and 50wt% Fe 2 o 3 After mixing, ball milling was carried out for different time respectively. Fig. 5 is the mass spectrometry analysis result of the mixture of different ball milling times. It can be seen that after Fe 2 o 3 Modified LiBH 4 The dehydrogenation temperature was significantly lowered. Especially ball milled for 4 hours, 50wt% LiBH at 150°C 4 +50wt%Fe 2 o 3The initial hydrogen desorption temperature of the components is reduced to about 150°C, and most of the hydrogen can be released below 250°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com