Ammonium sulfate heat conductive oil drying method

A drying method and heat transfer oil technology, which are applied in the direction of heating to dry solid materials, dry solid materials, and dry gas layout, etc., can solve problems such as uneconomical, unrecyclable, and unenvironmental protection, so as to eliminate the generation and reduce waste liquid. The effect of eliminating steam condensate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

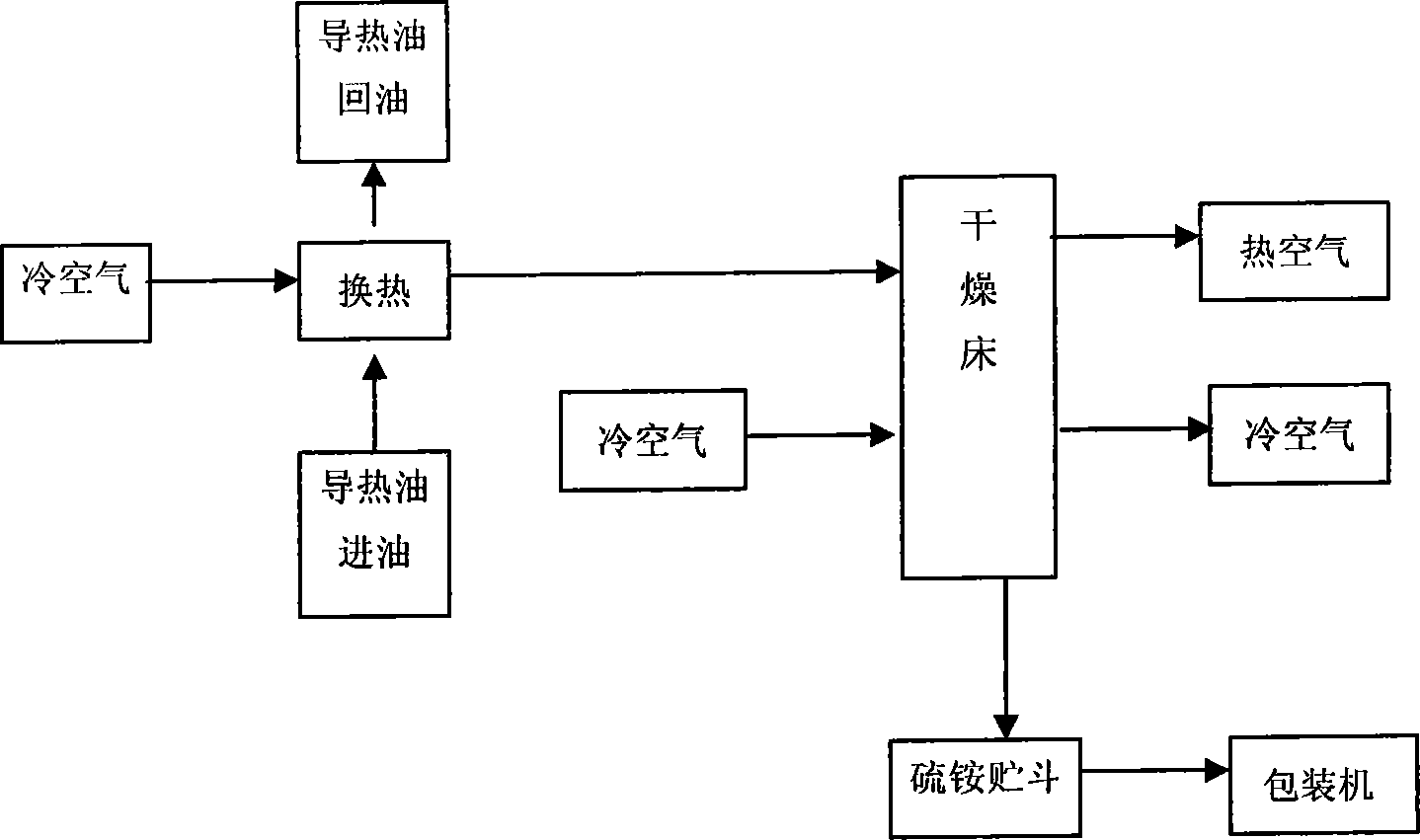

[0011] As shown in the picture. The overall steps of the ammonium sulfate drying method are:

[0012] The ammonium sulfate crystals discharged from the centrifuge are sent to the vibrating fluidized bed dryer by the screw pusher, and the cold air is heated by the hot air heater and then becomes hot air and passed into the fluidized bed to dry the ammonium sulfate crystals. After drying, it is cooled by the cold air sent by the cooling fan and then enters the ammonium sulfate storage hopper. The ammonium sulfate crystals coming down from the ammonium sulfate storage hopper are automatically weighed and packaged by the packaging machine and sent to the finished product warehouse.

[0013] The cold air heating is done via a heater.

[0014] The cold air heating technology is changed from steam heating to heat transfer oil and cold air. There are heat transfer oil inlet and oil return ports on the heater. It is heated to the specified temperature and enters the drying bed, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com