Method for producing bacterial strain of Pediococcus acidilactici, and bacterin of Pediococcus acidilactici

A technology of Pediococcus lactis and Pediococcus lactis, applied in the direction of bacteria, fermentation, etc., can solve the problems of bacterial strain classification and fermentation process that have not been reported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] A single colony of Pediococcus lactis LH31 was inoculated in the improved MRS liquid medium, and cultured at 30°C and 200 rpm for 8 hours to activate;

[0068] The components and concentrations of the improved MRS liquid medium are:

[0069] Peptone 10.0g / L, yeast powder 5.0g / L, glucose 15.0g / L, beef extract 10.0g / L, amino acid powder 5.0g / L, corn steep liquor 10.0g / L, ammonium citrate 2.0g / L, sodium acetate 5.0g / L, anhydrous magnesium sulfate 0.1g / L, anhydrous manganese sulfate 0.05g / L, dipotassium hydrogen phosphate 2.0g / L, pH value is 6.5, pH value is 1mol / L NaOH and 1mol / L HCl regulation;

[0070] The above-mentioned activated Pediococcus LH31 was inoculated in a 3.7L fermenter, and the inoculation amount was 5% based on the volume of the medium, and the initial medium of the fermenter was an improved MRS liquid medium, and the pH value was 6.5;

[0071] Start feeding after 8 hours of cultivation, the feeding medium is concentrated TG medium, and the flow rate is ...

Embodiment 2

[0078] The improved MRS liquid medium and TG concentrated medium are as in Example 1.

[0079] A single colony of Pediococcus LH31 was inoculated in the improved MRS liquid medium, cultured at 30°C and 200 rpm for 8 hours, and activated;

[0080] The above activated Pediococcus LH31 was inoculated in a 5L fermenter with an inoculum size of 5%, and the initial medium of the fermenter was a modified MRS medium with a pH value of 6.3;

[0081] After intermittent culture for 8 hours, start feeding, the feeding medium is concentrated TG medium, and the flow rate is 1.2ml / min;

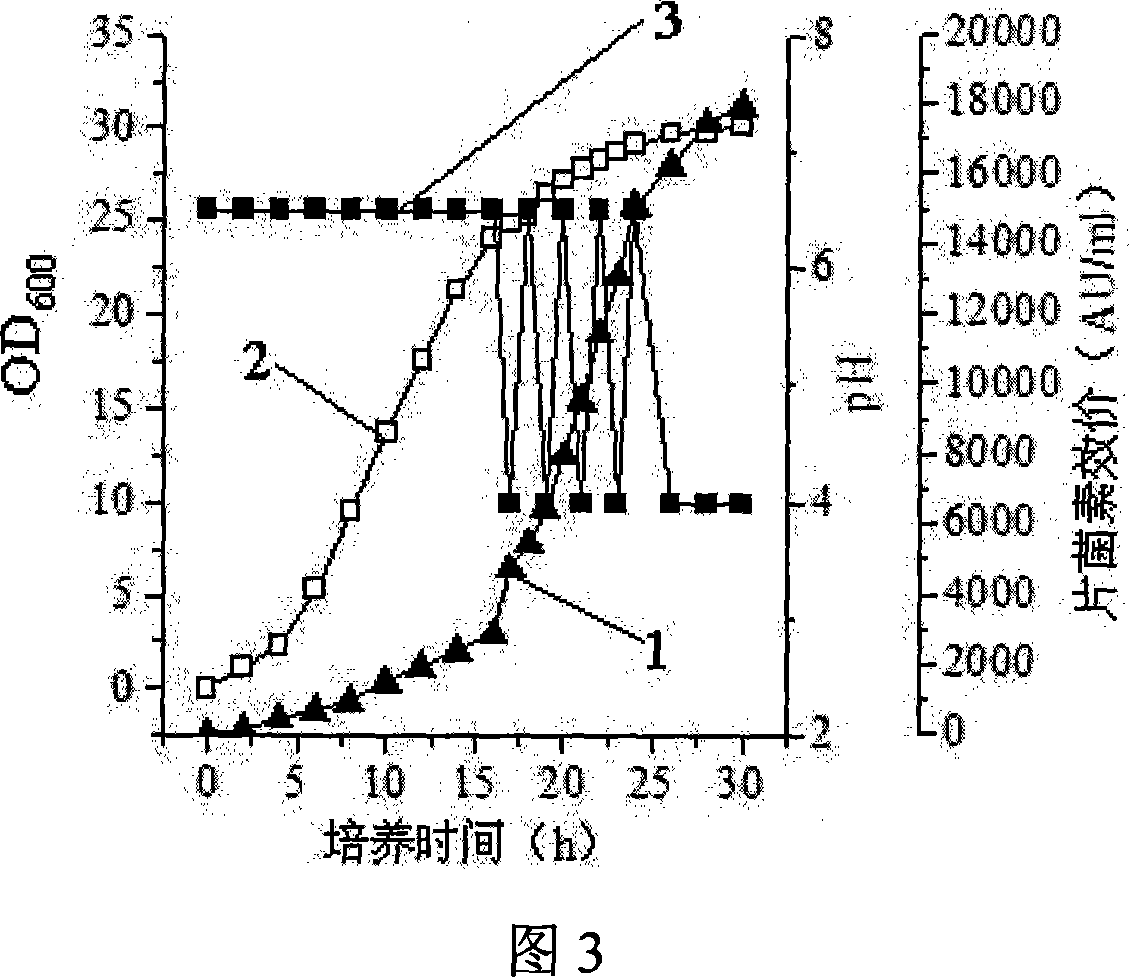

[0082] When cultivating to the late stage of fermentation, that is, 15 hours, the pH value is adjusted to 4.0, and the fermentation ends at 24 hours.

[0083] After the above fermentation culture, the final cell concentration OD 600 reached 18, the pediocin titer was 1.2×10 4 AU / ml.

Embodiment 3

[0085] The improved MRS liquid medium and TG concentrated medium are as in Example 1.

[0086] A single colony of Pediococcus LH31 was inoculated in the improved MRS liquid medium, and cultured at 30°C and 200 rpm for 8 hours;

[0087] Inoculate the above-mentioned activated Pediococcus LH31 in a 10L fermenter with an inoculum size of 5%, and the initial culture medium of the fermenter is an improved MRS liquid medium with a pH value of 6.5;

[0088] After batch culture for 6 hours, start feeding, the feeding medium is concentrated TG medium, and the flow rate is 1.5ml / min;

[0089] When cultivating to the late stage of fermentation, that is, 18 hours, the pH value is adjusted to 6.5-4.0 for periodic changes, and the fermentation ends at 24 hours. The pH value adjusted to 4.0-6.5 periodic changes refers to: at the 18th hour, the pH control method is changed from constant value control to natural change, and the pH value is reduced to 4.0 at the 20th hour. Use 1mol / L NaOH to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Potency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com