W-shape flame boiler for preventing side wall water cooling wall slagging scorification

A water-cooled wall and side wall technology, applied in steam boilers, combustion methods, combustion chambers, etc., can solve problems such as incomplete combustion, flame prolongation, and accelerated slagging on the heating surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

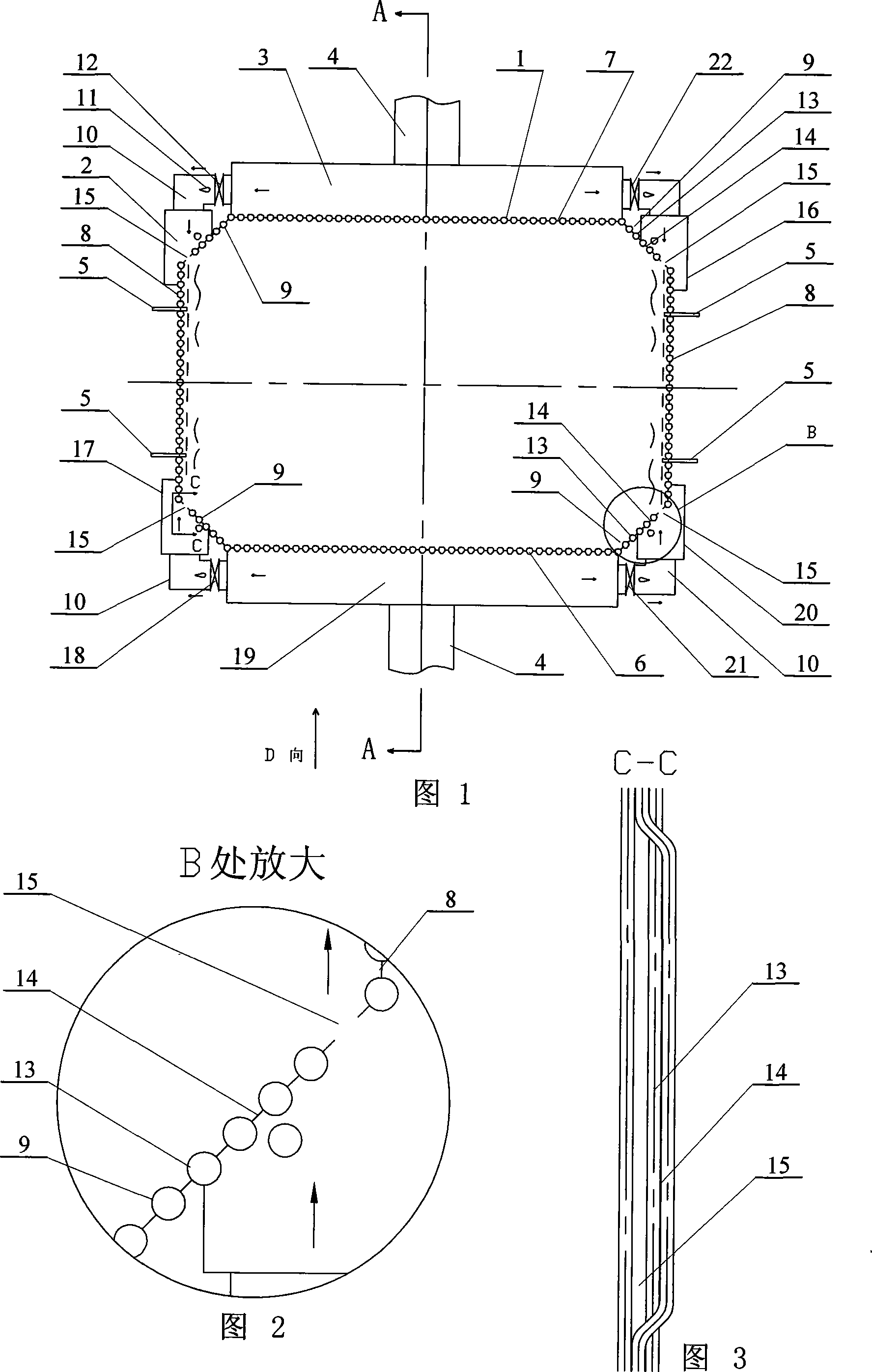

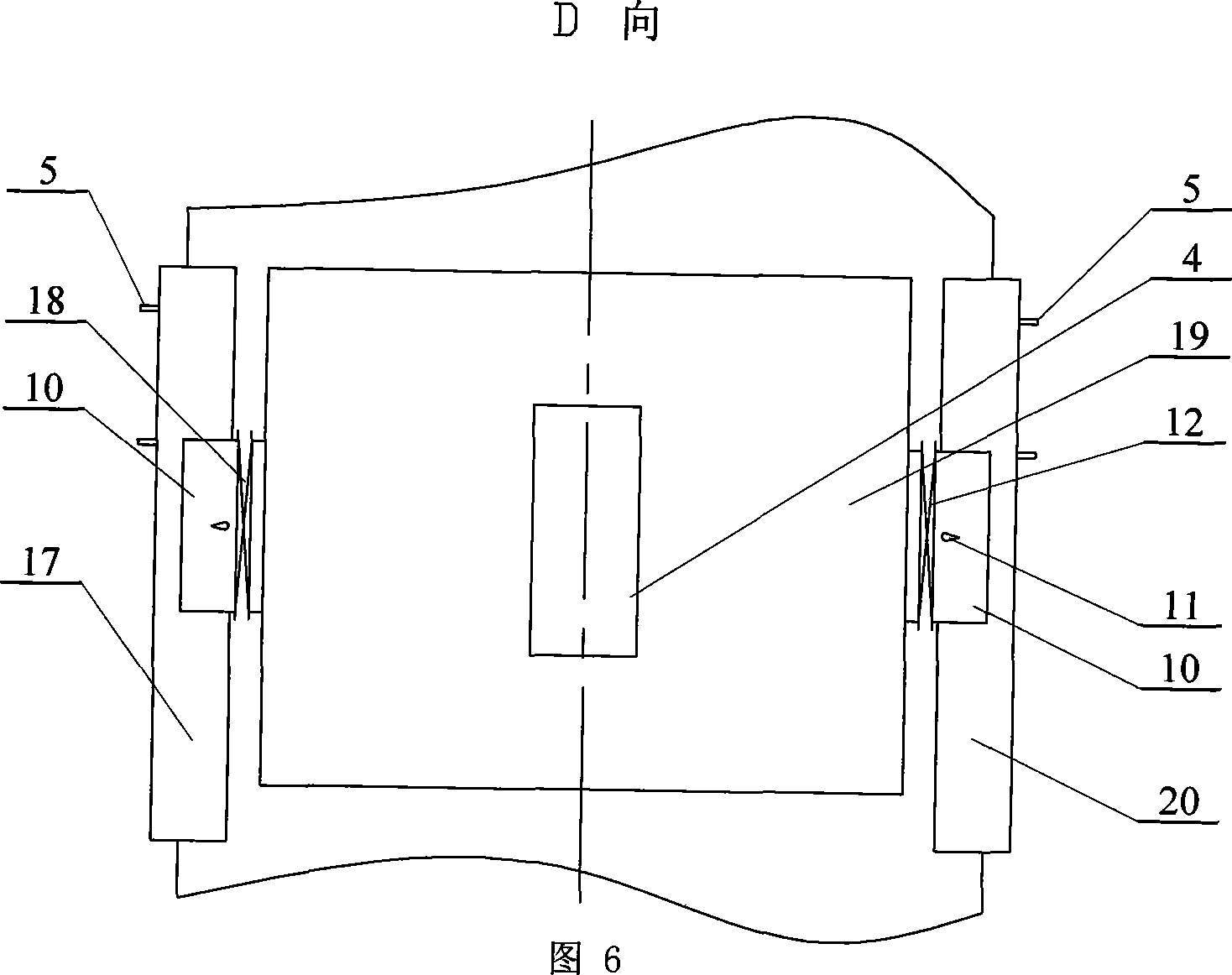

[0005] Specific embodiment one: (refer to Fig. 1~Fig. 4, Fig. 6) this embodiment consists of a furnace body 1, a first wall-attached air box 2, a first main air box 3, two secondary air ducts 4, four wall-attached Wind duct 10, the second wall-attached wind box 16, the third wall-attached wind box 20, the fourth wall-attached wind box 17 and the second main wind box 19, the body of furnace 1 is composed of front wall 6, rear wall 7, Composed of two side walls 8 and four wing walls (water-cooled walls) 9, the front wall 6, the rear wall 7 and the side walls 8 are arranged in a quadrangular shape, between the two side walls 8 and the front wall 6, the two side walls 8 It is connected with the rear wall 7 by the wing wall 9, and the wing wall 9 is composed of the water-cooled wall tube 13 and the fin 14; the first wall-mounted wind box 2, the second wall-mounted wind box 16, the third The wall-attached wind box 20 and the fourth wall-attached wind box 17 are respectively arranged...

specific Embodiment approach 2

[0006] Embodiment 2: (see FIG. 1 ) The difference between this embodiment and Embodiment 1 is that each wall-attached air duct 10 is provided with a damper 11 . Play the purpose of controlling wind flow. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0007] Specific embodiment three: (referring to Fig. 1) the difference between this embodiment and specific embodiment two is that it increases the first speed detector 12, the second speed detector 22, the third speed detector 21 and the fourth speed detector 18, the first speed detector A speed detector 12 is arranged between the first wall-attached wind box 2 and one end of the first main wind box 3, and a second speed detector 22 is arranged between the second wall-attached wind box 16 and the other end of the first main wind box 3, The third speed detector 21 is arranged between the third wind box 20 and one end of the second main wind box 19, and the fourth speed detector 18 is arranged between the fourth wind box 17 and the other end of the second main wind box 19. . The first speed detector 12, the second speed detector 22, the third speed detector 21 and the fourth speed detector 18 added in this embodiment are used to monitor the flow velocity of the wind in each wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com