Method for preparing potassium fluoride in high activity

A technology of highly active potassium fluoride and potassium fluoride, applied in directions such as alkali metal fluorides, can solve problems such as the inability to prepare highly active potassium fluoride products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

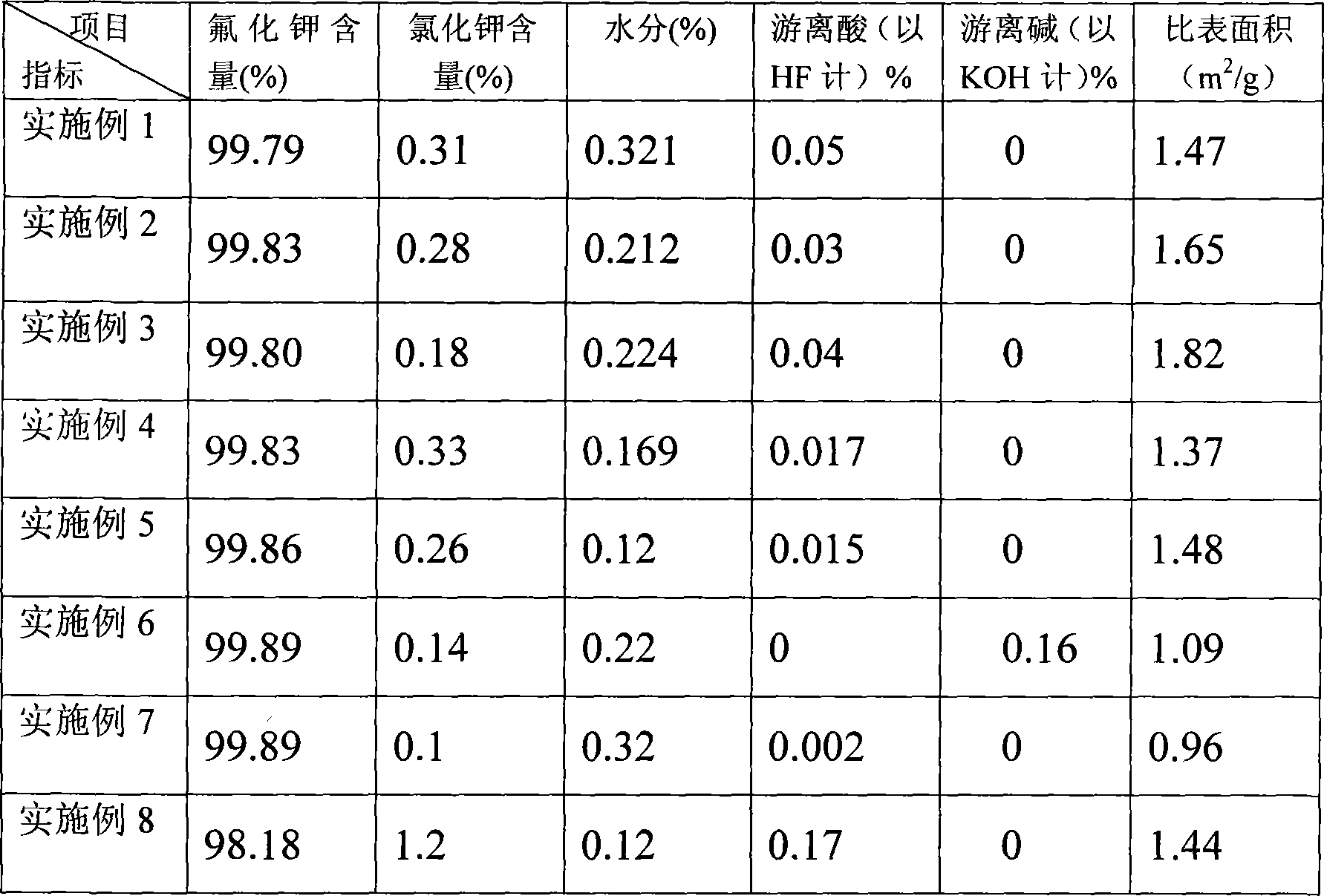

Embodiment 1

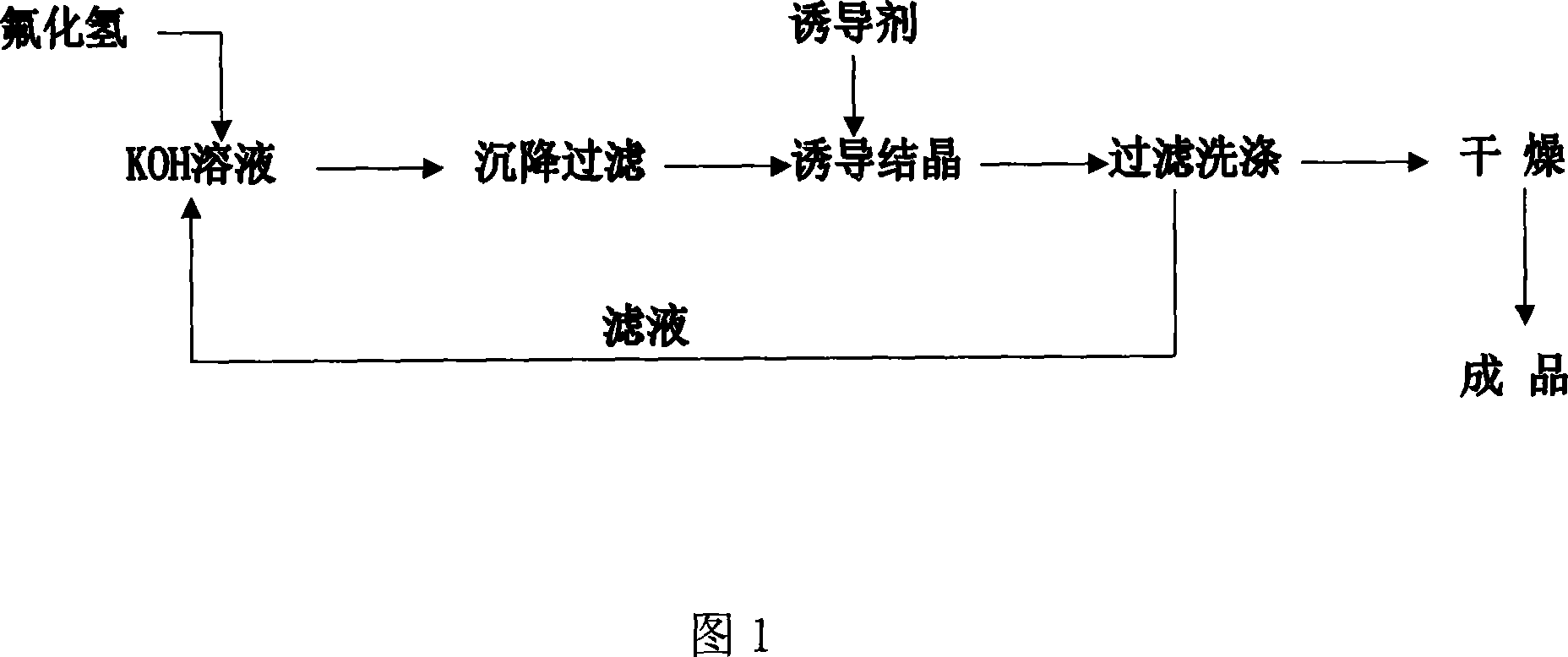

[0025] 1) Dissolving 1000g of potassium hydroxide in 800g of water to obtain a potassium hydroxide solution, and introducing hydrogen fluoride gas into the potassium hydroxide solution, the rate of introduction of hydrogen fluoride gas is advisable to keep the reaction temperature at 40-70°C;

[0026] 2) When the pH value of the reaction solution reaches 7.1, stop feeding the hydrogen fluoride gas, and the neutralization reaction is completed;

[0027] 3) After the reaction solution was allowed to settle for 12 hours, the supernatant was taken;

[0028] 4) Cool the supernatant to 21°C, add 0.5g potassium fluoride inducer, and the potassium fluoride aqueous solution will crystallize in an instant;

[0029] 5) After suction filtration and washing with a saturated potassium fluoride aqueous solution, put the filter cake into a vacuum oven to dry for 4 hours to obtain highly active potassium fluoride.

Embodiment 2

[0031] In the case that other conditions are the same as in Example 1, washing is carried out with absolute ethanol during the suction filtration in step 5).

Embodiment 3

[0033] In the case that other conditions are the same as in Example 1, after the instant crystallization in step 4) is completed, a certain amount of absolute ethanol is added to the crystallized potassium fluoride aqueous solution and fully stirred before suction filtration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com