Segmented calcium and sodium double alkali method desulfurizing technology and device thereof

A desulfurization process and dual-alkali process technology, which is applied in the field of segmented sodium-calcium dual-alkali process desulfurization process and its devices, can solve the problems of water in the flue gas, low desulfurization efficiency, shortened service life of mist eliminators, etc. The effect of blocking dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

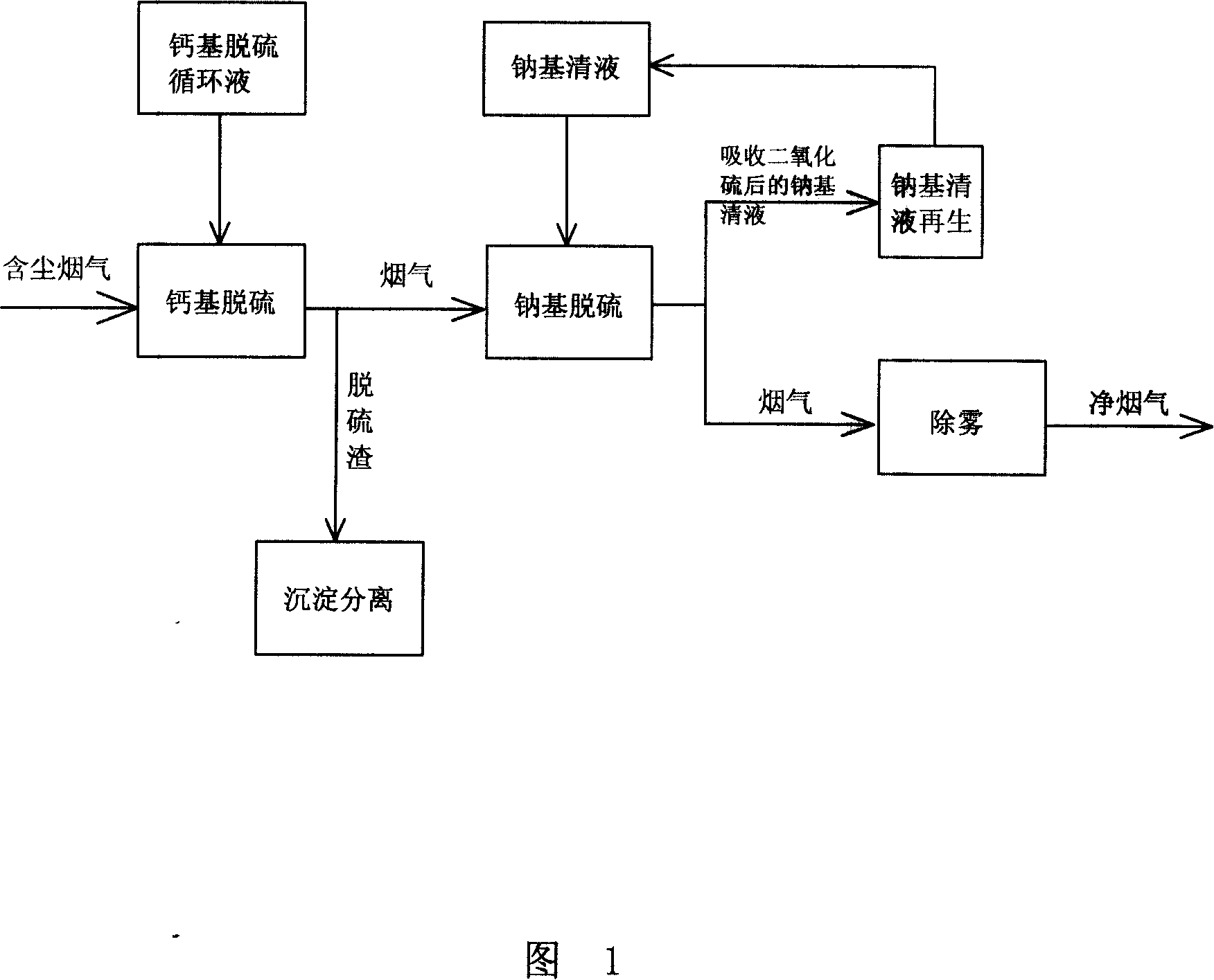

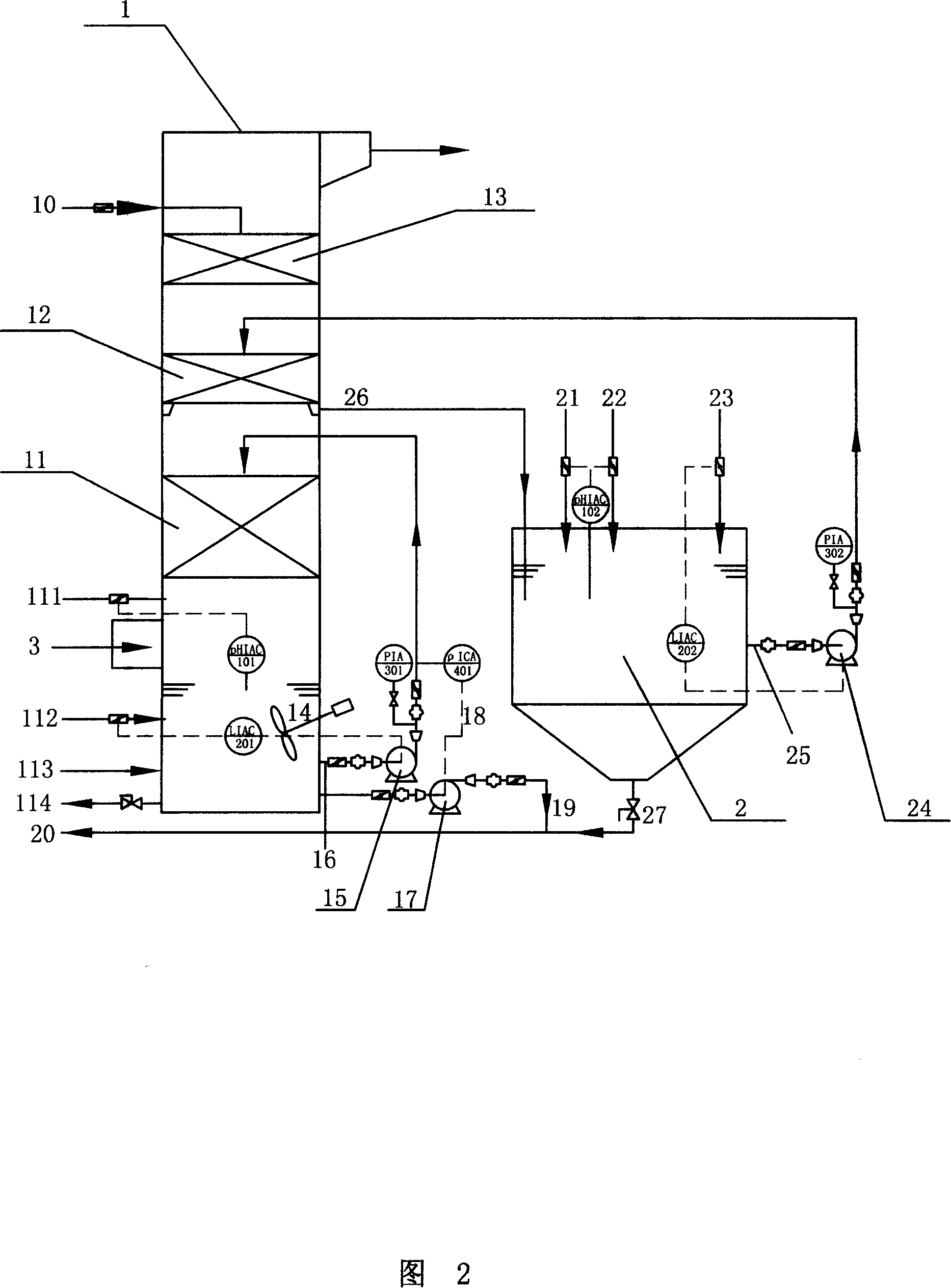

[0041]As shown in Figure 1, a segmented sodium-calcium double-alkali desulfurization process sends the dust-laden flue gas into the absorption tower for calcium-based desulfurization first, and the flue gas is washed by calcium-based desulfurization circulating liquid prepared from lime or limestone Perform desulfurization to remove most of the soot and SO in the flue gas 2 and some oxygen;

[0042] After calcium-based desulfurization, the flue gas is then subjected to sodium-based desulfurization, and further desulfurized by washing with sodium-alkali or sodium-alkali clear liquid regenerated from calcium-alkali to remove trace amounts of sulfur dioxide in the flue gas;

[0043] The clean flue gas obtained after calcium-based desulfurization and sodium-based desulfurization is discharged after demisting.

[0044] The calcium-based desulfurization circulating fluid used for desulfurization returns to the bottom of the absorption tower, and after being mixed with fresh calcium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com