Method and device for designing linear laser three dimension scanner

A laser three-dimensional and scanner technology, applied in the direction of optical devices, measuring devices, optics, etc., can solve the problems of inaccurate positioning of imaging positions, difficulty in ensuring accurate values of optical geometric parameters, difficulty in reflecting CCD resolution and depth of focus, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

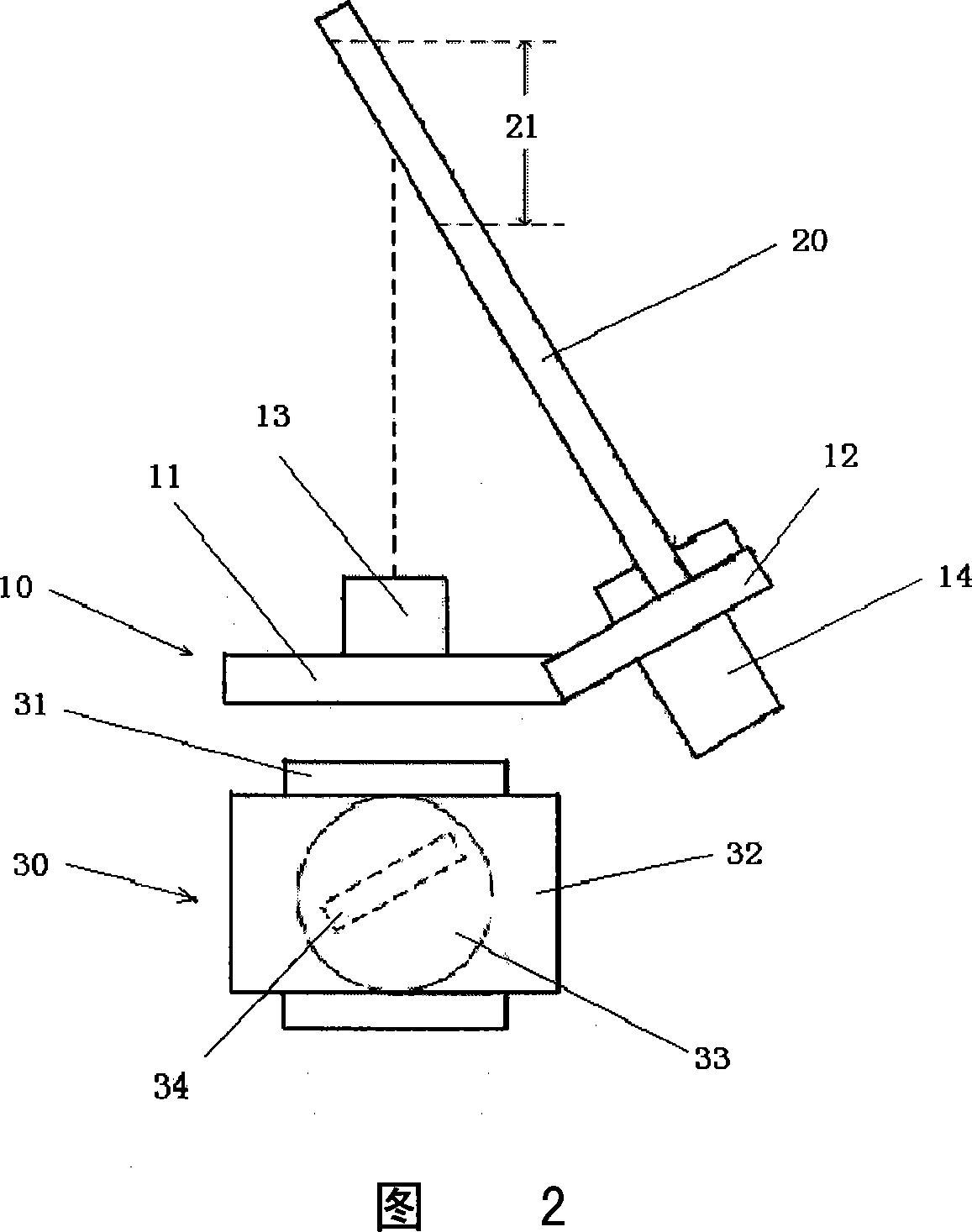

[0014] As shown in Figure 2, the device of the present invention includes a lens-laser bracket 10, a laser exit surface plate 20 and an imaging device micro-movement platform 30, and the plane 11 and the bending surface 12 on the lens-laser bracket 10 are based on the final product The parameters are precisely designed and processed as a part. An optical lens 13 is arranged on the lens-laser plane 11 , and a laser emitting surface plate 20 is arranged on the bending surface 12 , and a mark of a measuring range 21 is arranged on the laser emitting surface plate 20 . The imaging device micro-motion platform 30 is a three-dimensional motion platform purchased on the market, which includes a left and right micro-motion platform 31, a front and rear micro-motion platform 32, and a rotation micro-motion platform 33. An imaging device 34 is arranged in the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com